Ford Mustang (1999-2004) Service Manual: Cylinder Heads (Removal)

Special Tool(s)

|

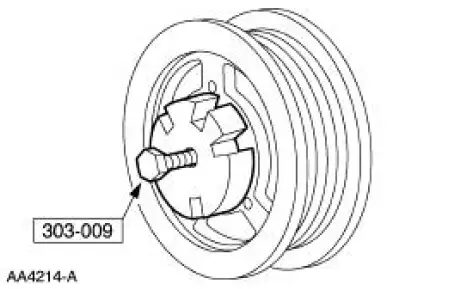

Remover, Crankshaft Vibration Damper 303-009 (T58P-6316-D) |

|

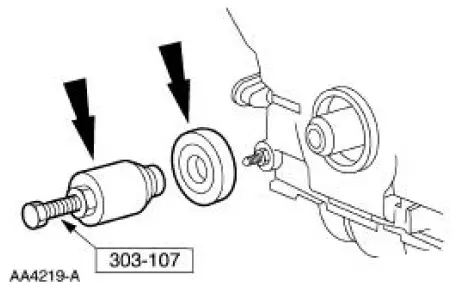

Remover, Crankshaft Front Oil Seal 303-107 (T74P-6700-A) |

|

Engine Lift Bracket Set 303-DS086 (D93P-6001-A) |

|

Compressor, Valve Spring (Exhaust) 303-567 (T97P-6565-AH) |

|

Compressor Spacer, Valve Spring 303-382 (T91P-6565-AH) |

|

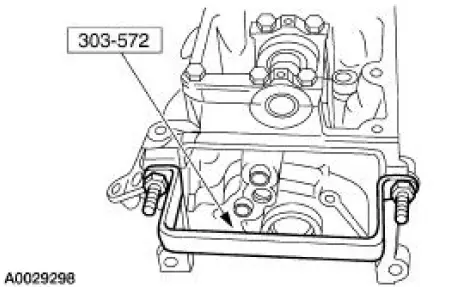

Remover/Installer, Cylinder Head 303-572 (T97T-6000-A) |

Material

| Item | Specification |

| Motorcraft Silicone Gasket Remover ZC-30 | - |

| Motorcraft Metal Surface Prep ZC-31 | - |

Removal

Both cylinder heads

1. Remove the engine. For additional information, refer to Engine in the Removal portion of this section.

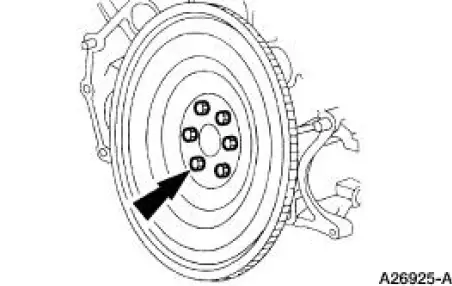

2. Remove the flywheel.

3. Remove the separator plate.

4. Mount the engine on a suitable engine stand.

5. NOTE: RH shown, LH similar.

Remove the RH and LH lifting eyes.

