Ford Mustang (1999-2004) Service Manual: Pressure Relief

Special Tool(s)

|

Fuel Pressure Gauge 310-012 (T80L-9974-B) |

WARNING: Do not smoke or carry lighted tobacco or open flame of any type when working on or near any fuel-related components. Highly flammable mixtures are always present and may be ignited, resulting in possible personal injury.

WARNING: Fuel in the fuel system remains under high pressure even when the engine is not running. Before servicing or disconnecting any of the fuel lines or fuel system components, the fuel system pressure must be relieved to prevent accidental spraying of fuel, causing personal injury or a fire hazard.

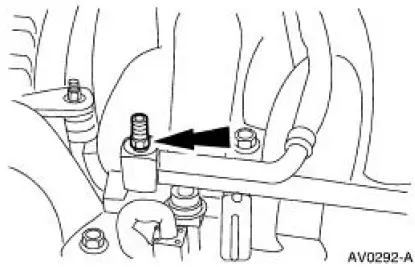

1. Remove the Schrader valve cap and install the Fuel Pressure Gauge.

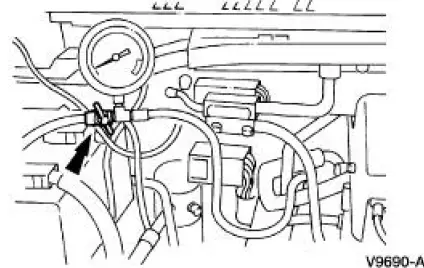

2. CAUTION: Open the manual valve slowly on the Fuel Pressure Gauge.

Relieve the fuel pressure.

- Place the fuel in a suitable container.

Fuel System (Description and Operation)

Fuel System (Description and Operation)

Component Location

WARNING: Do not smoke or carry lighted tobacco or open flame of any

type when

working on or near any fuel-related components. Highly flammable mixtures are

always prese ...

Fuel Tank Draining

Fuel Tank Draining

Special Tool(s)

Fuel Storage Tanker

164-R3202 or equivalent

Fuel Tank Drain Hose

310-F013

WARNING: Do not smoke or carry lighted tobacco or an open flame of any

type whe ...

Other materials:

Manual Transmission

The TR3650 five-speed manual transmission features the following:

The fifth speed gear functions as an overdrive gear.

The forward gears are synchronized and helical cut.

The reverse gear operates through a constant-mesh, fully

synchronized system.

...

AM/FM/CD/Sirius satellite radio

WARNING: Driving while distracted can result in loss of vehicle

control, crash and injury. We strongly recommend that you use

extreme caution when using any device that may take your focus off

the road. Your primary responsibility is the safe operation of you ...

Differential Housing Cover

Removal

1. Raise and support the vehicle.

2. NOTE: Empty the lubricant into a clean container for reuse.

Remove the differential housing cover (4033).

1. Remove the 10 bolts and drain the lubricant from the differential

housing (4010).

2. Remove the d ...