Ford Mustang (1999-2004) Service Manual: Wiper Blade and Pivot Arm Adjustment

1. Cycle and park the windshield wipers.

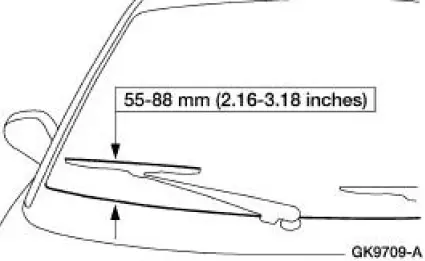

2. Verify that the distance between the center of the RH windshield wiper blade and the top edge of the cowl top vent panel is within specification.

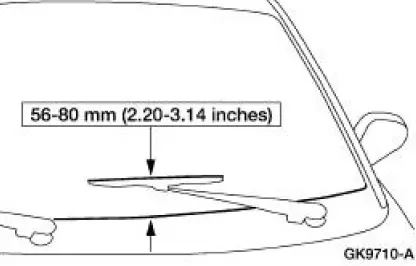

3. Verify that the distance between the center of the LH windshield wiper blade and the top edge of the cowl top vent panel is within specification.

4. If the distance is not within specification, remove the windshield wiper pivot arms and reposition to specification.

Remove the pivot arm.

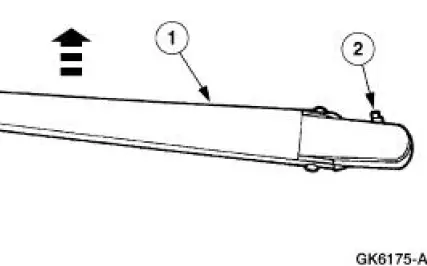

1. Pull up on the pivot arm.

2. Pull out on the retainer tab and remove the pivot arm.

Pivot Arm

Removal

1. NOTE: New windshield wiper pivot arms need to be installed as an assembly.

Remove the pivot arm.

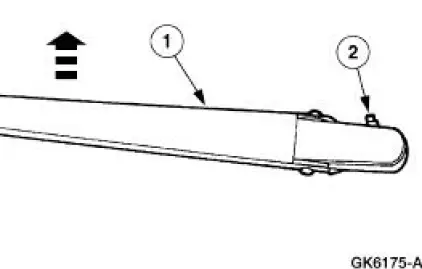

1. Pull up on the pivot arm.

2. Pull out on the retainer tab and remove the pivot arm.

Installation

1. To install, reverse the removal procedure.

Component Test

Component Test

Windshield Wiper Motor

CAUTION: Do not handle the wiper motor abusively when

diagnosing the wiper

operations. Failure to follow this caution may result in damage to the

motor magnets and wil ...

Mounting Arm and Pivot Shaft

Mounting Arm and Pivot Shaft

Removal

1. Park the windshield wipers in the full upright position. This will

allow for easy access to the

retaining clip on the wiper motor output shaft.

2. Remove the cowl top vent panels.

...

Other materials:

Shift Patterns

Upshifts

Transmission upshifting is controlled by the powertrain control

module (PCM). The PCM receives

inputs from various engine or vehicle sensors and driver demands to

control shift scheduling, shift feel

and torque converter clutch (TCC) opera ...

EGR System Components

The EGR system returns a portion of the exhaust gas to the intake manifold to

reduce the combustion

temperature. This results in lower nitrous oxide formation.

The powertrain control module (PCM) controls the EGR vacuum regulator solenoid .

The EG ...

Clutch Pedal Position (CPP) Switch

Removal

1. Disconnect the battery ground cable. For additional information,

refer to Section.

2. Disconnect the connector.

3. Remove the bolt and the clutch pedal position (CPP) switch.

Installation

1. To install, reverse the removal procedure. ...