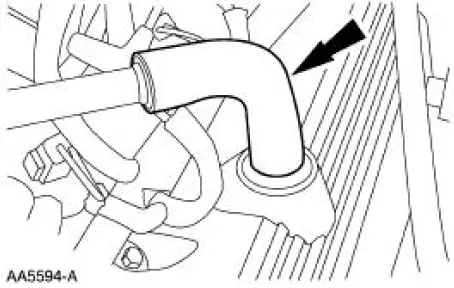

6. Remove the breather tube.

7. Disconnect the differential pressure feedback exhaust gas recirculation (EGR) electrical connector.

8. Disconnect the hoses from the differential pressure feedback EGR transducer.

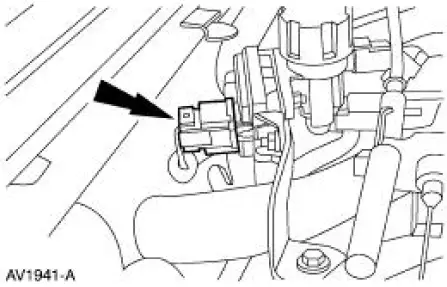

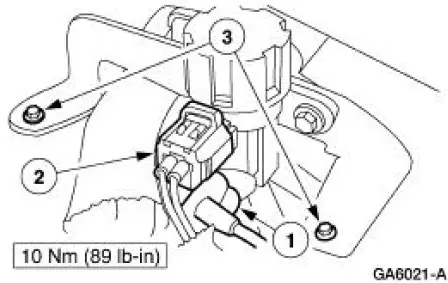

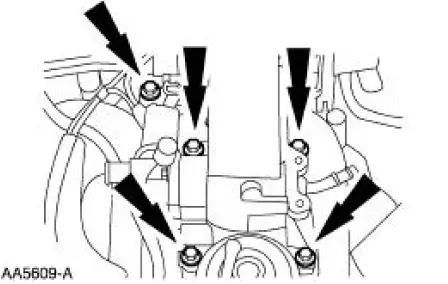

9. Remove the EGR vacuum regulator solenoid.

1. Remove the vacuum lines.

2. Remove the electrical connector.

3. Remove the bolts.

10. Disconnect the EGR tube from the EGR valve.

11. Disconnect the positive crankcase ventilation (PCV) hose from the base of the throttle body.

12. Remove the PCV valve and hose as an assembly.

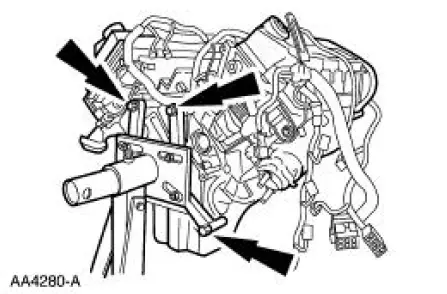

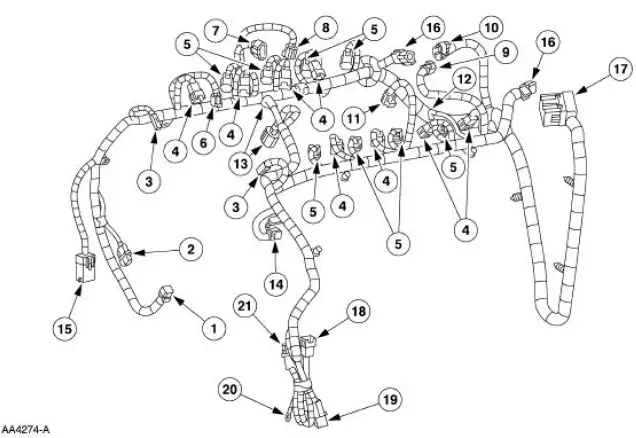

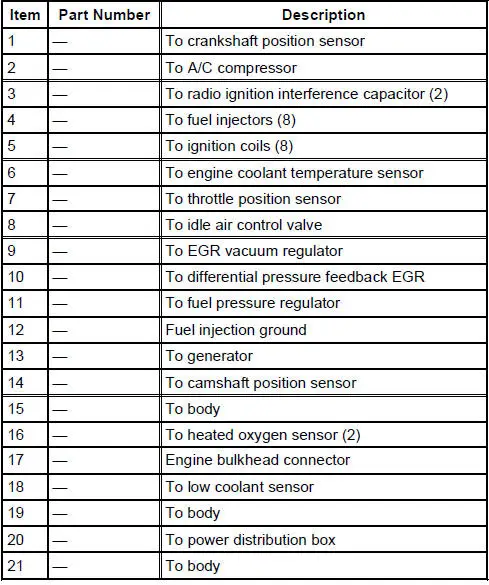

13. Remove the engine wiring harness.

14. Disconnect the vacuum line from the fuel pressure sensor.

15. Remove the throttle body bolts.

16. NOTE: The gasket is reusable if not damaged.

Remove the throttle body and adapter as an assembly.

- Inspect and clean the sealing surfaces.

