Ford Mustang (1999-2004) Service Manual: Axle Housing Casting Porosity (Holes in Casting) Repair

CAUTION: To keep the axle's sound characteristics, do not disassemble the carrier.

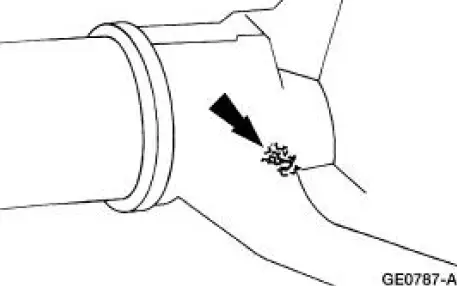

NOTE: Casting porosity is a condition where occasionally gas bubbles will form during the casting process leaving small pockets in the metal that will cause the axle housing to leak.

1. To fill small pockets, peen in a small amount of body lead.

2. Seal the pocket.

- Use epoxy sealer meeting Ford specification M-3D35A(E).

3. To fill large pockets, drill and tap a shallow hole for a small setscrew. Install the setscrew and seal it.

- Use epoxy sealer meeting Ford specification M-3D35A(E).

Axle Housing Weld Leaks Repair

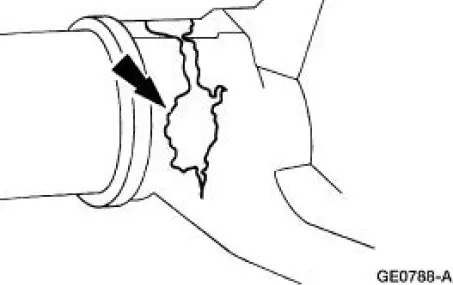

1. CAUTION: To keep the axle's sound characteristics, do not disassemble the carrier.

CAUTION: Rear axle housing straightness is too critical for field repair. Install a new axle housing if a weld is broken.

NOTE: Most minor weld leaks are repairable. This includes the puddle and fill welds that join the axle shaft tube to the axle housing on integral axles.

Seal the weld.

- Use Devcon Aluminum Liquid F2 or equivalent meeting Ford specification M-3D35A(E).

Driveline Angle Inspection

Driveline Angle Inspection

Special Tool(s)

Anglemaster II Driveline

Inclinometer

164-R2402 or equivalent

NOTE: An incorrect driveline angle can cause a vibration or shudder.

1. Check the vehicle for evidence o ...

Driveshaft

Driveshaft

Torque Specifications

Description

Nm

lb-ft

Pinion flange bolts

112

83

...

Other materials:

Inspection and Verification

WARNING: Never remove the pressure relief cap while the engine is

operating or when the

cooling system is hot. Failure to follow these instructions can result in damage

to the cooling

system or engine or personal injury. To avoid having scalding hot coolant ...

Disconnect

1. Remove the A/C tube lock coupling clip (19E746), if equipped.

2. Fit the special tool to the spring lock coupling.

3. Push the tool into the cage opening to release the female fitting from the

A/C tube lock coupling

spring (19E576).

4. Pull the sprin ...

Camshaft Lobe Lift

Special Tool(s)

Dial Indicator Gauge with

Holding Fixture

100-002 (TOOL-4201-C) or

equivalent

1. Use a Dial Indicator Gauge with Holding Fixture to measure camshaft

intake/exhaust lobe lift.

Rotate the camshaft and subtract the lowest ...