Ford Mustang (1999-2004) Service Manual: Suction Accumulator

NOTE: Installation of a new suction accumulator is not required when repairing the air conditioning system except when there is physical evidence of contamination from a failed A/C compressor or damage to the suction accumulator.

In addition to the preceding condition, a new suction accumulator should be installed if one of the following conditions exist:

- The suction accumulator is perforated.

- The refrigerant system has been opened to the atmosphere for a period of time longer than required to make a minor repair.

- There is evidence of moisture in the system such as internal corrosion of metal refrigerant lines or the refrigerant oil is thick and dark.

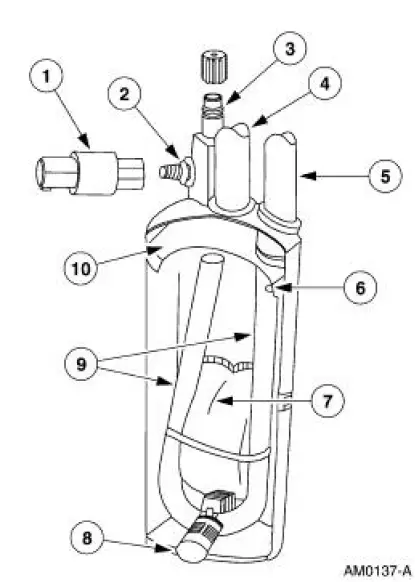

The suction accumulator (19C836) is mounted to the A/C accumulator bracket (19D606) to the right of the vehicle centerline. The inlet tube of the suction accumulator attaches directly to the A/C evaporator core outlet tube and the outlet tube attaches to the A/C manifold and tube.

After entering the inlet of the suction accumulator, the heavier oil-laden refrigerant contacts an internally mounted dome (which serves as an umbrella) and drips down onto the bottom of the canister.

- A small diameter oil bleed hole, in the bottom of the vapor return tube, allows the accumulated heavier liquid refrigerant and oil mixture to reenter the compressor suction line at a controlled rate.

- As the heavier mixture passes through the small diameter liquid bleed hole, it has a second chance to vaporize and recirculate through the A/C compressor without causing compressor damage due to slugging.

- A fine mesh screened filter fits tightly around the bottom of the vapor return tube to filter out refrigerant system contaminant particles.

- A desiccant bag is mounted inside the canister to absorb any moisture which may be in the refrigerant system.

- A fitting located on the top of the suction accumulator is used to attach the A/C cycling switch. A long-travel Schrader-type valve stem core is installed in the fitting so that the A/C cycling switch can be removed without discharging the A/C system.

A/C Cycling Switch

The A/C cycling switch is mounted on a Schrader-type valve fitting on the top of the suction accumulator.

- A valve depressor, located inside the threaded end of the A/C cycling switch, presses in on the Schrader valve stem.

- This allows the suction pressure inside the suction accumulator to control the operation of the A/C cycling switch.

- The electrical switch contacts open when the suction pressure drops. The contacts close when the suction pressure rises. For specifications regarding operating pressure(s), refer to Section.

- The A/C cycling switch will control the A/C evaporator core pressure at a point where the plate/fin surface temperature will be maintained slightly above freezing.

- This prevents icing of the A/C evaporator core and blockage of air flow.

- It is not necessary to discharge the refrigerant system to remove the A/C cycling switch.

Evaporator Core Orifice

Evaporator Core Orifice

NOTE: The evaporator core orifice is an integral part of the condenser

to evaporator line and should

be installed as an assembly with the line.

NOTE: A new evaporator core orifice should be instal ...

Dual-Function Pressure Switch (4.6L)

Dual-Function Pressure Switch (4.6L)

The dual-function pressure switch is used to interrupt A/C compressor

operation in the event of high system discharge pressures.

The dual-function pressure switch is mounted on a Schrader valve-t ...

Other materials:

Installation

All axles

1. Position the ring gear and the differential case. Align the bolt holes by

starting two bolts through

the holes in the differential case and the ring gear. Press the ring gear on the

differential case.

2. Install the bolts.

Apply Stud and Bea ...

Inspection and Verification

1. Verify the customer concern is with the evaporative emission (EVAP)

system.

2. Visually inspect for the following obvious signs of mechanical damage.

Visual Inspection Chart

Mechanical

Fuel filler cap

EVAP test port

...

Child Safety

GENERAL INFORMATION

See the following sections for directions on how to properly use safety

restraints for children.

WARNING: Always make sure your child is secured properly in

a device that is appropriate for their height, age and weight.

Child safety restra ...