Ford Mustang (1999-2004) Service Manual: Overdrive Servo

Special Tool(s)

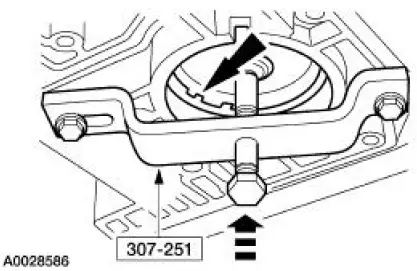

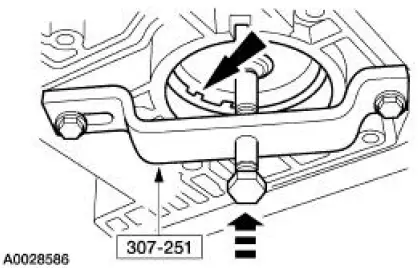

|

Remover/Installer, Servo Piston 307-251 (T92P-70023-A) |

Removal

1. Remove the main control valve body. For additional information, refer to Main Control Valve Body in this section.

2. NOTE: If the tool is not available, extreme care must be taken. Spring pressure will force overdrive servo piston assembly out of case. Case bore damage may result from trying to pry on overdrive servo internal retaining ring.

Using the special tool, compress the servo spring to remove the overdrive servo retaining ring.

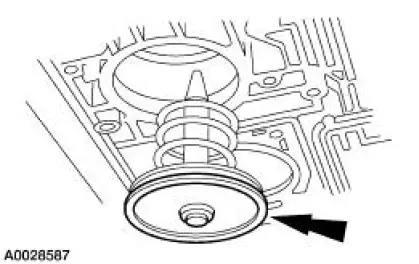

3. Remove the overdrive servo piston and return spring.

Installation

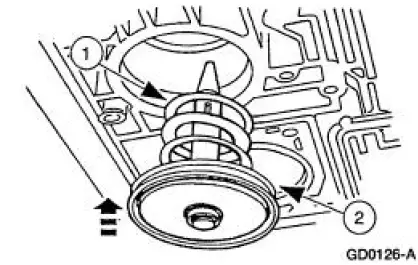

1. Install the overdrive servo piston assembly.

1. Install the overdrive servo piston return spring.

2. Install the overdrive servo piston assembly.

2. Use the special tool to install the overdrive servo piston retaining ring.

3. Install the main control valve body. For additional information, refer to Main Control Valve Body in this section.

Reverse Servo Assembly

Reverse Servo Assembly

Special Tool(s)

Dial Indicator Gauge with

Holding Fixture

100-002 (TOOL-4201-C)

Remover/Installer, Servo

Piston

307-251 (T92P-70023-A)

Installer, Servo Pisto ...

1-2 Accumulator

1-2 Accumulator

Removal

1. Compress the 1-2 accumulator cover and remove the accumulator piston

retaining ring.

2. NOTE: Note the location of the 1-2 accumulator springs for

reference during assembly.

Remove the ...

Other materials:

Glass, Frames and Mechanisms (Diagnosis and Testing)

Refer to Wiring Diagrams Cell 100 , Power Windows for schematic and

connector information.

Refer to Wiring Diagrams Cell 56 , Rear Window Defrost for schematic and

connector information.

Special Tool(s)

Worldwide Diagnostic System

(WDS)

4 ...

Cable and Conduit - Front

Removal

1. CAUTION: If any component in the parking brake system requires

repair or if the

rear axle housing (4010) is removed, the cable tension must be released.

Release the cable tension. For additional information, refer to Parking

Brake Cable Tens ...

Interior Trim and Ornamentation

General Specifications

Torque Specifications

Interior Trim

The interior trim consists of:

A-pillar lower trim panels

door trim panels

headliner (coupe)

package tray trim panel (coupe)

quarter trim panels

upper quarter trim panels (coup ...