17. Remove the ignition coils.

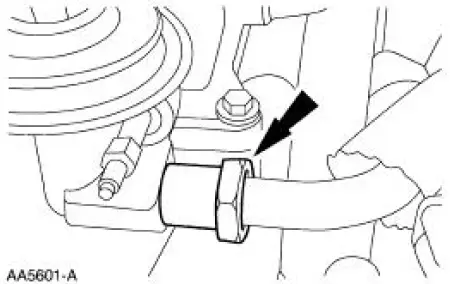

18. Remove the radio interference capacitors.

19. Remove the accessory drive belt.

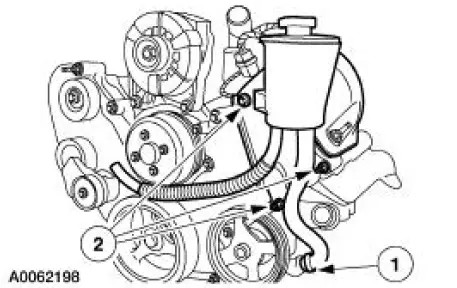

20. Remove the power steering reservoir and bracket as an assembly.

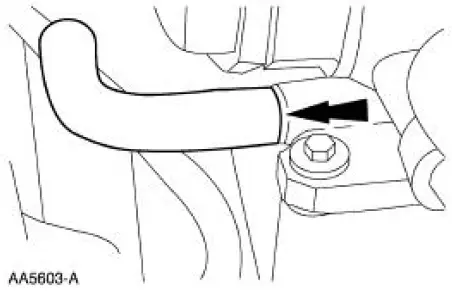

1. Disconnect the supply line from the pump.

2. Remove the (3) bolts and the reservoir and bracket.

21. Remove the upper generator support bracket.

22. Remove the bolts and the generator.

23. Remove the coolant outlet adapter.

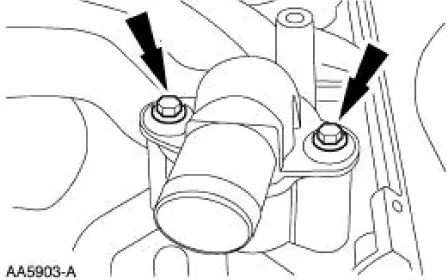

24. Remove the thermostat and O-ring.

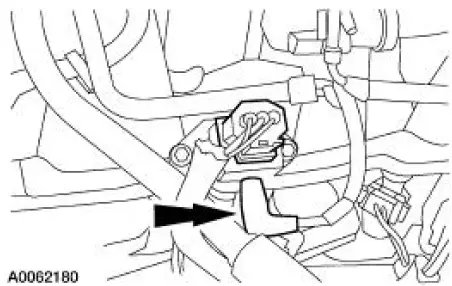

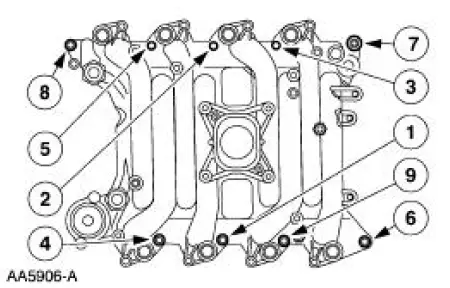

25. Remove the bolts in the sequence shown, and remove the intake manifold.

26. Remove the intake manifold gaskets.

27. CAUTION: Do not use metal scrapers, wire brushes, power abrasive discs or other abrasive means to clean sealing surfaces. These tools will cause scratches and gouges which make leak paths.

Clean the sealing surfaces.

