Ford Mustang (1999-2004) Service Manual: Throttle Position (TP) Sensor

Removal

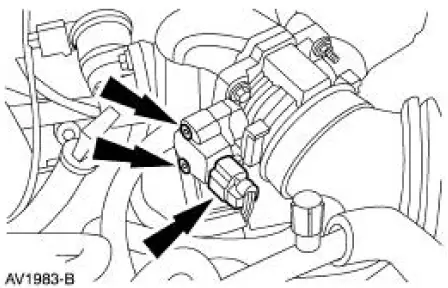

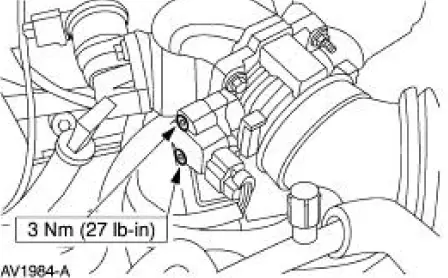

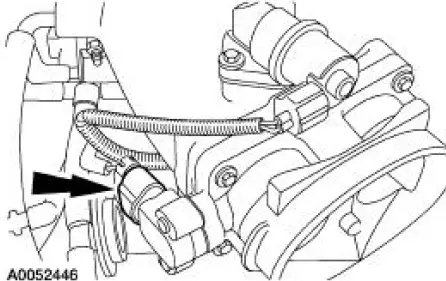

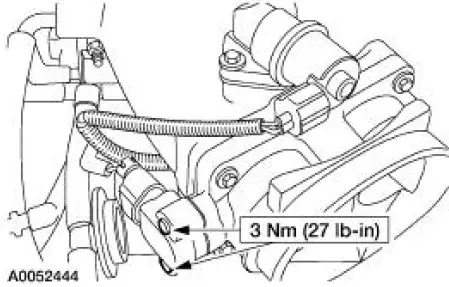

NOTE: The 3.8L engine is shown; the 4.6L (2V) is similar.

1. Disconnect the battery ground cable. For additional information, refer to Section.

2. Remove the throttle position (TP) sensor.

- Disconnect the connector.

- Remove the screws, and remove the sensor.

Installation

1. To install, reverse the removal procedure.

Throttle Position (TP) Sensor -Cobra

Removal and Installation

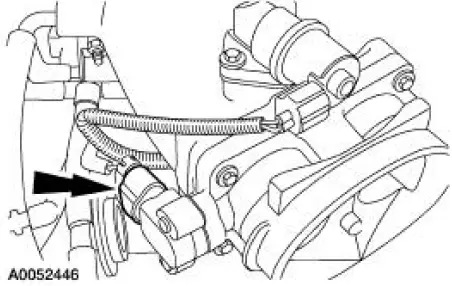

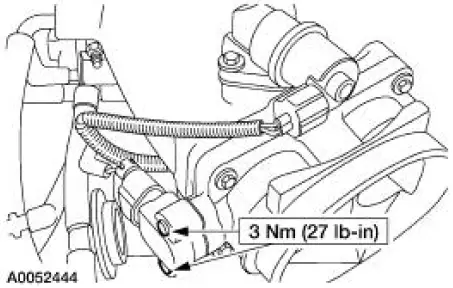

1. Disconnect the throttle position (TP) sensor electrical connector.

2. Remove the bolts and the TP sensor.

3. To install, reverse the removal procedure.

Throttle Position (TP) Sensor -Mach I

Removal and Installation

1. Remove the air intake scoop bracket. For additional information, refer to Section.

2. Disconnect the throttle position (TP) sensor electrical connector.

3. Remove the bolts and the TP sensor.

4. To install, reverse the removal procedure.

Powertrain Control Module (PCM)

Powertrain Control Module (PCM)

Removal

1. Disconnect the battery ground cable. For additional information,

refer to Section.

2. Remove the RH front door scuff plate.

3. Remove the RH cowl side trim panel.

Remove the ...

Idle Air Control (IAC) Valve - 3.8L

Idle Air Control (IAC) Valve - 3.8L

Removal

1. Disconnect the battery ground cable. For additional information,

refer to Section.

2. NOTE: Discard the idle air control (IAC) valve gasket.

Remove the IAC valve.

Disconnec ...

Other materials:

Pinpoint Tests

The pinpoint tests are a step-by-step diagnostic process designed to

determine the cause of a condition. It may not always be necessary to follow a

pinpoint test to its conclusion. Carry out only the

steps necessary to correct the condition. Then, test the s ...

Principles of Operation

NOTE: A new instrument cluster must be reconfigured. Refer to

Section.

The instrument cluster is a hybrid electronic cluster (HEC). The

instrument cluster uses both hardwired

and the standard corporate protocol (SCP) communication network to transmit

a ...

Removal

Automatic transmission vehicles

1. Remove the flexplate. For additional information, refer to Flexplate in

this section.

Manual transmission vehicles

2. Remove the flywheel. For additional information, refer to Flywheel in this

section.

All vehicles

3. Using ...