Ford Mustang (1999-2004) Service Manual: Component Tests

Ball Joint Inspection

1. Raise and support the vehicle.

2. Prior to performing any inspection of the ball joints, inspect the wheel bearings.

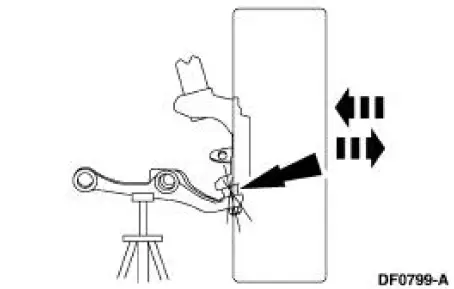

3. Position a safety stand beneath the front suspension lower arm (3079) to be tested.

4. While an assistant pulls and pushes the bottom of the tire, observe the relative movement between the lower spindle arm and the front suspension lower arm ball joint. Any movement at or exceeding the specification indicates a worn or damaged lower ball joint. Install a new front suspension lower arm.

Wheel Bearing Inspection

1. Raise the vehicle until the tire is off the floor.

2. NOTE: Make sure the wheel rotates freely and the brake pads are retracted sufficiently to allow movement of the tire and wheel assembly.

Grasp each tire at the top and bottom and move the wheel inward and outward while lifting the weight of the tire off the wheel bearing.

3. If the tire and wheel (hub) is loose on the wheel spindle or does not rotate freely, install a new front wheel hub (1104) as necessary.

Symptom Chart

Symptom Chart

Condition

Possible Sources

Action

Dogtracking

Excessive rear

thrust angle.

Front or rear

suspension

components.

Drive axle

damaged.

...

Camber and Caster Adjustment - Front

Camber and Caster Adjustment - Front

All vehicles

1. Remove the rivet. Loosen the nuts and bolt.

Vehicles requiring camber adjustment

2. Move the front suspension camber adjusting plate (3B391) to the required

camber setting.

Vehicl ...

Other materials:

Pinpoint Test I: LFC 33/DTC B1933 - Passenger Air Bag Circuit Resistance

High

Normal Operation

The restraints control module (RCM) monitors the resistance of the

passenger air bag ignitor by

measuring the resistance between pins 6 and 7. If the RCM detects high

resistance between these

pins, it will store a diagnostic trouble cod ...

Door Speaker - Lower

Removal and Installation

1. Remove the front door trim panel (239420). For additional

information, refer to Section

2. Remove the speaker (18808).

1. Remove the screws.

2. Disconnect the electrical connector.

3. Remove the speaker.

3. ...

Troubleshooting

Your SYNC system is easy to use. However, should questions arise, see

the tables below.

Use the website at any time to check your phone’s compatibility,

register your account and set preferences as well as access a

customer representative via an online chat ...