Ford Mustang (1999-2004) Service Manual: Stabilizer Bar

Removal

CAUTION: Suspension fasteners are critical parts because they affect performance of vital components and systems and their failure can result in major service expense. A new part with the same part number must be installed if installation becomes necessary. If substitution is necessary, the part must be of the same finish and property class. Torque values must be used as specified during reassembly to make sure of correct retention of these parts.

1. Raise the vehicle.

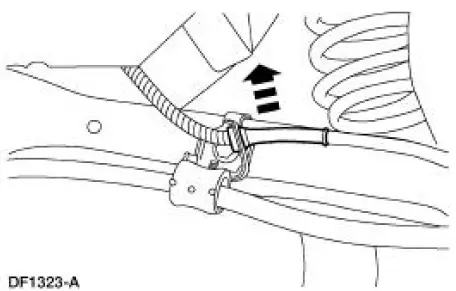

2. Disconnect the anti-lock brake sensor wires from the brackets.

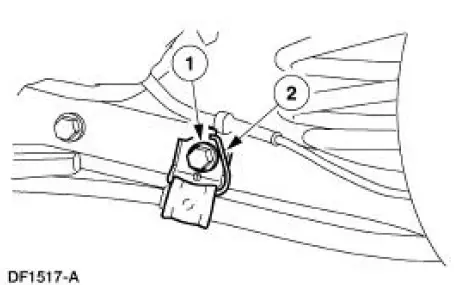

3. Remove the parking brake cable brackets.

1. Remove and discard the bolts.

2. Remove the parking brake cable brackets.

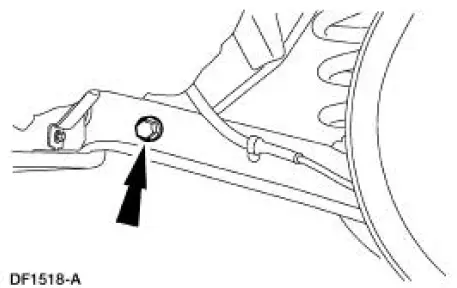

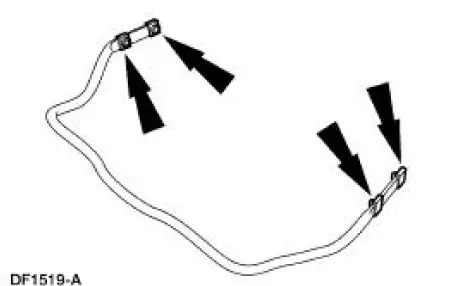

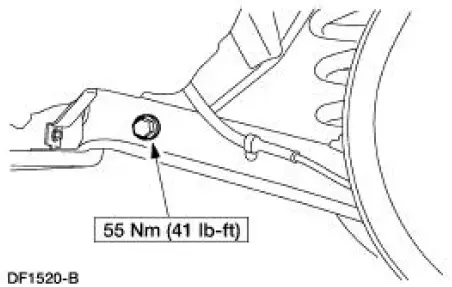

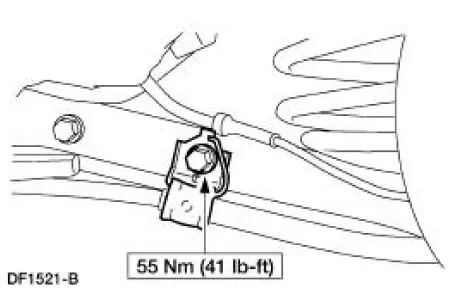

4. Remove the bolts and the stabilizer bar (5A772). Discard the bolts.

5. Remove and discard the nuts from the stabilizer bar.

Installation

NOTE: Make sure the rear stabilizer bar is not installed upside down. A color code is provided on the right (passenger) side only as an aid for correct positioning.

NOTE: Use new fasteners when installing the stabilizer bar.

1. To install, reverse the removal procedure.

Lower Arm

Lower Arm

Removal

CAUTION: Suspension fasteners are critical parts because they affect

performance of vital

components and systems and their failure can result in major service expense. A

new part with

the sa ...

Stabilizer Bar - Cobra

Stabilizer Bar - Cobra

Removal

CAUTION: Suspension fasteners are critical parts because they affect

performance of vital

components and systems and their failure can result in major service expense. A

new part with

the sa ...

Other materials:

Actuator Cable - Speed Control

1. Remove the speed control actuator cable end from the throttle body.

1. Lift the speed control cable from the throttle nailhead.

2. Release the speed control cable from the throttle bracket.

2. Remove the speed control cable from the retaining cli ...

Rear View Mirrors

Torque Specifications

Rear View Mirrors

The rear view mirror system consists of the following components:

exterior rear view mirror

exterior rear view mirror control

exterior rear view mirror glass

exterior rear view mirror motor

interior ...

Engine (Removal)

Special Tool(s)

Special Tool(s)

Support Bracket, Engine

303-639

Spreader Bar

303-D089 (D93P-6001-A3)

Lifting Bracket Set, Engine

303-D074 (D91P-6001-A)

Removal

1. Remove the hood.

2. Remove the battery. For additi ...