Ford Mustang (1999-2004) Service Manual: Assembly

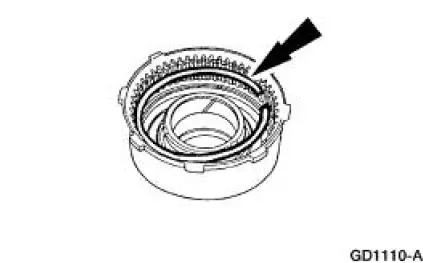

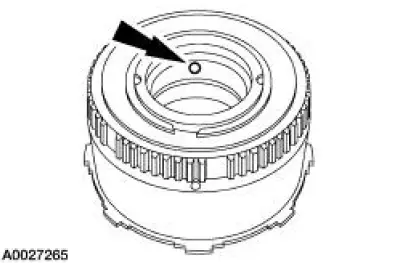

1. NOTE: One tab that locks the reverse clutch drum into the reverse sun shell may be removed.

This is done for balancing purposes.

Inspect the clutch cylinder thrust surfaces, piston bore and clutch plate serrations for scores or burrs. Minor scores or burrs may be removed with crocus cloth. Install a new clutch cylinder if badly scored or damaged.

2. Check the fluid passage in the clutch cylinder for obstructions. Clean out all fluid passages.

Inspect clutch piston for scores and install new if necessary. Inspect the check balls for freedom of movement and correct seating.

3. Check the clutch release spring for distortion and cracks. Install a new spring (including wave spring) if distorted or cracked.

4. Inspect the composition clutch plates, steel clutch plates and clutch pressure plate for worn or scored bearing surfaces. Install new parts if they are deeply scored or burred.

5. Check the clutch plates for flatness and fit on the clutch hub serrations. Discard any plate that does not slide freely on serrations or that is not flat.

6. Check the clutch hub thrust surfaces for scores and clutch hub splines for wear.

7. NOTE: The piston check ball must be present and moving freely.

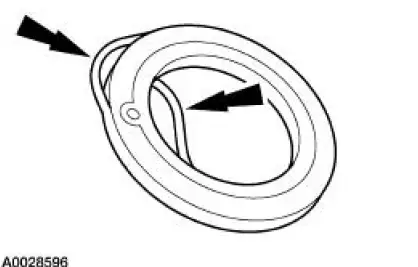

Install a new reverse clutch piston inner and outer seals.

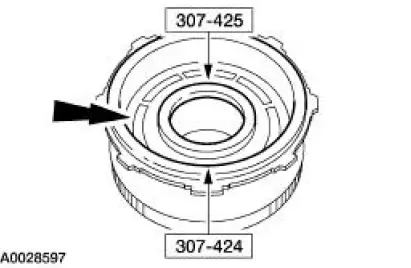

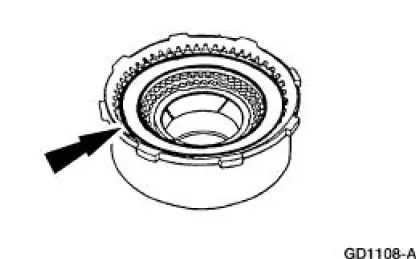

8. NOTE: Coat the reverse clutch piston inner seal, outer seal, drum sealing area and special tools with petroleum jelly.

Using the special tools, install the reverse clutch piston using even pressure to push it to the bottom of the reverse clutch drum.

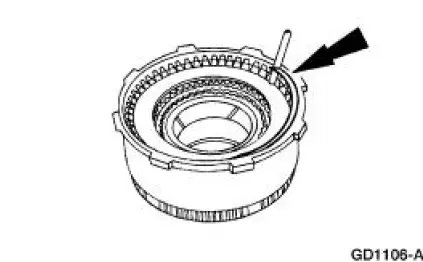

9. NOTE: The dished side of the reverse clutch piston spring must face the reverse clutch piston.

Install the reverse clutch piston spring.

