Ford Mustang (1999-2004) Service Manual: Assembly

1. CAUTION: Before beginning assembly, carry out and inspect the following: When building up subassemblies and assembling the transmission, ALWAYS use new gaskets and seals.

All fasteners must be tightened to the torque specification indicated. In addition to appearing in the section, the necessary torques can be found in the General Specifications Chart.

When building up subassemblies, each component part should be lubricated with clean transmission fluid. It is also good practice to lubricate the subassemblies as they are installed in the case.

Needle bearings, thrust washers and seals should be lightly coated with petroleum jelly during subassembly buildup or transmission assembly.

Many components and surfaces in the transmission are precision machined. Careful handling during disassembly, cleaning, inspection and assembly can prevent unnecessary damage to machined surfaces.

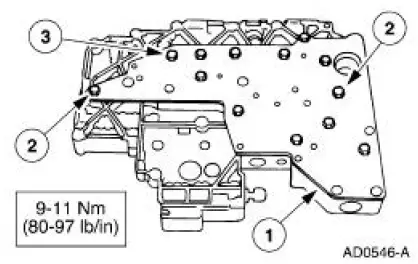

Install the valve body cover plate.

1. Position the valve body cover plate gasket and cover plate.

2. Install the two guide pin bolts.

3. Install the bolts.

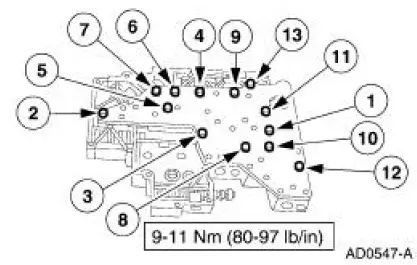

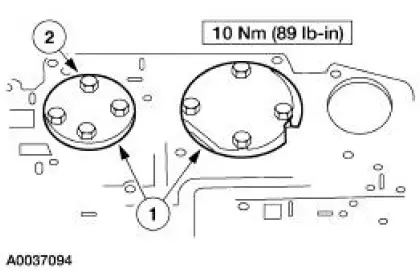

2. Tighten the bolts in the sequence shown.

3. Install the eight coasting booster valve shuttle balls.

4. Install the converter drain back valve and solenoid pressure supply screen.

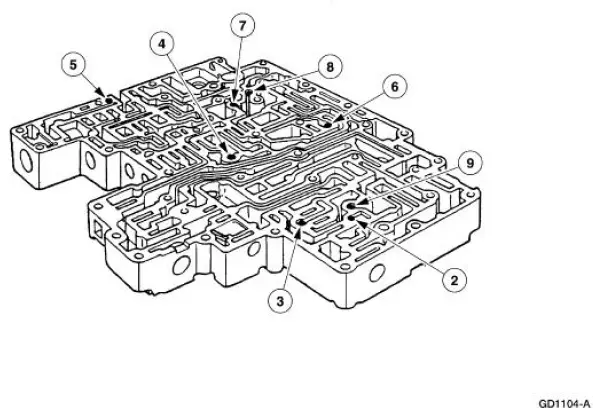

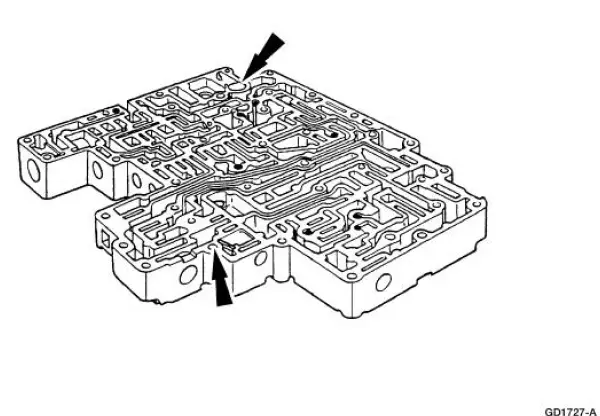

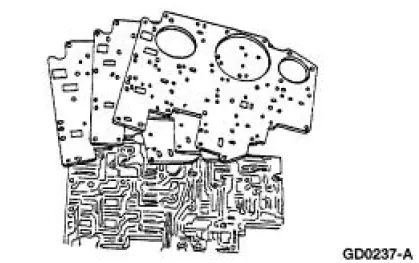

5. Install the separator plate and gaskets.

6. Install the two reinforcement plates.

1. Position the plates.

2. Install the bolts.

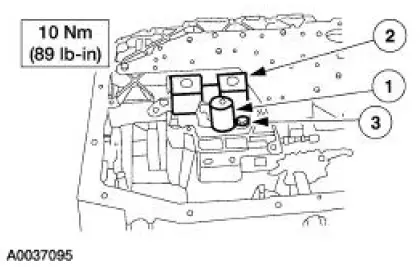

7. NOTE: Inspect the shift solenoid O-rings and TCC solenoid O-rings for damage.

Install the shift solenoid.

1. Position the TCC solenoid.

2. Position the shift solenoid.

3. Install the bolt.

Disassembly

Disassembly

Main Control Valve Body - Disassembled View

1. Remove the torque converter clutch (TCC) solenoid and the shift solenoid.

1. Remove the bolt.

2. Remove the shift solenoid.

3. Remov ...

Pump and Intermediate Clutch Piston

Pump and Intermediate Clutch Piston

Special Tool(s)

Installer, Front Pump Fluid

Seal

307-014 (T63L-77837-A)

Protector, Piston Seal

307-339 (T95L-77005-A)

Pump and Intermediate Clutch Piston - Disassembled ...

Other materials:

Body Sealer Types And Applications

Liquid Butyl Sealer

HB Fuller E709-19554-B or equivalent meeting Ford Specification

ESB-M4G162-A:

Does not run.

Is fast drying.

Remains semi-elastic.

Can be used for seam sealing on the floorpan, wheelhouse, body

rocker panels, door ope ...

External Controls (Description and Operation)

The transmission shift cable transfers the transmission operating mode from

the gearshift lever to the

automatic transmission (7003). The indicated position of the transmission floor

mounted selector lever

is transferred to the transmission through the cable ...

Ignition switch

A. Off: The ignition is off.

Note: When you switch the ignition off and leave your vehicle, do not

leave your key in the ignition. This could cause your vehicle battery to

lose charge.

B. Accessory: Allows the electrical accessories such as the radio to

ope ...