Ford Mustang (1999-2004) Service Manual: Countershaft

Special Tool(s)

|

Plate, Bearing Oil Seal 205-090 (T75L-1165-B) |

|

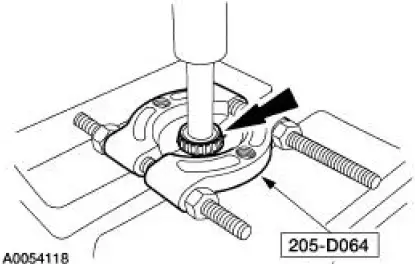

Puller, Bearing 205-D064 (D84L-1123-A) |

|

Installer, Drive Pinion Bearing Cone 205-004 (T53T-4621-B) |

|

Remover/Installer, Bearing Tube 308-025 (T75L-7025-C) |

|

Installer, Output Shaft Rear Bearing 308-401 |

|

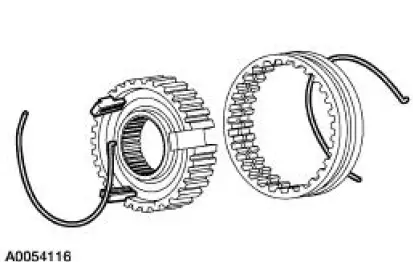

Adapter for 303-224 (Handle) 205-153 (T80T-4000-W) |

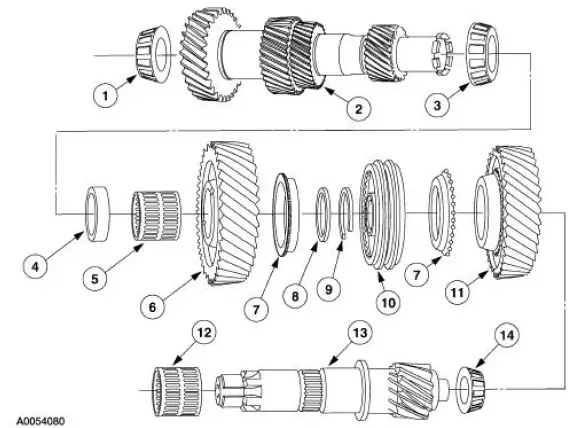

Disassembly and Assembly

1. Remove the thrust washer.

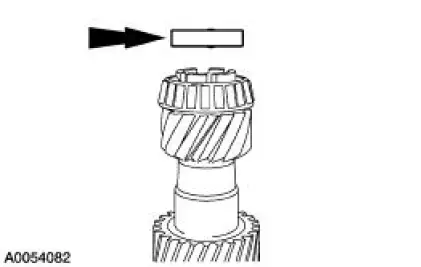

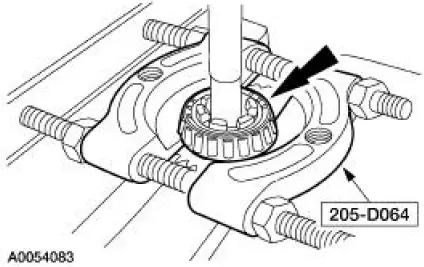

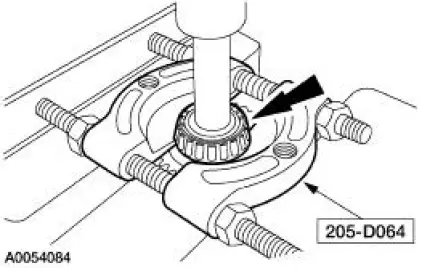

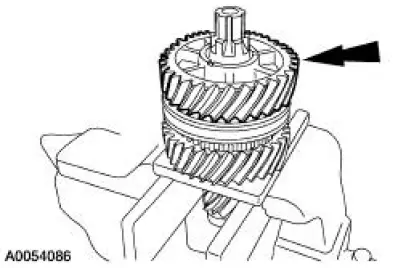

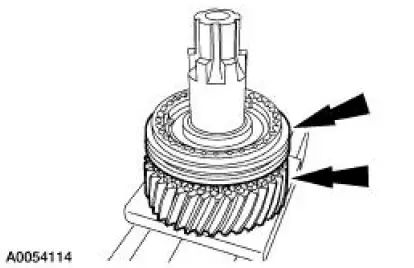

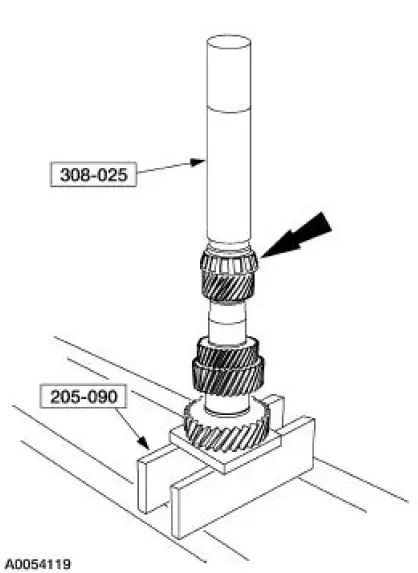

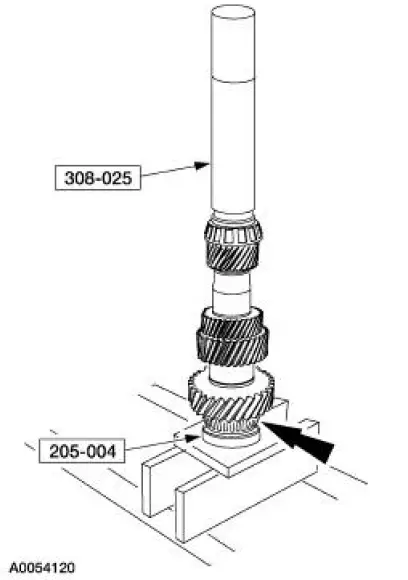

2. Using the special tool and a press, remove the countershaft rear bearing.

