Ford Mustang (1999-2004) Service Manual: Fuel Tank Draining

Special Tool(s)

|

Fuel Storage Tanker 164-R3202 or equivalent |

|

Fuel Tank Drain Hose 310-F013 |

WARNING: Do not smoke or carry lighted tobacco or an open flame of any type when working on or near any fuel-related components. Highly flammable mixtures are always present and may be ignited, resulting in possible personal injury.

1. Disconnect the battery ground cable. For additional information, refer to Section.

2. Remove the fuel tank filler cap.

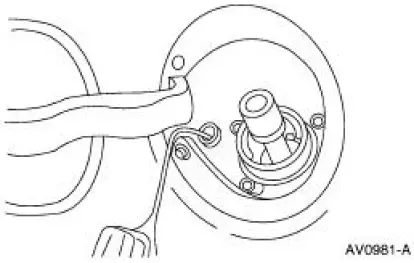

3. Insert the hose guide into the filler neck.

4. NOTE: Insert the hose until the stop contacts the guide tube. If the stop does not contact the guide tube, remove the hose and repeat the procedure.

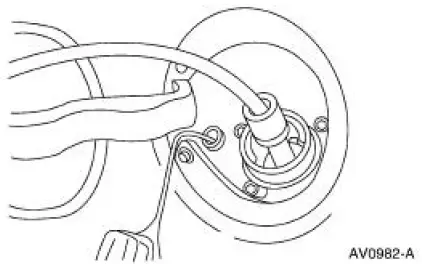

Insert the chamfered end of the hose into the filler neck through the guide tube.

5. Attach the Fuel Storage Tanker to the hose and remove the fuel.

6. Remove the hose and the hose guide.

Pressure Relief

Pressure Relief

Special Tool(s)

Fuel Pressure Gauge

310-012 (T80L-9974-B)

WARNING: Do not smoke or carry lighted tobacco or open flame of any

type when

working on or near any fuel-related components. ...

Spring Lock Couplings

Spring Lock Couplings

Special Tool(s)

Disconnect Tool, Spring Lock

Coupling (3/8 inch yellow)

310-D004 (D87L-9280-A) or

equivalent

Disconnect Tool, Spring Lock

Coupling (1/2 inch green)

310 ...

Other materials:

Installation

1. CAUTION: Do not allow grease, oil, brake fluid or other

contaminants to contact the

pad lining material. Do not install contaminated pads.

NOTE: Install all hardware supplied with pad kits.

Install the pads.

1. Install the new pad slippers. ...

Clutch Pedal Position (CPP) Switch

Removal

1. Disconnect the battery ground cable. For additional information,

refer to Section.

2. Disconnect the connector.

3. Remove the bolt and the clutch pedal position (CPP) switch.

Installation

1. To install, reverse the removal procedure. ...

Removal

CAUTION: Suspension fasteners are critical parts because they affect

performance of vital

components and systems and their failure can result in major service expense. A

new part with

the same part number must be installed if installation becomes necessary. ...