Ford Mustang (1999-2004) Service Manual: Installation

1. Inspect the pinion flange seal journal for rust, nicks, and scratches prior to installing the flange.

Polish the seal journal with fine crocus cloth, if necessary.

2. Lubricate the pinion flange splines.

- Use SAE 80W-90 Premium Rear Axle Lubricant XY-80W90-QL or equivalent meeting Ford specification WSP-M2C197-A.

3. NOTE: Disregard the index marks if installing a new pinion flange.

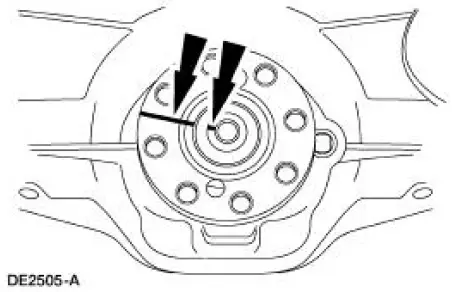

Position the pinion flange.

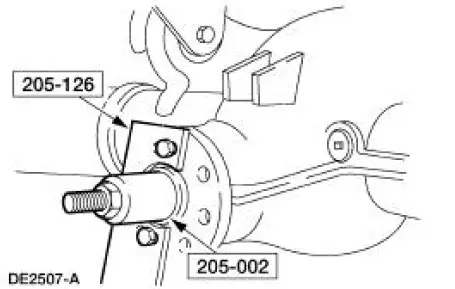

4. Using the special tools, install the pinion flange.

5. CAUTION: Do not under any circumstance loosen the nut to reduce preload. If it is necessary to reduce preload, install a new collapsible spacer (4662) and nut.

CAUTION: Remove the special tool while taking preload readings with the Nm (inch/pound) torque wrench.

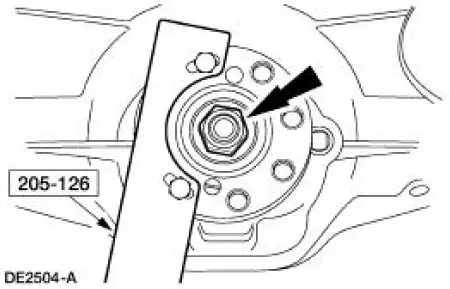

Tighten the nut to set the preload.

- Rotate the drive pinion occasionally to make sure the differential pinion bearings (4630) (4621) seat correctly. Take frequent differential pinion bearing torque preload readings by rotating the drive pinion with a Nm (inch/pound) torque wrench.

- If the preload recorded prior to disassembly is lower than the specification for used bearings, then tighten the nut to specification. If the preload recorded prior to disassembly is higher than the specification for used bearings, then tighten the nut to the original reading as recorded.

- Refer to the torque specification for used differential pinion bearings in the Specifications portion of this section.

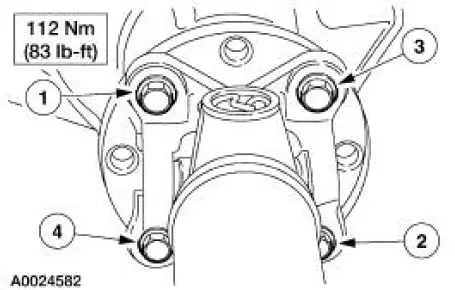

6. CAUTION: Align the index marks.

CAUTION: Install the driveshaft with new bolts. If new bolts are not available, apply Threadlock and Sealer EOAZ-19554-AA or equivalent meeting Ford specification WSKM2G351- A5 to the threads of the original bolts.

CAUTION: The driveshaft centering socket yoke fits tightly on the pinion flange pilot. To make sure that the yoke seats squarely on the flange, tighten the bolts evenly in a cross pattern as shown.

Connect the driveshaft.

7. Install the rear brake calipers.

8. Install the rear wheel and tire assemblies.

9. Lower the vehicle.

Removal

Removal

1. Raise and support the vehicle.

2. Remove the rear wheel and tire assemblies.

3. CAUTION: Remove the rear brake calipers to prevent drag during the

drive pinion

bearing preload adjustment.

CAU ...

Differential Housing Cover

Differential Housing Cover

Removal

1. Raise and support the vehicle.

2. NOTE: Empty the lubricant into a clean container for reuse.

Remove the differential housing cover (4033).

1. Remove the 10 bolts and drain the lubrica ...

Other materials:

Accessory Drive - Cobra

Component Locations -Supercharger Accessory Drive

Component Location -Accessory Drive

...

Connecting Rod - Bearing Journal Clearance

Special Tool(s)

Plastigage

303-D031 (D81L-6002-B) or

equivalent

NOTE: The crankshaft connecting rod journals must be within

specifications to check the connecting

rod bearing journal clearance.

1. Remove the connecting rod bearing cap.

2. ...

Cleaning the windows and wiper blades

The windows and wiper blades should be cleaned regularly. If the wipers

do not wipe properly, substances on the vehicle’s glass or the wiper

blades may be the cause. These may include hot wax treatments used by

commercial car washes, water repellent coatings ...