Ford Mustang (1999-2004) Service Manual: Assembly

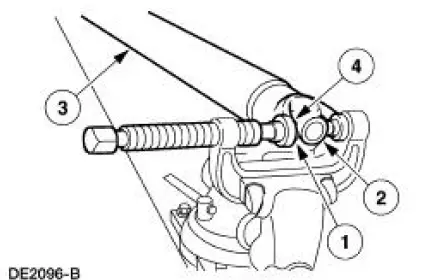

1. NOTE: Universal joint kits are to be installed as complete assemblies only. Do not mix components from other U-joint kits.

Install the spider.

1. Start a new bearing cup into the driveshaft yoke.

- Check the needle bearings for correct positioning.

2. Position the new spider in the driveshaft yoke.

3. Position the driveshaft in the U-joint tool.

4. Press the bearing cup to just below the snap ring groove.

- Repeat for the other bearing cup.

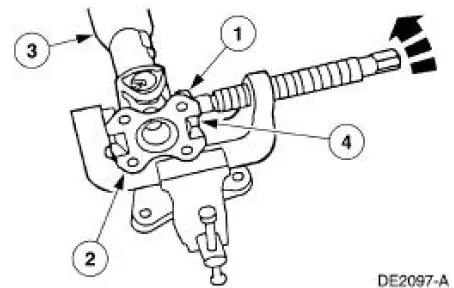

2. Inspect the driveshaft flange yoke. Install new if necessary.

3. Install the driveshaft flange yoke.

1. Start a new bearing cup into the driveshaft flange yoke.

- Check the needle bearings for correct positioning.

2. Position the driveshaft flange yoke.

3. Position the driveshaft in the U-joint tool.

4. Press the bearing cup to just below the snap ring groove.

- Repeat for the other bearing cup.

4. NOTE: Use the yellow snap rings supplied in the kit to assemble the universal joint (U-joint). If difficulty is encountered with the yellow snap rings, install the black snap rings, as required.

Remove the driveshaft from the U-joint tool, and install the four snap rings.

5. NOTE: Do not strike the bearings.

Check the U-joints for freedom of movement.

- If binding, strike the yoke with a brass or plastic hammer.

6. Install the driveshaft. For additional information, refer to Driveshaft in this section.

Disassembly

Disassembly

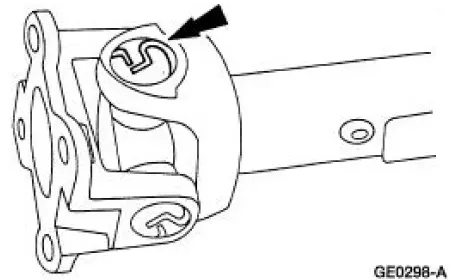

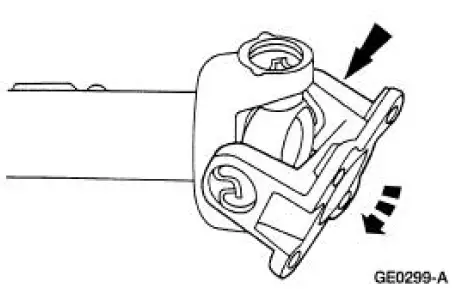

1. Remove the driveshaft (4602). For additional information, refer to

Driveshaft in this section.

2. CAUTION: Under no circumstances is the driveshaft assembly to be

clamped in the

jaws of a vise o ...

Rear Drive Axle/Differential - Ford 7.5-Inch Ring Gear

Rear Drive Axle/Differential - Ford 7.5-Inch Ring Gear

General Specifications

a: In-vehicle repair refill capacities are determined by filling the rear axle

with the specified lubricant to

6.4-14.3-mm (1/4-9/16-in) below the bottom of the fill hole.

To ...

Other materials:

Flexplate

Removal and Installation

1. Remove the transmission. For additional information, refer to Section.

2. Remove the six bolts retaining the flexplate to crankshaft, and remove the

flexplate.

3. To install, reverse the removal procedure.

Tighten the bolts in ...

Exhaust Manifold LH

Special Tool(s)

Lifting Bracket, Engine

303-D088 (D93P-6001-A2)

Support Bar, Engine

303-290-A

Removal and Installation

1. Install the special tool.

2. Install the special tools.

3. Raise and support the vehicle. For additional ...

Generator and Regulator

General Specifications

Torque Specifications

Generator

The charging system consists of the:

generator (GEN)

internal voltage regulator

The generator has an internal voltage regulator that is not installed

separately. The generator and

v ...