Ford Mustang (1999-2004) Service Manual: Removal

1. Remove the differential housing cover (4033) and drain the rear axle (4001). For additional information, refer to Differential Housing Cover in this section.

2. CAUTION: Reinstall the differential pinion shaft (4211) and the bolt in the differential case (4204) after removing the axle shafts (4234).

Remove the axle shafts. For additional information, refer to Axle Shaft in this section.

3. Wipe the lubricant from the internal working parts and inspect the parts for wear and damage.

4. Rotate the differential assembly to check for roughness indicating bearing/gear damage.

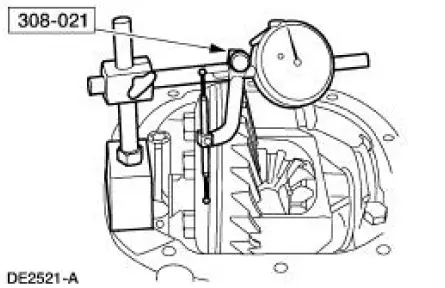

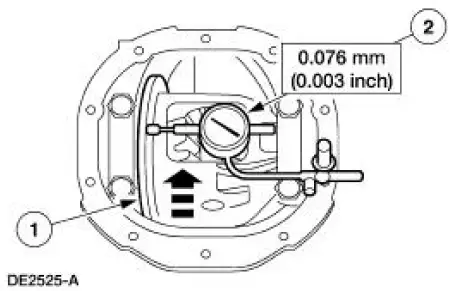

5. Using a suitable dial indicator and the special tool, measure and note the ring gear backface runout.

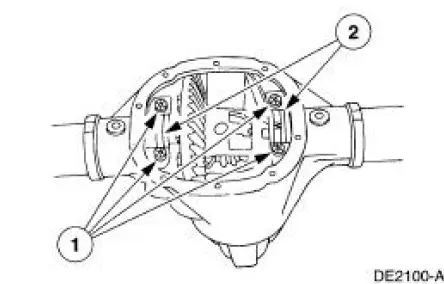

6. CAUTION: Mark the position and location of the bearing caps, as the arrows may not be visible. Always install the bearing caps in their identical locations and positions.

Remove the bearing caps.

1. Remove the bolts.

2. Remove the bearing caps.

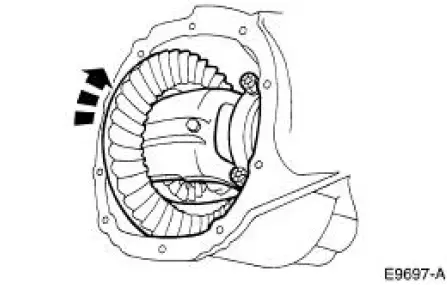

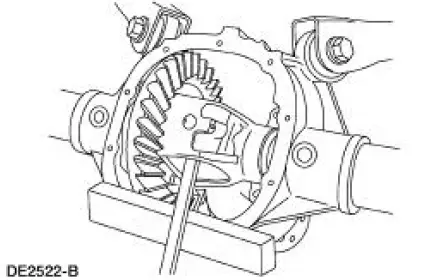

7. WARNING: Do not allow the differential assembly to fall. Failure to follow these instructions may result in personal injury and component damage.

CAUTION: Place a wood block between the pry bar and the differential housing 4010) to protect the machined surface from damage.

Using a pry bar and a wood block, remove the differential assembly from the differential housing.

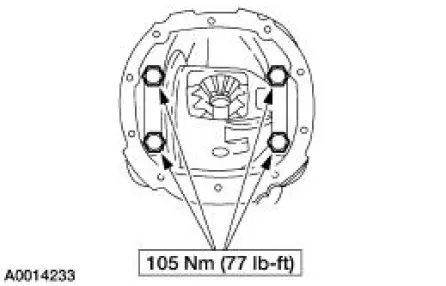

8. Remove the 10 bolts.

9. CAUTION: Do not damage the threads in the bolt holes.

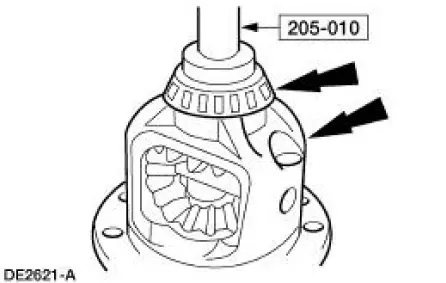

Insert a punch in the bolt holes, and drive off the ring gear.

10. If the ring gear backface runout measurement, taken at the beginning of this procedure, did not exceed the specification, proceed to the appropriate procedure as necessary: Drive Pinion , Differential Case and Ring Gear-Conventional or Differential Case and Ring Gear-Traction- Lok in this section, or to Installation in this procedure. If the ring gear backface runout measurement, taken at the beginning of this procedure, exceeded the specification, the cause may be a warped ring gear, differential case/differential bearing damage. Proceed as follows to verify the cause of the excessive runout.

11. Position the differential assembly, including the differential bearing cups (4222) and differential bearing shims (4067), in the differential housing. Install the bearing caps and bolts.

