Ford Mustang (1999-2004) Service Manual: Wheel Hub or Axle Flange Bolt Circle Runout

NOTE: The brake discs must be removed to carry out all runout measurements.

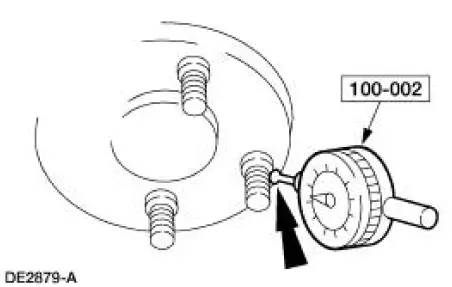

1. Position the special tool perpendicular to the wheel hub or axle flange bolt, as close to the hub or flange face as possible. Zero the indicator to allow the pointer to deflect either way.

2. Rotate the hub or flange until the next bolt is contacted. Record the measurement and continue until each bolt is checked. The difference between the maximum and minimum contact readings will be the total wheel hub or axle flange bolt pattern runout. The runout must not exceed 0.38 mm (0.015 inch).

Pilot Runout

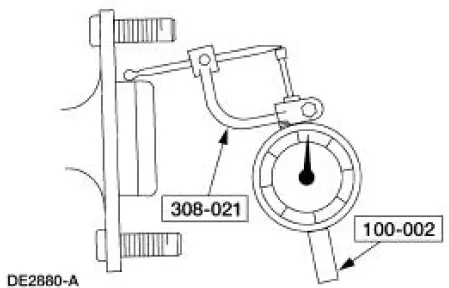

1. Position the special tools as close to the hub or axle flange face as possible. Zero the indicator to allow the pointer to deflect either way.

2. Rotate the hub or flange one full turn and note the maximum and minimum readings. The difference between the maximum and minimum readings will be the total pilot runout. Pilot runout must not exceed 0.15 mm (0.006 inch).

Driveline Angle

Driveline Angle

Item

Description

1

Bottom of the frame

2

Engine crankshaft centerline

3

Engine angle

4

Driveshaft and coupling shaft centerline

5

Driveshaft an ...

Wheel Hub or Axle Flange Face Runout

Wheel Hub or Axle Flange Face Runout

NOTE: If the axle shaft assembly is removed, check runout of the shaft

itself. The forged (unmachined)

part of the shaft is allowed to have as much as 3.0 mm (0.120 inch) runout. This

alone will not ...

Other materials:

Transmission (Assembly)

Special Tool(s)

Dial Indicator Gauge with

Holding Fixture

100-002 (TOOL-4201-C) or

equivalent

Holding Fixture, Transmission

307-003 (T57L-500-B)

Remover/Installer, Bearing

Tube

308-024 (T75L-7025-B)

Re ...

Electronic Pressure Control (EPC) Solenoid

Special Tool(s)

Gauge, Transmission Solenoid

Connectors

307-426

Removal

1. Remove the manual control lever. For additional information, refer to

Manual Control Lever

Shaft and Seal in this section.

2. CAUTION: Do not pull on the molded ...

Reverse Sun Gear

Disassembly

1. Remove the reverse clutch sun gear assembly and the No. 4 forward clutch

hub bearing and

race.

2. Remove the forward clutch sun gear assembly and the No. 5 forward clutch

sun gear bearing

and race.

Assembly

1. The forward clutch ...