Ford Mustang (1999-2004) Service Manual: Pinpoint Tests

PINPOINT TEST A: THE ENGINE DOES NOT CRANK AND THE RELAY DOES CLICK

| Test Step | Result / Action to Take |

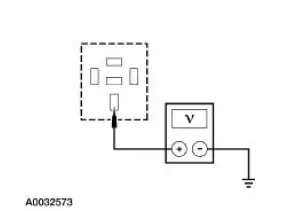

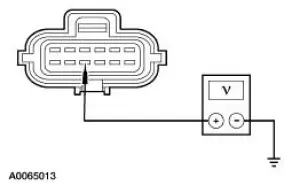

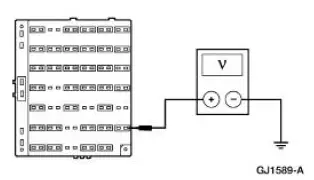

| A1 CHECK THE VOLTAGE TO THE STARTER RELAY | Yes GO to A2 . No REPAIR circuit 1050 (LG/VT) for an open. TEST the system for normal operation. |

|

|

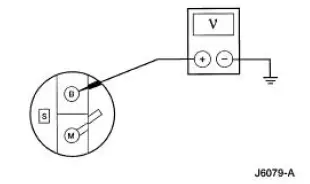

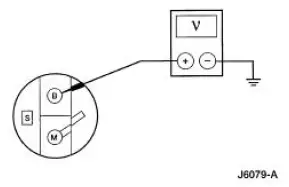

| A2 CHECK THE VOLTAGE TO THE STARTER MOTOR SOLENOID | Yes GO to A3 . No REPAIR circuit 2037 (RD) for an open. TEST the system for normal operation. |

|

|

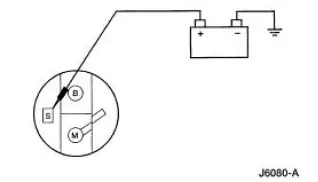

| A3 MANUALLY JUMP THE STARTER MOTOR | Yes GO to A4 . No INSTALL a new starter motor. REFER to Starter Motor-3.8L or Starter Motor-4.6L . TEST the system for normal operation. |

|

|

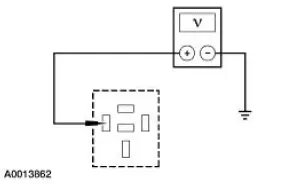

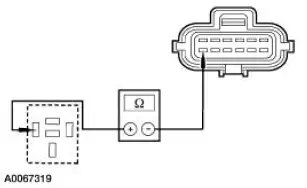

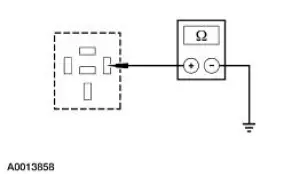

| A4 TEST THE STARTER MOTOR RELAY | Yes REPAIR circuit 33 (WH/PK)/262 (BN/PK) for an open. TEST the system for normal operation. No INSTALL a new starter motor relay. TEST the system for normal operation. |

|

PINPOINT TEST B: THE ENGINE DOES NOT CRANK AND THE RELAY DOES NOT CLICK

| Test Step | Result / Action to Take |

| B1 CHECK CIRCUIT 33 (WH/PK) FOR VOLTAGE | Yes GO to B10 . No For automatic transmissions, GO to B2 . For manual transmissions, GO to B5 . |

|

|

| B2 CHECK CIRCUIT 32 (RD/LB) FOR VOLTAGE AT THE DIGITAL TR SENSOR | Yes GO to B3 . No GO to B7 . |

|

|

| B3 CHECK CIRCUIT 33 (WH/PK) FOR OPEN | Yes GO to B4 . No REPAIR circuit 33 (WH/PK). TEST the system for normal operation. |

|

|

| B4 CHECK DIGITAL TRANSMISSION RANGE (TR) SENSOR ADJUSTMENT | Yes INSTALL a new digital TR sensor. TEST the system for normal operation. No ADJUST the digital TR as necessary. TEST the system for normal operation. |

|

|

| B5 CHECK CIRCUIT 32 (RD/LB) FOR VOLTAGE AT THE CLUTCH SWITCH OR JUMPER | Yes GO to B6 . No GO to B7 . |

|

|

| B6 CHECK CIRCUIT 33 (WH/PK)/32 (RD/LB) FOR OPEN | Yes INSTALL a new clutch pedal switch. TEST the system for normal operation. No REPAIR circuit 33 (WH/PK)/32 (RD/LB). TEST the system for normal operation. |

