Ford Mustang (1999-2004) Service Manual: Assembly

1. Lubricate all components with the recommended transmission fluid when reassembling.

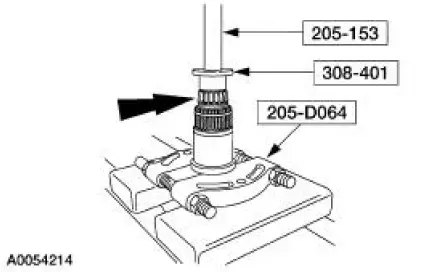

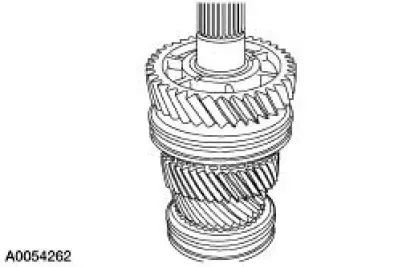

2. Using the special tools, press the output shaft front bearing on the output shaft.

3. Install the third gear bearing.

- Apply petroleum jelly to the bearing.

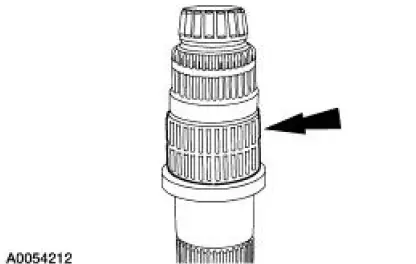

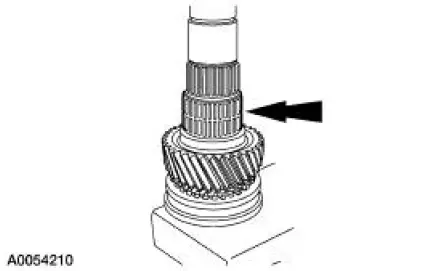

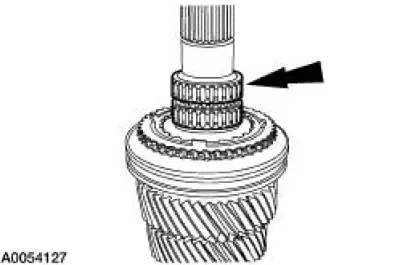

4. Install third gear, the third gear synchronizer blocking ring and the third/fourth gear synchronizer assembly. Position the output shaft with the output end facing upward. Using the special tool, press the third/fourth gear synchronizer assembly into place.

- Install the synchronizer body with the groove facing third gear.

- Stop press operation before keys engage the blocking ring slots. Lift and rotate the third gear and the blocking ring until the keys are seated in the blocking ring.

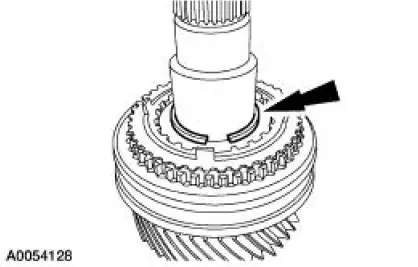

5. Install a new snap ring.

6. Install the second gear needle bearing.

- Apply petroleum jelly to the bearing.

7. Install second gear.

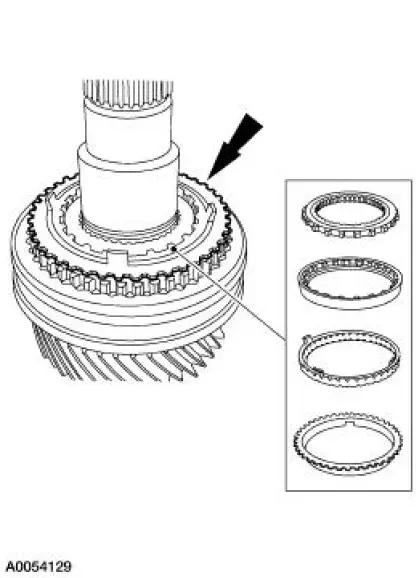

8. Install the second gear synchronizer thrust washer, the inner cone, the friction cone and the second gear synchronizer blocking ring.

- Align the blocking ring tabs with the second gear slots.

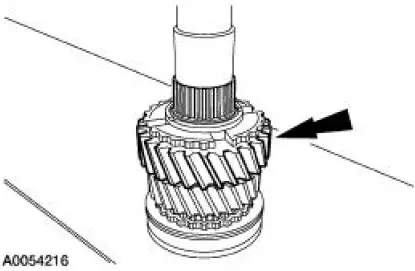

9. Install the first/second gear synchronizer assembly. Position the output shaft with the output end facing downward. Using the special tools, press the first/second gear synchronizer assembly into place.

- Install the synchronizer with the groove on the sleeve facing first gear.

- Stop press operation before keys engage the blocking ring slots. Lift and rotate the second gear and the blocking ring until the keys are seated in the blocking ring.