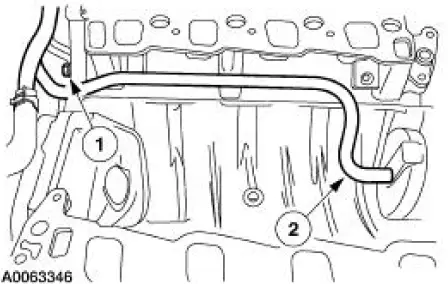

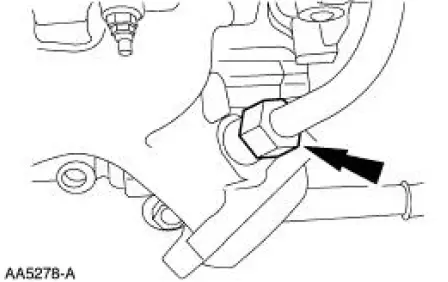

28. Remove the coolant bypass tube.

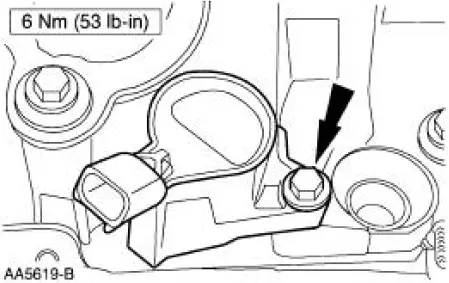

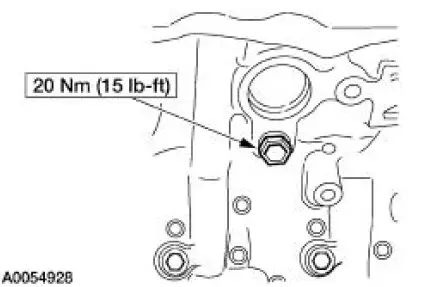

1. Remove the nut.

2. Remove the coolant bypass tube.

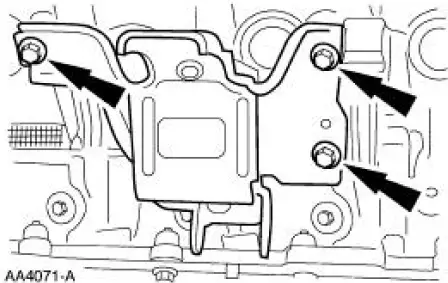

29. Remove the RH engine mount.

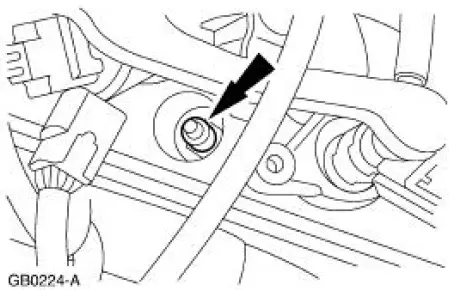

30. NOTE: LH shown; RH similar.

Using a suitable container, drain coolant from the engine block.

- Install the drain plugs when finished.

