Ford Mustang (1999-2004) Service Manual: Installation

CAUTION: The upper suspension arm and bushing nuts must be tightened with the suspension at curb height. Failure to do so can result in bushing failure, resulting in poor ride and handling.

NOTE: If installing a new upper suspension arm and bushing, mark the cam bolt side of the new arm in the same position as the old arm for assembly reference.

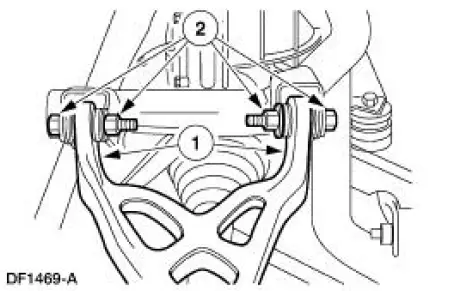

1. Install the upper suspension arm and bushing.

1. Position the arm and bushing on the subframe.

2. Install new bolts and nuts. Do not tighten the nuts at this time.

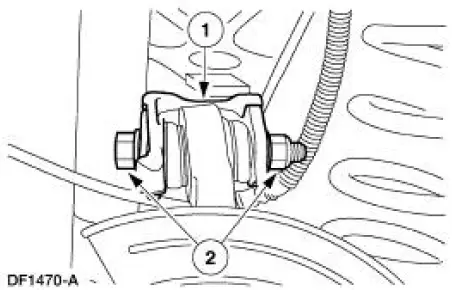

2. Connect the upper suspension arm and bushing to the knuckle.

1. Position the arm and bushing.

2. Install a new cam bolt and a new nut. Do not tighten the nut at this time.

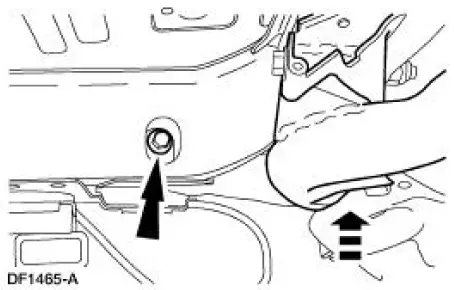

3. Raise the subframe into position and install new front bolts.

4. Install the springs. For additional information, refer to Spring-Cobra in this section.

5. Position a jack stand under the lower suspension arm and bushing.

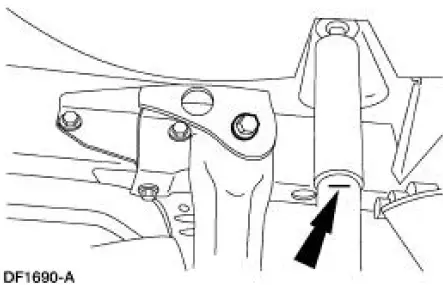

6. Raise the suspension until the shock absorber is compressed to the alignment mark (curb height).

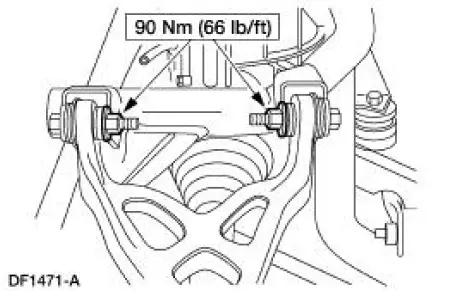

7. Tighten the nuts.

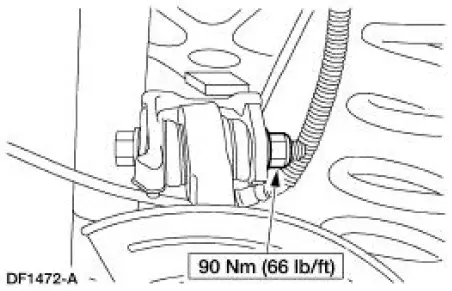

8. Position the cam bolt so the marks are aligned. Tighten the nut.

9. Lower the suspension and remove the jack stand.

10. Install the rear brake disc.

11. Install the wheel and tire assembly.

12. Lower the vehicle.

13. Check wheel alignment, adjust if necessary.

Removal

Removal

CAUTION: Suspension fasteners are critical parts because they affect

performance of vital

components and systems and their failure can result in major service expense. A

new part with

the same part ...

Lower Arm

Lower Arm

Removal

CAUTION: Suspension fasteners are critical parts because they affect

performance of vital

components and systems and their failure can result in major service expense. A

new part with

the sa ...

Other materials:

SecuriLock® passive anti-theft system

Note: The system is not compatible with non-Ford aftermarket remote

start systems. Use of these systems may result in vehicle starting

problems and a loss of security protection.

Note: Metallic objects, electronic devices or a second coded key on the

same key ...

Torque Converter (Description and Operation)

The torque converter transmits and multiplies torque. The torque

converter is a four-element device:

impeller assembly

turbine assembly

reactor assembly

clutch and damper assembly

The standard torque converter components operate as follo ...

Pump and Intermediate Clutch Piston

Special Tool(s)

Installer, Front Pump Fluid

Seal

307-014 (T63L-77837-A)

Protector, Piston Seal

307-339 (T95L-77005-A)

Pump and Intermediate Clutch Piston - Disassembled View

...