Ford Mustang (1999-2004) Service Manual: Electronic Engine Controls

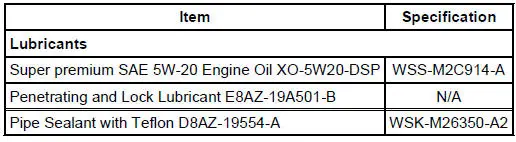

General Specifications

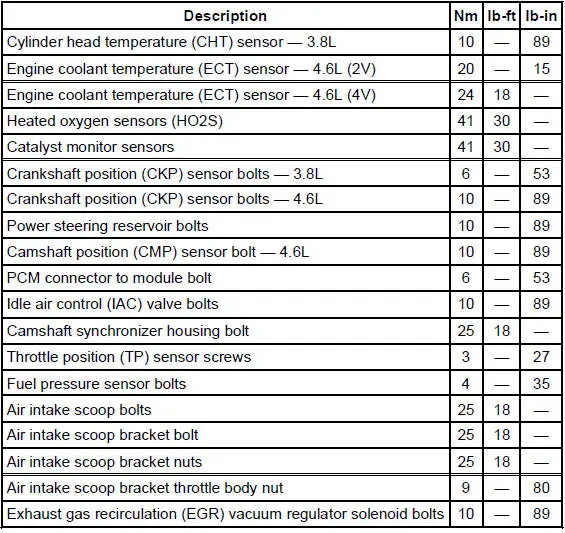

Torque Specifications

- Electronic Engine Controls (Description and Operation)

- Electronic Engine Controls - Cobra

- Temperature and Manifold Absolute Pressure (T-MAP) Sensor - Cobra

- Camshaft Position (CMP) Sensor - 3.8L

- Camshaft Position (CMP) Sensor - 4.6L

- Intake Manifold Runner Control (IMRC) Actuator - 3.8L

- Crankshaft Position (CKP) Sensor - 3.8L

- Crankshaft Position (CKP) Sensor - 4.6L

- Powertrain Control Module (PCM)

- Throttle Position (TP) Sensor

- Idle Air Control (IAC) Valve - 3.8L

- Idle Air Control (IAC) Valve - 4.6L (2V)

- Idle Air Control (IAC) Valve - Cobra

- Idle Air Control (IAC) Valve - Mach I

- Cylinder Head Temperature (CHT) Sensor - 3.8L

- Engine Coolant Temperature (ECT) Sensor - 4.6L (2V)

- Engine Coolant Temperature (ECT) Sensor - Cobra

- Engine Coolant Temperature (ECT) Sensor - Mach I

- Mass Air Flow (MAF) Sensor - 3.8L

- Mass Air Flow (MAF) Sensor - 4.6L (2V)

- Mass Air Flow (MAF) Sensor - Cobra

- Mass Air Flow (MAF) Sensor - Mach I

- Heated Oxygen Sensor (HO2S)

- Catalyst Monitor Sensor

- Clutch Pedal Position (CPP) Switch

- Fuel Pressure Sensor

- Supercharger Bypass Vacuum Solenoid - Actuator

Evaporative Emission Test Port

Evaporative Emission Test Port

Removal and Installation

1. Disconnect the pin-type retainer.

2. Raise and support the vehicle. For additional information, refer to

Section.

3. Remove the RH front wheel. For additional informa ...

Electronic Engine Controls (Description and Operation)

Electronic Engine Controls (Description and Operation)

The electronic engine controls consist of the following:

powertrain control module (PCM)

throttle position (TP) sensor

idle air control (IAC) valve

engine coolant temperature (ECT) sens ...

Other materials:

Camshaft End Play - Push Rod Engines

Special Tool(s)

Dial Indicator Gauge with

Holding Fixture

100-002 (TOOL-4201-C) or

equivalent

1. Remove the valve tappets. Refer to the appropriate section in Group 303

for the procedure.

2. Use a Dial Indicator Gauge with Holding Fixture ...

Exhaust System (Description and Operation)

WARNING: The normal operating temperature of the exhaust system is very

high. Never

attempt to repair any part of the system until it has cooled. Be especially

careful when working

around the three way catalytic converter. The temperature of the three way

c ...

Principles of Operation

Evaporative Emission (EVAP) Canister Purge Valve

The EVAP canister purge valve is controlled by the powertrain control

module (PCM). The EVAP

canister purge valve controls the flow of fuel vapors from the EVAP canister

to the engine intake

manifold duri ...