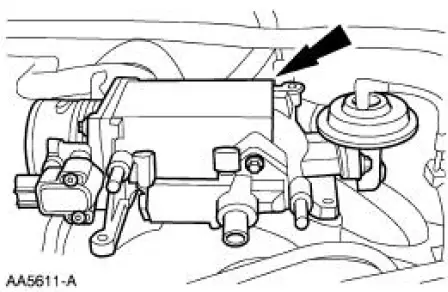

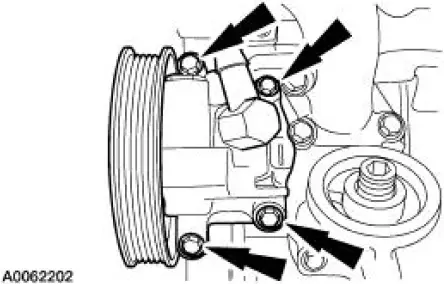

31. Remove the four bolts and the power steering pump.

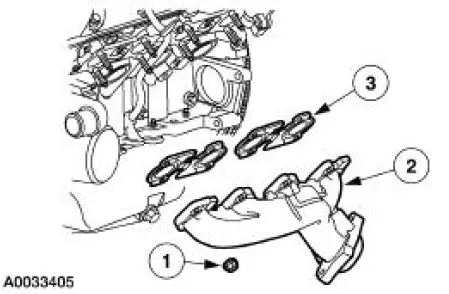

RH cylinder head

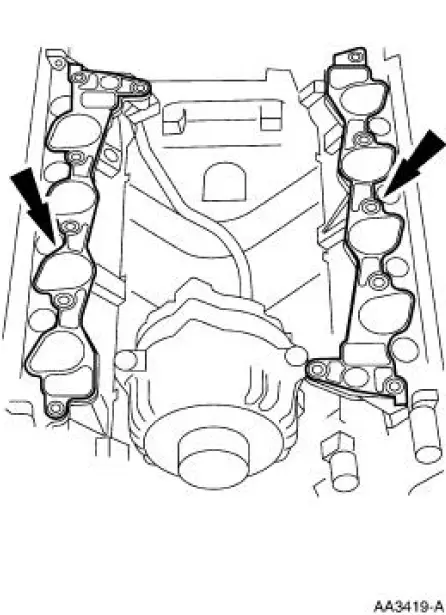

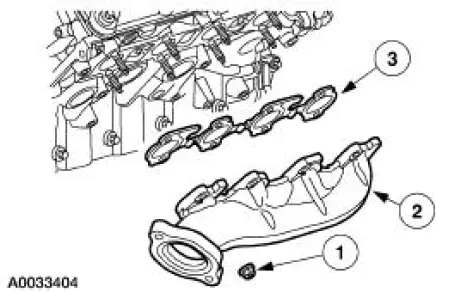

32. Remove the RH exhaust manifold.

1. Remove the RH exhaust manifold nuts.

2. Remove the RH exhaust manifold.

3. Remove the RH exhaust manifold gasket and discard.

LH cylinder head

33. Disconnect the EGR tube at the exhaust manifold.

34. Remove the LH exhaust manifold.

1. Remove the LH exhaust manifold nuts.

2. Remove the LH exhaust manifold.

3. Remove the LH exhaust manifold gasket and discard.

35. Remove the oil level indicator tube bolt.

36. Remove the oil level indicator tube.

Both cylinder heads

37. Clean and inspect the exhaust manifolds. For additional information, refer to Section.

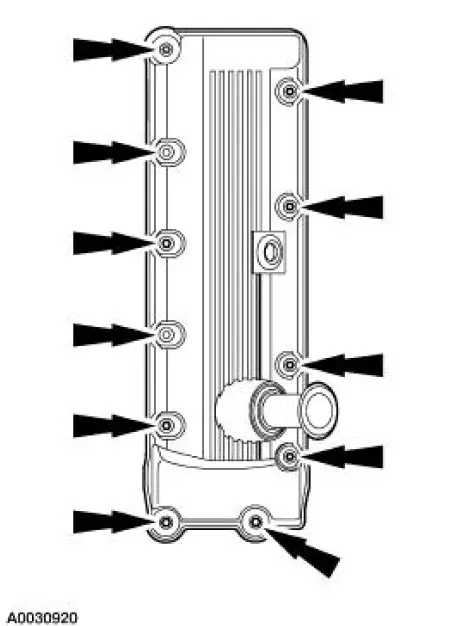

38. CAUTION: Do not use metal scrapers, wire brushes, power abrasive discs or other abrasive means to clean the sealing surfaces. These tools cause scratches and gouges which make leak paths. Use a plastic scraping tool to remove all traces of old sealant.

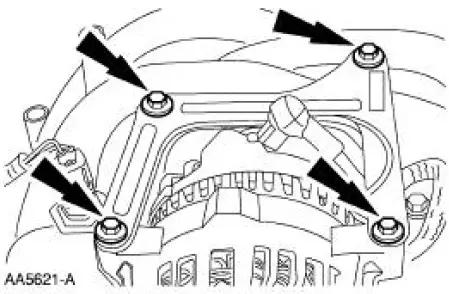

NOTE: The bolts are part of the valve cover and should not be removed. RH valve cover shown, LH valve cover similar.

Remove the RH and LH valve covers.

- Fully loosen the bolts and remove the valve covers.

- Clean the valve cover mating surface of the cylinder heads with silicone gasket remover and metal surface prep. Follow the directions on the packaging.

- Inspect the valve cover gasket(s). If the gasket(s) is damaged, remove and discard the gasket(s). Clean the valve cover gasket groove(s) with soap and water or a suitable solvent.

39. NOTE: Use compressed air to remove any foreign material from the spark plug well before removing the spark plugs.

NOTE: One spark plug shown, others are similar.

Remove the spark plugs.

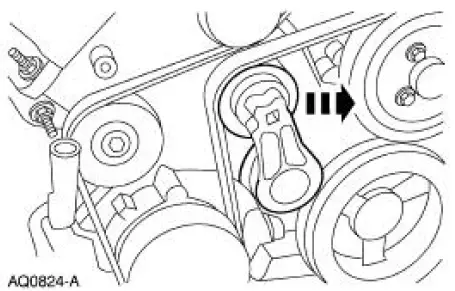

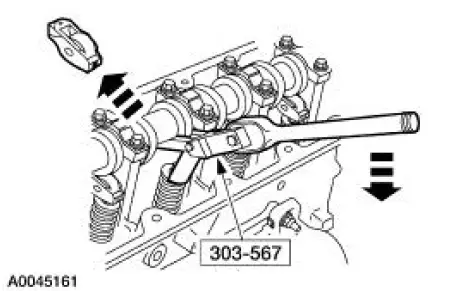

40. Install the special tool between the valve spring coils to prevent valve stem seal damage.

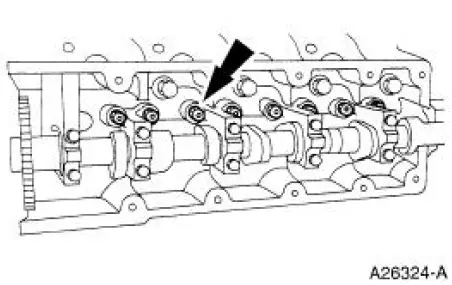

41. NOTE: Rotate the camshaft to see the base circle of the camshaft's lobe before removing the followers. Keep roller followers in order when removing.

Use the special tool to compress the valve springs and remove the 16 camshaft roller followers.

Rotate the camshaft and crankshaft as necessary.

