Ford Mustang (1999-2004) Service Manual: Pinpoint Test B: LFC 21/DTC B1921 - RCM Bracket Ground Resistance High

Normal Operation

WARNING: The tightening torque of the restraints control module (RCM) retaining bolts is critical for proper air bag supplemental restraint system (SRS) operation. Refer to Restraints Control Module (RCM) in this section for correct torque values.

The restraints control module (RCM) monitors the resistance between the ground connections at its housing and the reference ground at pin 21. If the RCM detects a resistance greater than 100 ohms, it will store a diagnostic trouble code (DTC) B1921 in memory and flash a lamp fault code (LFC) 21 (or higher priority code if one exists) on the air bag indicator.

Possible Causes

High resistance between the RCM housing ground and pin ground can be caused by:

- incorrect seating of the RCM retaining bolts.

- incorrect tightening torque of the RCM retaining bolts.

- high resistance on RCM logic ground circuit 397 (BK/WH).

PINPOINT TEST B: LFC 21/DTC B1921 - RCM BRACKET GROUND RESISTANCE HIGH

| Test Step | Result / Action to Take |

| B1 CHECK FOR A HARD OR INTERMITTENT DTC | Yes This is a hard fault. The fault condition is still present. This fault cannot be cleared until it is corrected and the DTC is no longer retrieved during the on-demand self test. GO to B2 . No This is an intermittent fault. The fault condition is not present at this time. GO to B6 . |

|

|

| B2 INSPECT THE RCM MOUNTING, MOUNTING BRACKET AND MOUNTING SURFACE | Yes Make sure the RCM, mounting bracket and mounting surface are free of damage, corrosion or dirt and the three retaining bolts are fully seated and correctly tightened. Reattach the RCM and mounting bracket to the mounting surface. GO to B7 . No GO to B3 . |

|

|

| B3 CHECK THE RCM HARNESS CONNECTION | Yes GO to B4 . No ATTACH the RCM harness connector correctly. GO to B7 . |

|

|

| B4 CHECK THE VEHICLE CHASSIS GROUND | Yes REPAIR the chassis grounding system. GO to B7 . No GO to B5 . |

|

|

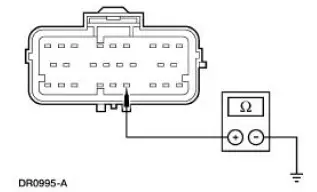

| B5 CHECK THE GROUND CIRCUIT 397 (BK/WH) FOR AN OPEN | Yes REPAIR the circuit. GO to B7 . No INSTALL a new RCM. GO to B7 . |

|

|

| B6 CHECK FOR AN INTERMITTENT FAULT | Yes CHECK for causes or intermittent high resistance on circuit 397 (BK/WH). Attempt to recreate the hard fault by flexing the wire harness and cycling the ignition key frequently. REPAIR any intermittent concerns found. GO to B7 . No GO to B7 . |

|

|

| B7 CHECK FOR ADDITIONAL DTCs | Yes Do not clear any DTCs until all DTCs have been resolved. GO to the Restraints Control Module (RCM) Diagnostic Trouble Code (DTC) Priority Table in this section for pinpoint test direction. No RECONNECT the system. REACTIVATE the system. PROVE OUT the system. REFER to Air Bag Supplemental Restraint System (SRS) in this section. CLEAR all DTCs. |

|

Pinpoint Test A: The Air Bag Warning Indicator Is Illuminated Continuously

- RCM

Disconnected, Inoperative or Lost/Low Ignition Feed

Pinpoint Test A: The Air Bag Warning Indicator Is Illuminated Continuously

- RCM

Disconnected, Inoperative or Lost/Low Ignition Feed

Normal Operation

NOTE: During normal operation the air bag indicator will be lit continuously

for 6 seconds after the

ignition switch is placed in the RUN position and after five cycles of a lamp

fa ...

Pinpoint Test C: LFC 29/DTC C1414 - Incorrect Vehicle Identification Code

Pinpoint Test C: LFC 29/DTC C1414 - Incorrect Vehicle Identification Code

Normal Operation

The restraints control module (RCM) monitors the electrical state of pins

10, 13 and 14 to determine if

it is installed on the correct vehicle. If the RCM detects an incorrect

c ...

Other materials:

Rear View Mirrors

Torque Specifications

Rear View Mirrors

The rear view mirror system consists of the following components:

exterior rear view mirror

exterior rear view mirror control

exterior rear view mirror glass

exterior rear view mirror motor

interior ...

Input Shaft and Bearing

Special Tool(s)

Plate, Bearing/Oil Seal

205-090 (T75L-1165-B)

Puller, Bearing

205-D064 (D84L-1123-A)

Installer, Drive Pinion Bearing

Cone

205-004 (T53T-4621-B)

Adapter Set, Step Plate

205-DS011 (D80L-630 ...

Moulding - Rocker Panel

Removal

1. Remove the front rocker panel moulding screw.

2. Remove the strip.

3. Remove the rear rocker panel moulding screw.

4. Remove the pin-type retainers and the rocker panel moulding.

Installation

1. To install, reverse the removal procedure. ...