Ford Mustang (1999-2004) Service Manual: Removal

CAUTION: Suspension fasteners are critical parts because they affect performance of vital components and systems and their failure can result in major service expense. A new part with the same part number must be installed if installation becomes necessary. If substitution is necessary, the part must be of the same finish and property class. Torque values must be used as specified during reassembly to make sure of correct retention of these parts.

1. Mark the rear shock absorber (18125) relative to the protective sleeve with the vehicle in a static, level ground position (curb height).

2. Raise the vehicle on a hoist. .

3. Remove both wheel and tire assemblies.

4. Remove the rear brake disc.

5. Remove the rear springs (5560). For additional information, refer to Spring-Cobra in this section.

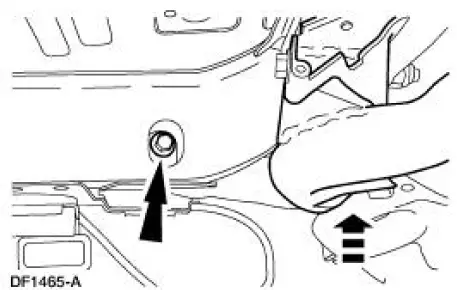

6. Raise the subframe into position and remove the front bolts.

7. Lower the subframe from the vehicle.

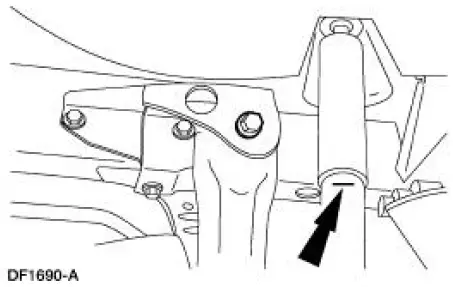

8. Mark the cam bolt position relative to the upper suspension arm and bushing (5500).

9. NOTE: Mark a new cam bolt in the same position as the old one for assembly reference before discarding the old bolt.

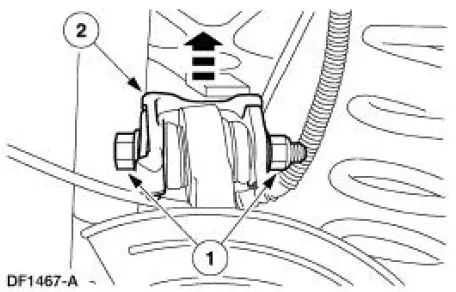

Disconnect the upper suspension arm and bushing from the knuckle (5A968/5A969).

1. Remove and discard the nut and bolt.

2. Disconnect the upper suspension arm and bushing.

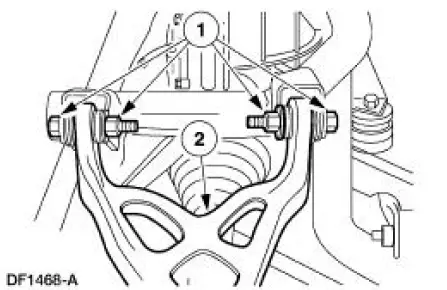

10. Remove the upper suspension arm and bushing.

1. Remove and discard the nuts and bolts.

2. Remove the upper suspension arm and bushing.

Installation

Installation

CAUTION: The upper suspension arm and bushing nuts must be tightened

with the

suspension at curb height. Failure to do so can result in bushing failure,

resulting in poor ride

and handling.

NOTE: If ...

Other materials:

Electronic Engine Controls (Description and Operation)

The electronic engine controls consist of the following:

powertrain control module (PCM)

throttle position (TP) sensor

idle air control (IAC) valve

engine coolant temperature (ECT) sensor

cylinder head temperature sensor

camshaft position ...

Ignition switch

A. Off: The ignition is off.

Note: When you switch the ignition off and leave your vehicle, do not

leave your key in the ignition. This could cause your vehicle battery to

lose charge.

B. Accessory: Allows the electrical accessories such as the radio to

ope ...

Assembly

1. NOTE: Universal joint kits are to be installed as complete

assemblies only. Do not mix

components from other U-joint kits.

Install the spider.

1. Start a new bearing cup into the driveshaft yoke.

Check the needle bearings for correct positioning.

...