3. Using the special tool and a press, remove the countershaft front bearing.

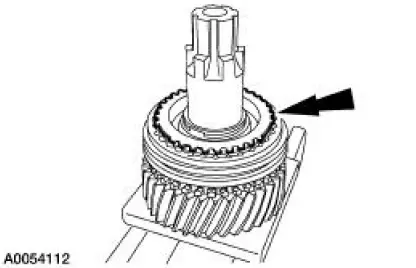

4. Place the special tool in a vise. Position the countershaft extension in the tool with the sixth drive gear facing upward. Remove the fifth/sixth shift fork.

5. Remove the sixth drive gear.

6. Remove the sixth drive gear needle bearing.

7. Remove the sixth drive gear synchronizer blocking ring.

8. Remove and discard the fifth/sixth synchronizer snap ring.

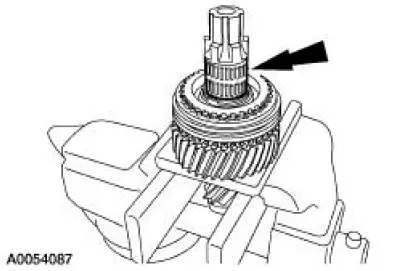

9. Using the special tool, press the fifth/sixth synchronizer and the fifth drive gear off the shaft.

10. Remove the fifth drive gear needle bearing.

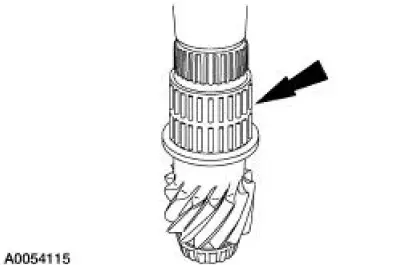

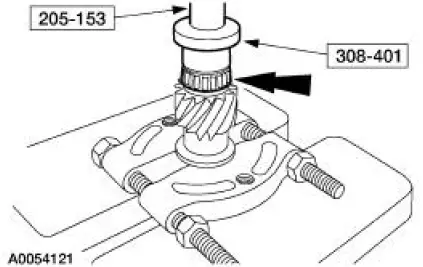

11. Using the special tool, remove the countershaft extension bearing.

12. Inspect the countershaft and countershaft extension.

- Check the shaft surface for wear or damage. Install a new shaft as necessary.