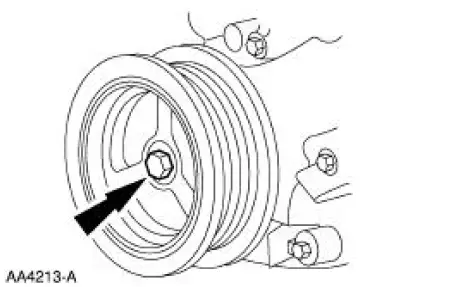

42. Remove the crankshaft pulley bolt.

43. Using the special tool, remove the crankshaft pulley.

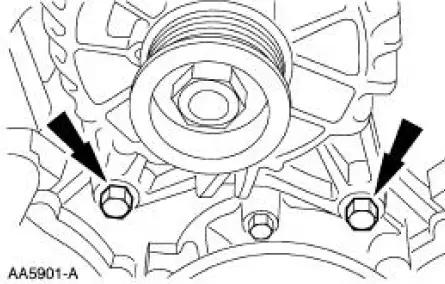

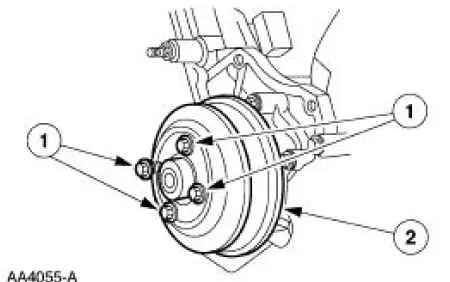

44. Remove the coolant pump pulley.

1. Remove the coolant pump pulley bolts.

2. Remove the coolant pump pulley.

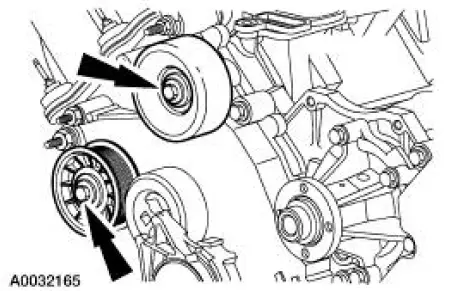

45. Remove the bolts and belt idler pulleys.

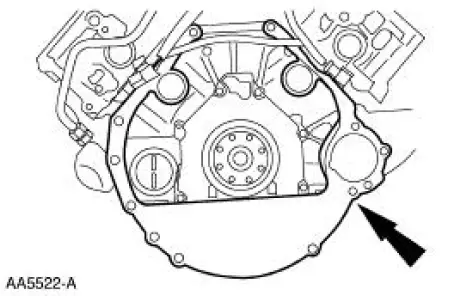

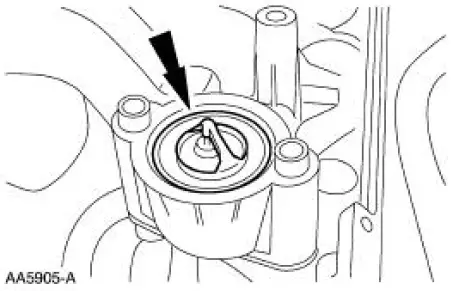

46. Using the special tool, remove the engine front cover seal.

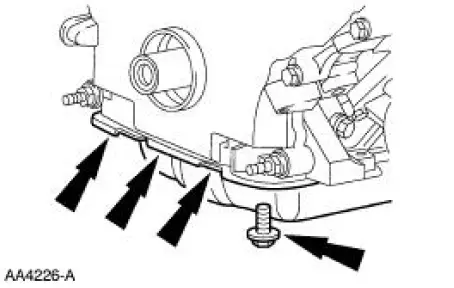

47. Remove the bolts.

48. Remove the bolts, the studs, and the engine front cover.

- Discard the gaskets, clean and inspect the sealing surfaces.

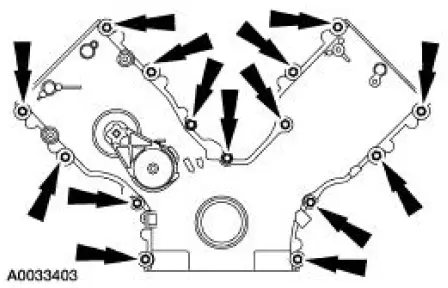

CAUTION: Since the engine is not free-wheeling, if the crankshaft or the camshafts are moved in any manner during removal and installation, the crankshaft and the camshafts must be re-synchronized.