|

|

| B7 CHECK FOR VOLTAGE AT FUSE 6 | Yes REPAIR circuit 32 (RD/LB). TEST the system for normal operation. No GO to B8 . |

|

|

| B8 CHECK CIRCUIT 1050 (LG/VT) FOR VOLTAGE | Yes GO to B9 . No REPAIR circuit 1050 (LG/VT). TEST the system for normal operation. |

|

|

| B9 CHECK THE IGNITION SWITCH | Yes REPAIR circuit 33 (WH/PK). TEST the system for normal operation. No INSTALL a new ignition switch. TEST the system for normal operation. |

|

|

| B10 CHECK CIRCUIT 1205 (BK) FOR OPEN | Yes INSTALL a new starter motor relay. TEST the system for normal operation. No REPAIR circuit 1205 (BK). TEST the system for normal operation. |

|

PINPOINT TEST C: THE ENGINE CRANKS SLOWLY

| Test Step | Result / Action to Take |

| NOTE: Before beginning this test, be sure that the battery is tested and fully charged. | |

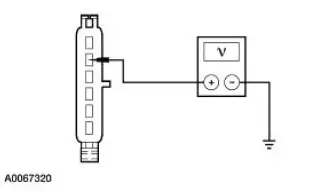

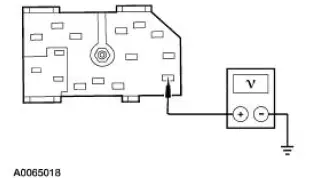

| C1 CHECK THE VOLTAGE TO THE STARTER | Yes GO to C2 . No REPAIR the circuit between the battery and the starter solenoid. CLEAN and TIGHTEN the connections at the battery terminals. TEST the system for normal operation. |

|

|

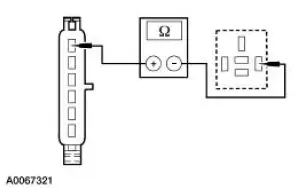

| C2 CHECK MOTOR GROUND CIRCUIT | Yes INSTALL a new starter motor. REFER to Starter Motor-3.8L or Starter Motor-4.6L . TEST the system for normal operation. No REPAIR the ground circuit as necessary. TEST the system for normal operation. |

|

|

PINPOINT TEST D: UNUSUAL STARTER NOISE

| Test Step | Result / Action to Take |

| D1 CHECK THE STARTER MOTOR MOUNTING | GO to D2 . No REINSTALL the starter motor correctly. REFER to Starter Motor-3.8L or Starter Motor-4.6L in this section. |

|

|

| D2 INSPECT THE STARTER MOTOR | Yes INSTALL a new starter motor. REFER to Starter Motor-3.8L or Starter Motor-4.6L in this section. TEST the system for normal operation. No CHECK the starter drive. REFER to Component Tests, Starter Drive Test in this section. INSTALL a new starter motor. TEST the system for normal operation. |

|

Inspection and Verification

Inspection and Verification

WARNING: When servicing starter motor or carrying out other underhood

work in the

vicinity of the starter motor, be aware that the heavy gauge battery input lead

at the starter

solenoid is "electric ...

Component Tests

Component Tests

Starter Motor -Voltage Drop Test

WARNING: When servicing starter motor or carrying out other underhood

work in the

vicinity of the starter motor, be aware that the heavy gauge battery input lead

at ...

Other materials:

Cooling System Draining, Filling and Bleeding

Material

Item

Specification

Motorcraft Premium Gold

Engine Coolant

VC-7-A (in Oregon VC-7-B)

(yellow color)

WSS-M97B51-

A1

Draining

WARNING: Never remove the pressure relief cap while the engine is

operating or when the

cooling syst ...

Rocker Arms - Inspection

CAUTION: Do not attempt to true surfaces by grinding. Check the

rocker arm pad, side

rails and seat for excessive wear, cracks, nicks or burrs. Check the rocker

arm seat bolt for

stripped or broken threads. Install new components as ncessary or possible ...

External Controls (Diagnosis and Testing)

Refer to Wiring Diagrams Cell 37 , Shift Lock for schematic and connector

information.

Refer to Wiring Diagrams Cell 29 , Transmission Control for schematic and

connector information.

Special Tool(s)

73 Digital Multimeter

105-R0051 or equivalent ...