Ford Mustang (1999-2004) Service Manual: Brake Booster - Hydro-Boost (Description and Operation)

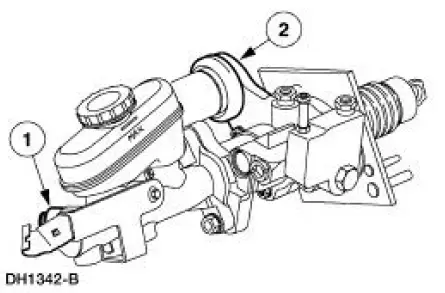

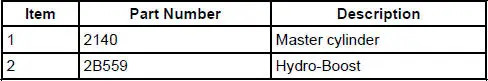

The Hydro-Boost brake booster is a hydraulically operated brake booster powered by the power steering pump (3A674). The power steering pump provides the fluid pressure to operate both the power brake booster and the power steering gear (3504).

A Hydro-Boost reserve system (accumulator) stores sufficient fluid under pressure to provide at least two power-assisted brake applications in the event the power steering pump fluid flow is interrupted.

For low assist concerns on vehicles equipped with the Hydro-Boost system, refer to Section to check the power steering pump pressure and flow.

The brakes can also be applied manually if the reserve system is depleted.

Any leakage goes directly back to the power steering pump reservoir (3E764).

Brake Booster - Vacuum (Description and Operation)

Brake Booster - Vacuum (Description and Operation)

Power Brake Booster

The vacuum type power brake booster (2005):

is a dual diaphragm, vacuum assisted power brake booster

reduces brake pedal force and travel distance.

is located on ...

Hydro-Boost Bleeding

Hydro-Boost Bleeding

1. NOTE: The Hydro-Boost power brake booster (2B560) is generally

self-bleeding, and the

following procedure will normally bleed the air from the power brake booster.

Normal operation

of the vehicle ...

Other materials:

Component Tests

Drive Belt Noise/Flutter

Drive belt chirp occurs due to pulley misalignment or excessive pulley runout.

It can be the result of a

damaged pulley or an incorrectly aligned pulley.

To correct, determine the area where the noise comes from. Check each of the

p ...

Windshield washers

Note: Do not operate the wipers on a dry windshield. This may scratch

the glass, damage the wiper blades or cause the wiper motor to burn out.

Always use the windshield washer before wiping a dry windshield.

Note: Do not operate the washer when the washer re ...

Using voice recognition

This system helps you control many features using voice commands.

This allows you to keep your hands on the wheel and focus on what is in

front of you.

Initiating a Voice Session

Push the voice icon; a tone sounds and Listening appears in the

display. Say an ...