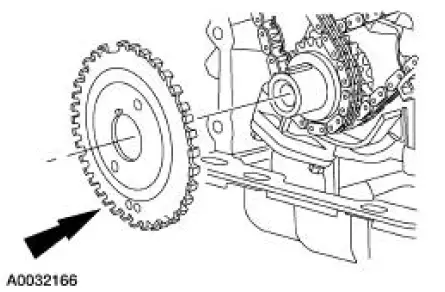

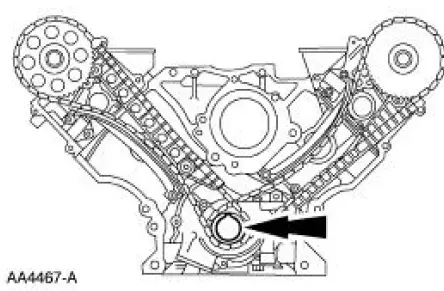

49. Remove the crankshaft sensor ring from the crankshaft.

50. Position the crankshaft with the keyway at the 12 o'clock position.

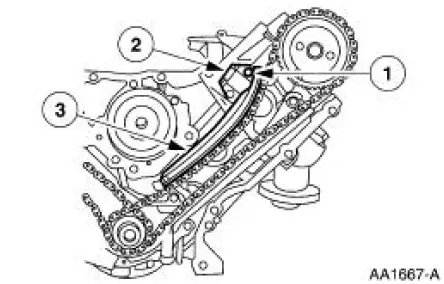

51. Remove the RH and LH timing chain tensioning system from both timing chains.

1. Remove the bolts.

2. Remove the timing chain tensioners.

3. Remove the timing chain tensioner arms.

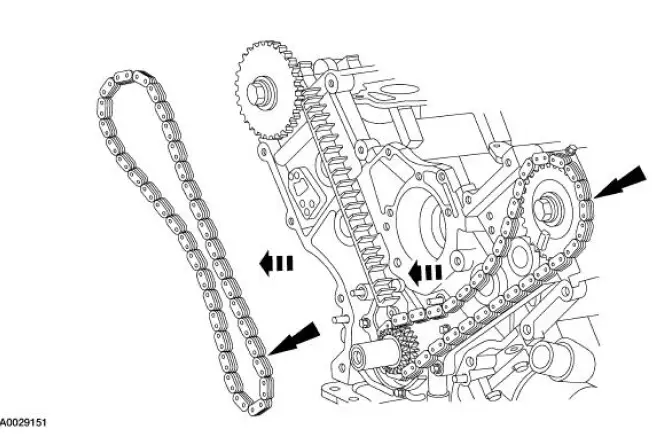

52. Remove the LH and RH timing chains and the crankshaft sprocket.

- Remove the RH timing chain from camshaft sprocket.

- Remove the RH timing chain from the crankshaft sprocket.

- Remove the LH timing chain from the camshaft sprocket.

- Remove the LH timing chain and crankshaft sprocket.