1. Install the reverse clutch piston spring pressure ring.

2. Install the reverse clutch piston spring.

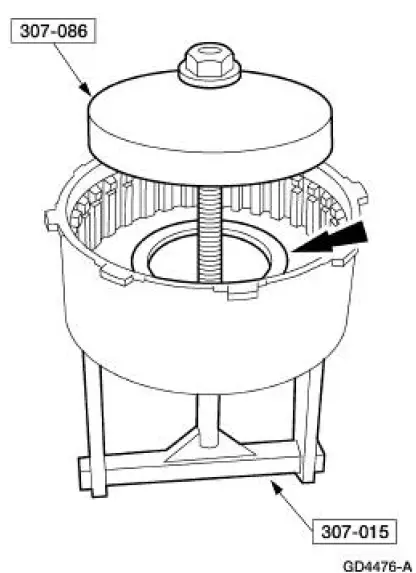

10. Using the special tools, compress the reverse clutch piston spring.

11. Install the reverse clutch piston spring retaining ring.

12. Remove the special tool.

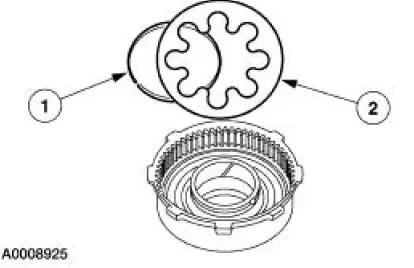

13. CAUTION: Install the pressure plates with the flat sides facing the clutch pack.

NOTE: Before assembly, soak the new clutch discs in clean automatic transmission fluid for 15 minutes.

Install the reverse clutch front pressure plate, clutch pack and reverse clutch rear pressure plate.

14. Install the reverse clutch pressure plate retainer snap ring.

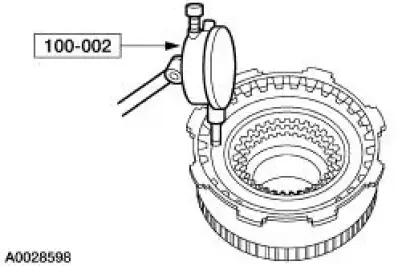

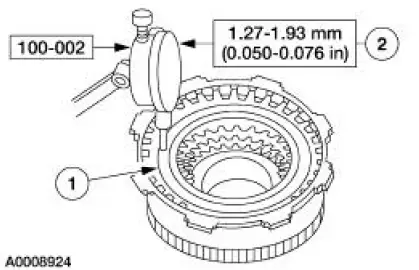

15. Install the special tool on the reverse clutch pack.

- Push downward on the clutch pack.

- Release pressure and zero the dial indicator.

16. Using the special tool check the reverse clutch pack clearance.

1. Lift up on the clutch pack until it fully seats against the reverse clutch pressure plate retainer.

2. Read the dial indicator.

- If clearance is not within specifications, install the correct size retaining ring.

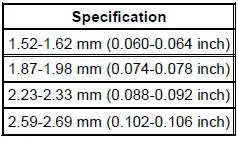

Selective Retaining Rings

17. Check the clutch for correct operation.

- Apply air pressure to the reverse clutch drum. The clutch should be heard and felt to work without leakage.

Disassembly

Disassembly

1. Inspect the clutch cylinder thrust surfaces, piston bore and clutch plate

serrations for scores or

burrs. Minor scores or burrs may be removed with a crocus cloth. Install a new

clutch cylinder i ...

Forward Clutch Cylinder

Forward Clutch Cylinder

Special Tool(s)

Dial Indicator Gauge with

Holding Fixture

100-002 (TOOL-4201-C) or

equivalent

Compressor, Clutch Spring

307-096 (T81P-70235-A)

Protector, Tra ...

Other materials:

Heated windows and mirrors (if equipped)

Heated Rear Window

Note: The vehicle must be running to use this feature.

Press the control to clear the rear window of thin ice and fog. Press the

control again within 15 minutes to switch it off. It turns off automatically

after approximately 15 minutes, or ...

Removal

1. Raise and support the vehicle.

2. Remove the wheel and tire assembly.

3. Remove the rear brake disc (2C026).

4. Remove the differential housing cover (4033) and drain the lubricant. For

additional information,

refer to Differential Housing Cover in t ...

Exhaust Manifold RH

Removal and Installation

1. Disconnect the battery negative cable. For additional information,

refer to Section.

2. Remove the air cleaner outlet pipe. For additional information, refer to

Section.

3. Disconnect the differential pressure feedback exha ...