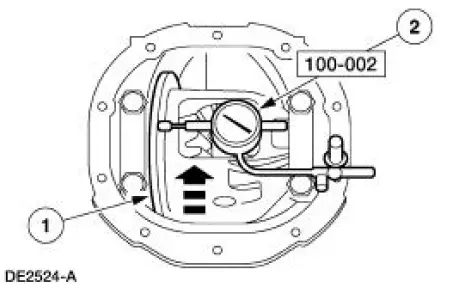

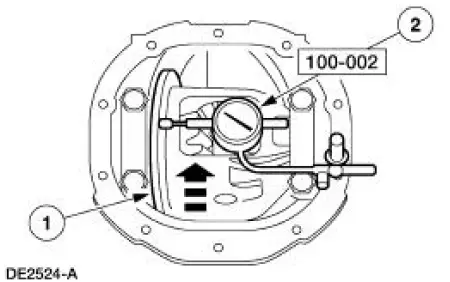

12. Position the special tool.

1. Rotate the differential case to verify that the differential bearings (4221) have seated correctly.

2. Position the special tool.

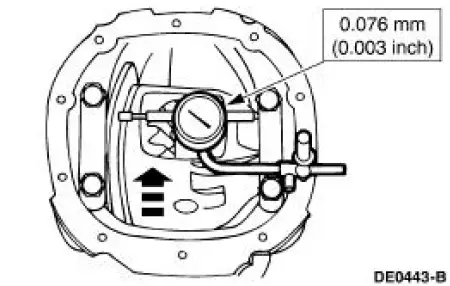

13. Measure and note the differential case runout.

1. Rotate the differential case.

2. Note the runout.

- If the runout does not exceed the specification, install a new ring gear and drive pinion gear. For additional information, refer to Drive Pinion in this section and to Installation in this procedure.

- If the runout exceeds the specification, the ring gear is true and the concern is due to either differential case/differential bearing damage. Proceed as follows.

14. Remove the differential assembly from the differential housing.

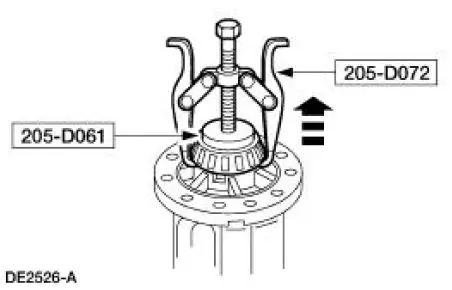

15. Using the special tools, remove the differential bearings.

16. Using the special tool, install the new differential bearings.

17. Position the differential assembly, including the differential bearing cups and differential bearing shims, in the differential housing. Install the bearing caps and bolts.

18. Position the special tool.

1. Rotate the differential case to verify that the differential bearings have seated correctly.

2. Position the special tool.

19. Measure the differential case runout.

- If the runout does not exceed the specification, use the new differential bearings for assembly.

- If the runout exceeds the specification, install a new differential case. For additional information, refer to Differential Case and Ring Gear-Conventional or Differential Case and Ring Gear-Traction-Lok in this section.

20. Remove the differential assembly from the differential housing.

Differential Case

Differential Case

Special Tool(s)

2-Jaw Puller

205-D072 (D97L-4221-A) or

equivalent

Dial Indicator Gauge with

Holding Fixture

100-002 (TOOL-4201-C) or

equivalent

Gauge, Clutch Hou ...

Installation

Installation

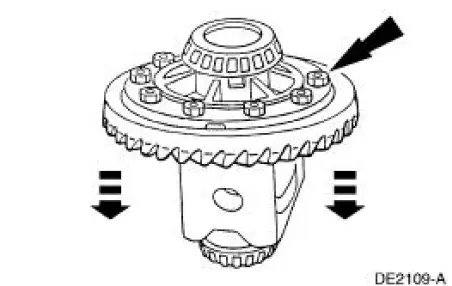

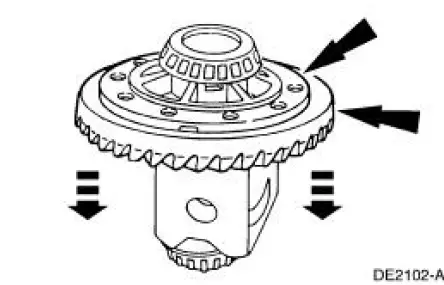

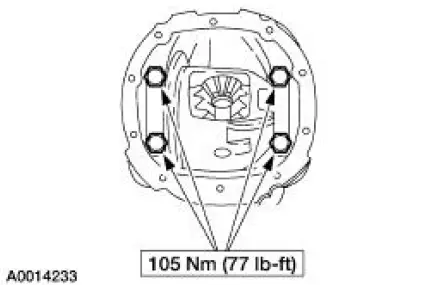

All axles

1. Position the ring gear and the differential case. Align the bolt holes by

starting two bolts through

the holes in the differential case and the ring gear. Press the ring gear on the

dif ...

Other materials:

Transmission (INSTALLATION)

Special Tool(s)

Retainer, Torque Converter

307-346 (T97T-7902-A)

Material

Item

Specification

Multi-Purpose Grease

D0AZ-19584-AA

ESB-M1C93-

B

MERCON V Automatic

Transmission Fluid

XT-5-QM, XT-5-DM

MERCON V

1. CA ...

Torque Converter (Description and Operation)

The torque converter transmits and multiplies torque. The torque

converter is a four-element device:

impeller assembly

turbine assembly

reactor assembly

clutch and damper assembly

The standard torque converter components operate as follo ...

Striker Adjustment

NOTE: After adjusting the door latch striker plate, verify that the

door can be closed easily and fits

tightly.

1. Loosen the door latch striker plate bolts.

2. Reposition the door latch striker plate from side to side or up and down

as necessary.

...