Ford Mustang (1999-2004) Service Manual: Throttle Body

Removal

WARNING: Do not smoke or carry lighted tobacco or open flame of any type when working on or near any fuel related components. Highly flammable mixtures are always present and may be ignited. Failure to follow these instructions may result in personal injury.

CAUTION: The throttle body bore and plate area have a special coating and cannot be cleaned.

1. Remove the air cleaner outlet tube (9B659). For additional information, refer to Section.

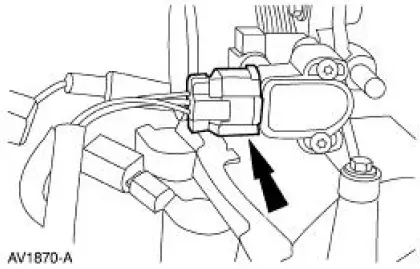

2. Disconnect the throttle position (TP) sensor electrical connector.

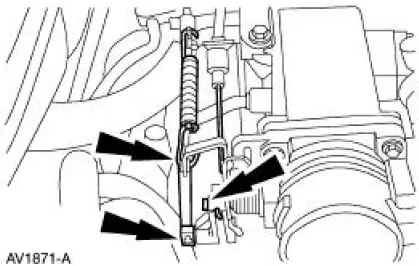

3. Disconnect the accelerator controls.

- Disconnect the accelerator cable (9E926).

- Disconnect the speed control cable (9A825).

- Disconnect the return spring.

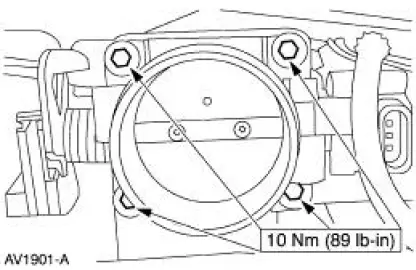

4. NOTE: Discard the throttle body gasket.

Remove the throttle body.

- Remove the bolts.

- Remove the throttle body.

Installation

1. To install, reverse the removal procedure.

Fuel Charging And Controls

Fuel Charging And Controls

The fuel injection supply manifold (9F792):

delivers fuel to the fuel injector.

receives fuel from the fuel supply line.

The throttle body (9E926):

controls air supply to the upper intake manifo ...

Fuel Injectors

Fuel Injectors

Removal

WARNING: Do not smoke or carry lighted tobacco or open flame of any

type when

working on or near any fuel related components. Highly flammable mixtures are

always present

and may be ignited. ...

Other materials:

Air Cleaner - 4.6L (2V) and 4.6L (4V)

Removal and Installation

Mach I

1. Disconnect the air intake scoop outlet tube.

All vehicles

2. Remove the air cleaner outlet tube from the throttle body. For

additional information, refer to Air

Cleaner Outlet Pipe-4.6L (2V) or Air Cleaner Outlet Pipe- ...

Disassembly

1. Remove the retaining ring above fifth gear.

2. CAUTION: Hand tighten the special tool to prevent gear damage.

CAUTION: Support the output shaft while using the press to prevent

damage to the

shaft or gears.

Using the special tool, press fifth gear, the s ...

Suction Accumulator

NOTE: Installation of a new suction accumulator is not required when

repairing the air conditioning

system except when there is physical evidence of contamination from a failed A/C

compressor or

damage to the suction accumulator.

In addition to th ...