Ford Mustang (1999-2004) Service Manual: Rear Subframe

Removal and Installation

CAUTION: Suspension fasteners are critical parts because they affect performance of vital components and systems and their failure can result in major service expense. A new part with the same part number must be installed if installation becomes necessary. Torque values must be used as specified during reassembly.

1. Remove the rear coil springs. For additional information, refer to Section.

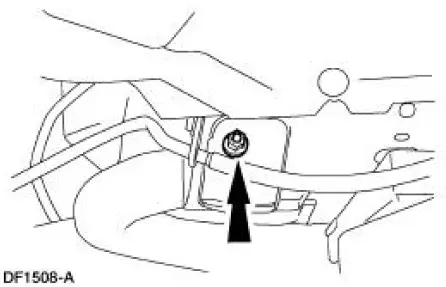

2. Using the special tool, raise the rear subframe.

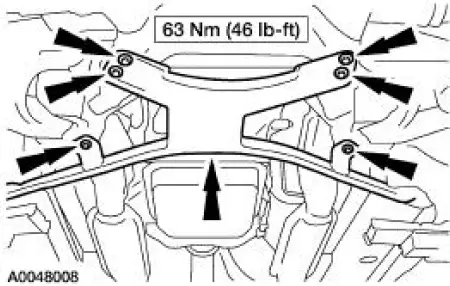

3. Remove and discard the rear subframe front bolts.

4. Using the special tool, lower and remove the rear subframe.

5. NOTE: Discard the old bolts and nuts. Do not reuse, install new bolts and nuts.

To install, reverse the removal procedure.

Subframe Support -Convertible

Removal and Installation

1. Raise and support the vehicle. For additional information, refer to Section.

2. Support the front subframe support.

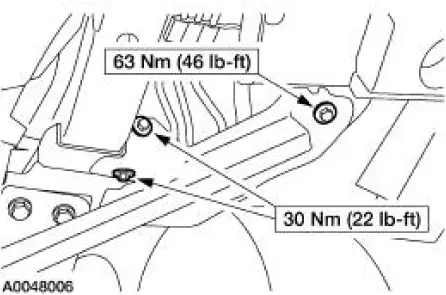

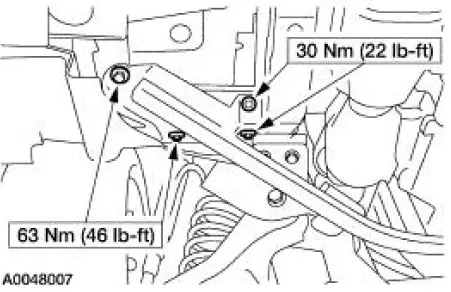

3. Remove the RH front subframe support bolts.

4. Remove the LH front subframe support bolts.

5. Remove the front subframe support.

- Remove the bolts and lower the front subframe support.

6. To install, reverse the removal procedure.

Front Subframe - 4.6L (4V) Engine

Front Subframe - 4.6L (4V) Engine

Special Tool(s)

3-Bar Engine Support Kit

303-F072

Lifting Bracket, Engine

303-D088 (D93P-6001-A2)

Removal and Installation

All vehicles

1. Remove the steering gear. For a ...

General Information

General Information

INTRODUCTION

In the past, when cars were simpler, diagrams were simpler. All components

were connected by wires, and

diagrams seldom exceeded 4 pages in length. Today, some wiring diagrams require

m ...

Other materials:

Four Wheel Anti-Lock Brake System (4WABS) Hydraulic Control Unit (HCU)

NOTE: This procedure only needs to be performed if the 4-wheel

anti-lock brake (4WABS) hydraulic

control unit (HCU) has been installed new or if the HCU lines have been

opened.

1. Clean all dirt from and remove the brake master cylinder filler cap

...

Piston - Ring End Gap

CAUTION: Use care when fitting piston rings to avoid possible damage to

the piston ring

or the cylinder bore.

CAUTION: Piston rings should not be transferred from one piston to another.

NOTE: Cylinder bore must be within specification for taper and

out-of ...

Handle - Exterior Door

Removal

1. Remove the door trim panel (23942). For additional information,

refer to Section.

2. Release the exterior door handle actuating rod by opening the clip.

3. Remove the exterior door handle nuts.

4. Remove the exterior door handle.

Ins ...