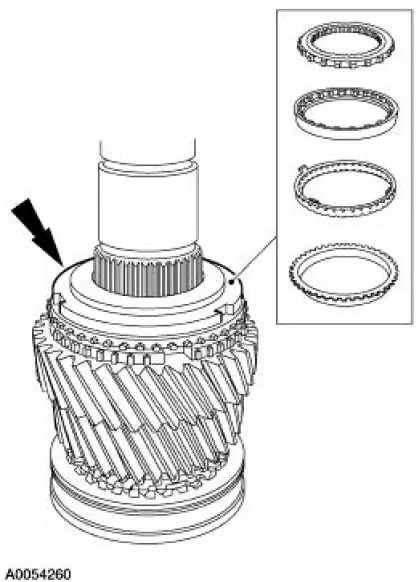

10. Install the first gear synchronizer thrust washer, the inner cone, the friction cone and the first gear synchronizer blocking ring.

11. Install a new snap ring.

12. Install the first gear needle bearing.

- Apply petroleum jelly to the bearing.

13. Install first gear.

- Rotate the gear to align the gear slots with the inner cone tabs.

14. Install a new rear output shaft bearing.

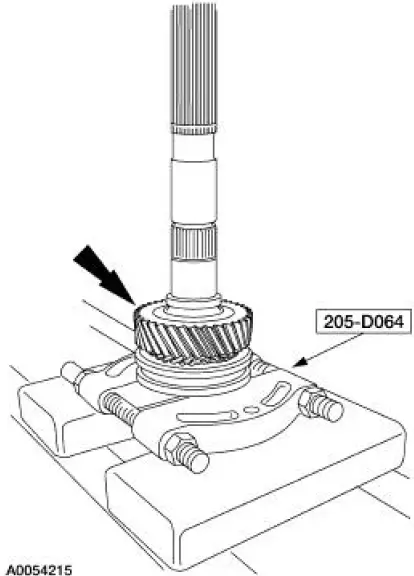

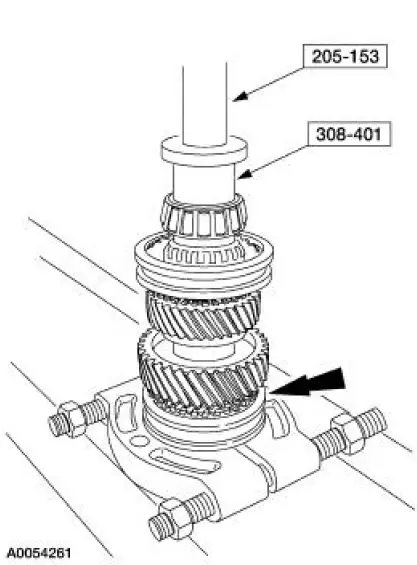

15. Using the special tools, install the fifth driven gear.

Disassembly

Disassembly

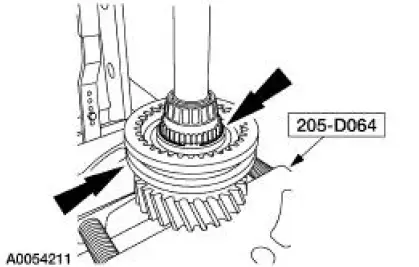

1. CAUTION: Hand tighten the special tool to prevent gear damage.

CAUTION: Support the output shaft while using the press to prevent

damage to the

shaft or gears.

Using the special tool and ...

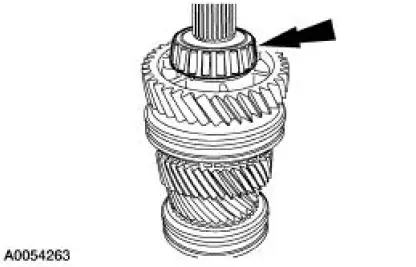

Countershaft

Countershaft

Special Tool(s)

Plate, Bearing Oil Seal

205-090 (T75L-1165-B)

Puller, Bearing

205-D064 (D84L-1123-A)

Installer, Drive Pinion Bearing

Cone

205-004 (T53T-4621- ...

Other materials:

Purging - CIII Power Steering Pump

Special Tool(s)

Vacuum Pump

416-D002 (D95L-7559-A) or

Equivalent

CAUTION: If the air is not purged from the power steering system

correctly, premature

power steering pump failure can result. This condition can occur on pre-delivery

vehicles ...

Lower Arm

Removal

CAUTION: Suspension fasteners are critical parts because they affect

performance of vital

components and systems and their failure can result in major service expense. A

new part with

the same part number must be installed if installation becomes nec ...

Transmission Case

Special Tool(s)

Handle

205-D055 (D81L-4000-A)

Installer, Bearing Cup

204-039 (T77F-1217-B)

Installer, Drive Pinion Bearing

Cup

205-054 (T71P-4616-A)

Installer, Rear Axle Oil Seal

205-155 (T80T-4000-Y)

...