- Check the gear teeth for wear, pitting, scoring, spalling or fractures. Install new components as necessary.

13. Disassemble the fifth/sixth gear synchronizer assembly.

14. Inspect the fifth/sixth synchronizer.

- Check for worn, nicked or broken teeth. Install a new synchronizer as necessary.

- Check keys for wear or distortion. Install a new synchronizer as necessary.

- Check springs for distortion. Install a new synchronizer as necessary.

15. Inspect the fifth/sixth synchronizer blocking rings.

- Check for wear or damage. Install new synchronizer blocking rings as necessary.

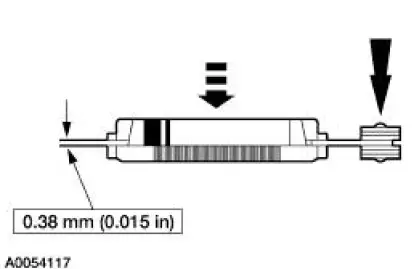

- Check the clearance between the synchronizer blocking ring and the gear.

- Position the blocking ring onto the gear. Make sure the correct blocking ring is measured with the correct gear and that the blocking ring is fully seated on the gear.

- Insert a feeler gauge and measure the clearance, while applying pressure and rotating the blocking ring. The measurement should be the same around the entire circumference. If the clearance is less than 0.38 mm (0.015 in), install new blocking rings.

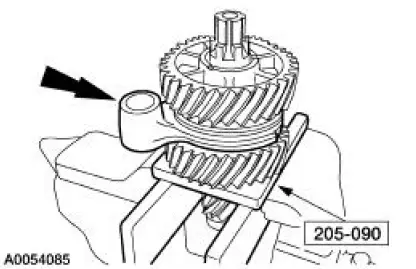

16. Using the special tools, install the countershaft rear bearing.

17. Using the special tools, install the countershaft front bearing.

18. Using the special tools, install the countershaft extension bearing.

19. To assemble, reverse the disassembly procedure.

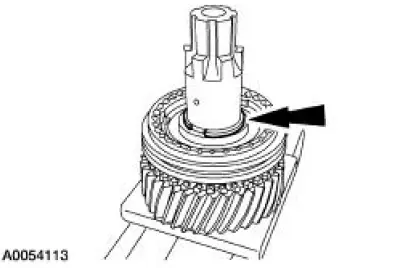

- Assemble the synchronizer assembly before installing.

Assembly

Assembly

1. Lubricate all components with the recommended transmission fluid when

reassembling.

2. Using the special tools, press the output shaft front bearing on the output

shaft.

3. Install the third g ...

Synchronizers

Synchronizers

Disassembly and Assembly

NOTE: This procedure applies to all synchronizer assemblies.

1. NOTE: Synchronizer components are not interchangeable. During

disassembly, mark each

individual synchronizer f ...

Other materials:

Ford Extended Service Plan

FORD ESP EXTENDED SERVICE PLANS

PROTECT YOURSELF FROM THE RISING COST OF VEHICLE REPAIRS

WITH A FORD EXTENDED SERVICE PLAN.

SERVICE PLANS (U.S. only)

More than 32 Million Ford and Lincoln owners have discovered the

powerful protection Ford ESP. It is the only ...

Floor mats

WARNING: Always use floor mats that are designed to fit the

footwell of your vehicle. Only use floor mats that leave the pedal

area unobstructed. Only use floor mats that are firmly secured to

retention posts so that they cannot slip out of position and inter ...

Accelerator Cable - 3.8L

Removal and Installation

1. Push the accelerator cable nylon bushing out of the accelerator pedal and

shaft arm.

2. Remove the bolts retaining the accelerator cable to the dash panel.

3. Disconnect the accelerator cable from the throttle body by rotating ...