Ford Mustang (1999-2004) Service Manual: Connecting Rod - Twist

1. Measure the connecting rod twist on a suitable alignment fixture. Follow the instructions of the fixture manufacturer. Verify the measurement is within specification.

- Refer to the appropriate section in Group for the procedure.

- If out of specification, install new components as necessary. Refer to the appropriate section in Group for the procedure.

Connecting Rod -Piston Pin Side Clearance

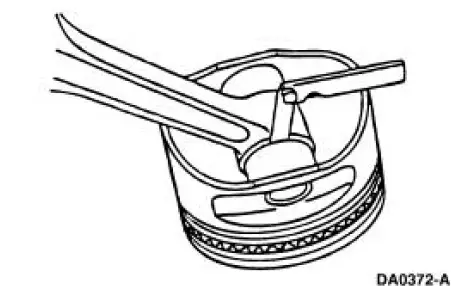

1. Measure the clearance between the connecting rod and the piston. Verify the measurement is within specification.

- Refer to the appropriate section in Group for the procedure.

- If out of specification, install new components as necessary. Refer to the appropriate section in Group 303 for the procedure.

Connecting Rod - Bushing Diameter

Connecting Rod - Bushing Diameter

1. Measure the inner diameter of the connecting rod bushing, if equipped.

Verify the diameter is

within specification.

Refer to the appropriate section in Group for the procedure.

If out of s ...

Connecting Rod - Bearing Journal Clearance

Connecting Rod - Bearing Journal Clearance

Special Tool(s)

Plastigage

303-D031 (D81L-6002-B) or

equivalent

NOTE: The crankshaft connecting rod journals must be within

specifications to check the connecting

rod bearing journa ...

Other materials:

Material

Item

Specification

Threadlock and

Sealer

E0AZ-19554-AA

WSK-M2G351-A5 (type

II)

Shoulder Bolt Kit

F5ZZ-76539A04-A

-

NOTE: Before starting the adjustment process, inspect the top for damage,

make sure that the door

window glass ...

Removal

NOTE: This procedure applies to both the LH and RH halfshafts.

1. CAUTION: The vehicle must be on level ground and at curb height.

Mark the rear shock absorber relative to the protective sleeve.

During installation, raise the suspension to this reference ...

Removal

CAUTION: Since the engine is not free-wheeling, timing procedures must

be followed

exactly or piston and valve damage can occur.

1. Remove the engine front cover. For additional information, refer to Engine

Front Cover in this

section.

2. Remove the cranksh ...