Ford Mustang (1999-2004) Service Manual: Driveline Angle

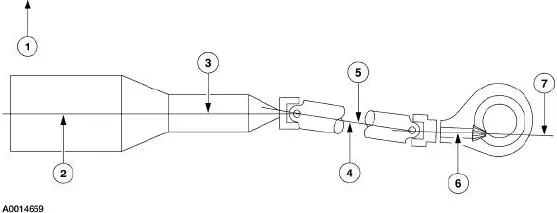

| Item | Description |

| 1 | Bottom of the frame |

| 2 | Engine crankshaft centerline |

| 3 | Engine angle |

| 4 | Driveshaft and coupling shaft centerline |

| 5 | Driveshaft and coupling shaft angle |

| 6 | Rear axle pinion centerline |

| 7 | Axle pinion angle |

An incorrect driveline (pinion) angle can often be detected by the driving condition in which the vibration occurs.

- A vibration during coastdown from 72 to 56 km/h (45 to 35 mph) is often caused by an excessive U-joint angle at the axle (pinion nose downward).

- A vibration during acceleration, from 56 to 72 km/h (35 to 45 mph) may indicate an excessive Ujoint angle at the axle (pinion nose upward).

When these conditions exist, check the driveline angles as described in the General Procedures portion of this section.

If the tires and driveline angle are not the cause, carry out the NVH tests to determine whether the concern is caused by a condition in the axle.

Universal Joint (U-Joint) Wear

Place the vehicle on a frame hoist and rotate the driveshaft by hand. Check for rough operation or seized U-joints. Install a new U-joint if it shows signs of seizure, excessive wear, or incorrect seating.

Analysis of Vibration

Analysis of Vibration

WARNING: A vehicle equipped with a Traction-Lok differential will

always have both

wheels driving. If only one wheel is raised off the floor and the rear axle is

driven by the engine,

the wheel on t ...

Wheel Hub or Axle Flange Bolt Circle Runout

Wheel Hub or Axle Flange Bolt Circle Runout

NOTE: The brake discs must be removed to carry out all runout

measurements.

1. Position the special tool perpendicular to the wheel hub or axle flange bolt,

as close to the hub

or flange face as po ...

Other materials:

Removal

WARNING: Always wear safety glasses when repairing an air bag

supplemental restraint

system (SRS) vehicle and when handling an air bag module. This will

reduce the risk of injury

in the event of an accidental deployment.

WARNING: Carry a live air ...

Transmission fluid check

Checking Automatic Transmission Fluid

Note: Transmission fluid should be checked and, if required, added by

an authorized dealer.

The automatic transmission does not have a transmission fluid dipstick.

See your Scheduled Maintenance Information for scheduled ...

Assembly

1. Install the new O-ring.

2. Assemble the gear shifter forks.

1. Install the gear shift plate into the gear shifter fork.

2. Install the gear shift fork inserts.

3. NOTE: Position the narrow side of the C-shaped gear selector

interlock sleeve in ...