Ford Mustang (1999-2004) Service Manual: Spring Lock Coupling

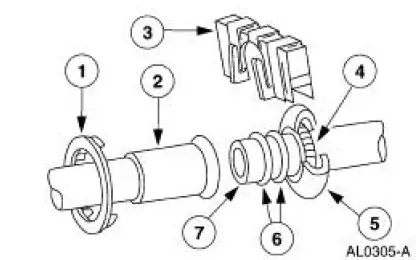

The spring lock coupling is a refrigerant line coupling held together by a garter spring inside a circular cage.

- When the coupling is connected together, the flared end of the female fitting slips behind the garter spring inside the cage of the male fitting.

- The garter spring and cage then prevent the flared end of the female fitting from pulling out of the cage.

- Three O-ring seals are used to seal between the two halves of the A/C condenser core couplings. All other couplings have two O-ring seals.

- Use only the O-ring seals listed in the Ford Master Parts Catalog for the spring lock coupling.

- A plastic indicator ring is used on the spring lock couplings of the A/C evaporator core to indicate, during vehicle assembly, that the coupling is connected. Once the coupling is connected, the indicator ring is no longer necessary but will remain captive by the coupling near the cage opening.

- The indicator ring may also be used during repair operations to indicate connection of the coupling.

- An A/C tube lock coupling clip (19E746) may be used to secure the coupling but is not required.

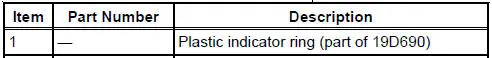

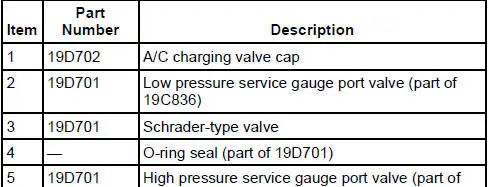

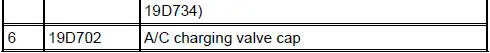

Service Gauge Port Valves

The high-pressure service gauge port valve is located on the A/C manifold and tube.

The low pressure service gauge port valve is located on the suction accumulator.

The fitting is an integral part of the refrigeration line or component.

- Special couplings are required for both the high side and low side service gauge ports.

- A new Schrader-type valve core can be installed if the seal leaks.

- Always install the A/C charging valve cap (19D702) on the service gauge port valves after repairing the refrigerant system.

Dual-Function Pressure Switch (4.6L)

Dual-Function Pressure Switch (4.6L)

The dual-function pressure switch is used to interrupt A/C compressor

operation in the event of high system discharge pressures.

The dual-function pressure switch is mounted on a Schrader valve-t ...

Air Conditioning (A/C) Compressor - 3.8L

Air Conditioning (A/C) Compressor - 3.8L

Material

Item

Specification

PAG Refrigerant Compressor

Oil (R-134a Systems)

F7AZ-19589-DA (Motorcraft YN-

12-C)

WSH-M1C231-

B

Removal and Installation

CAUTION: If installing ...

Other materials:

Bushing - Stabilizer Bar

Removal

CAUTION: Suspension fasteners are critical parts because they affect

performance of vital

components and systems and their failure can result in major service expense. A

new part with

the same part number or an equivalent part must be installed, if i ...

Cleaning the exterior

Wash your vehicle regularly with cool or lukewarm water and a neutral

pH shampoo, such as Motorcraft® Detail Wash.

• Do not use a commercial or high-pressure wand on the surface or

edge of stripes and graphics. This can cause damage to the film and

cause th ...

Steering System (Diagnosis and Testing)

Special Tool(s)

Dial Thermometer 0-220F

023-R0007 or Equivalent

Hand Held Automotive Meter

105-R0053 or Equivalent

Power Steering Analyzer

211-F001 (014-00207) or

Equivalent

Spring Scale

211-034 (T74P-3504-Y)

...