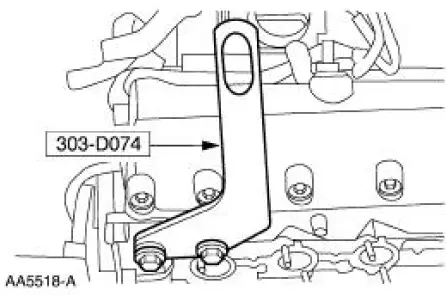

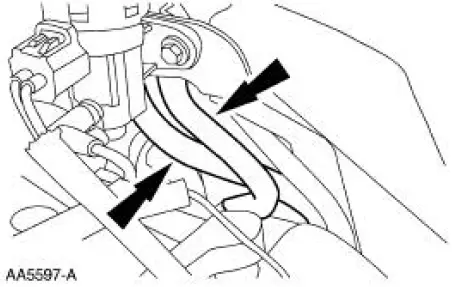

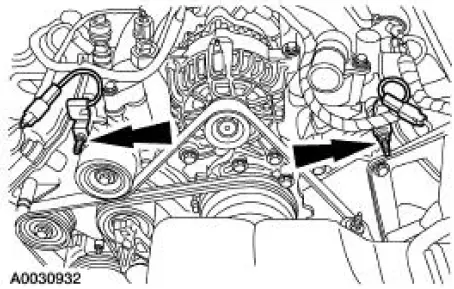

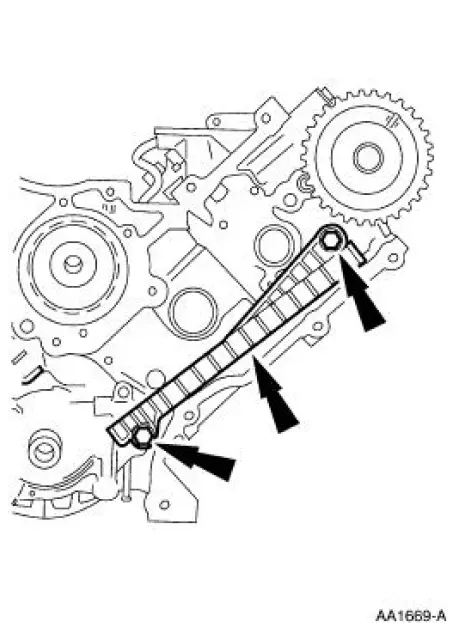

53. NOTE: LH shown; RH similar.

Remove the bolts and the timing chain guides.

54. NOTE: LH shown; RH similar.

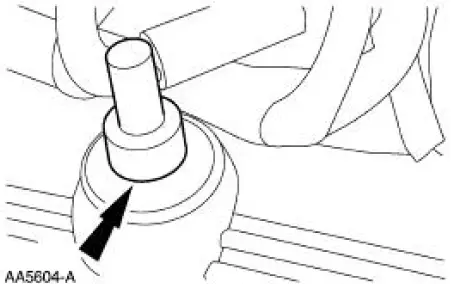

Install the lifting handles to the RH and LH cylinder heads.

55. NOTE: The hydraulic lash adjusters must be reinstalled in their original locations. Record the hydraulic lash adjuster locations.

Remove the hydraulic lash adjusters.

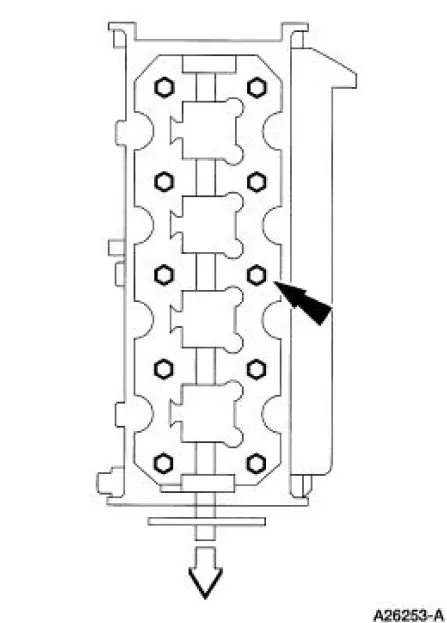

RH cylinder head

56. CAUTION: The cylinder head must be cool before removing it from the engine.

Cylinder head warpage can result if a warm or hot cylinder head is removed.

CAUTION: Place clean shop towels over exposed engine cavities. Carefully remove the towels so foreign material is not dropped into the engine.

CAUTION: The cylinder head bolts must be discarded and new bolts installed. They are tighten-to-yield designed and cannot be reused.

CAUTION: Do not use metal scrapers, wire brushes, power abrasive discs or other abrasive means to clean the sealing surfaces. These tools cause scratches and gouges that make leak paths. Use a plastic scraping tool to remove all traces of the head gasket.

CAUTION: Aluminum surfaces are soft and can be scratched easily. Never place the cylinder head gasket surface, unprotected, on a bench surface.

Remove the bolts and the RH cylinder head.

- Discard the cylinder head gasket.

- Discard the cylinder head bolts.

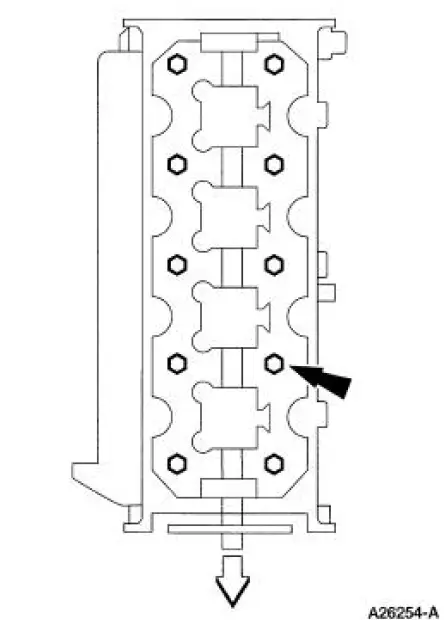

LH cylinder head

57. CAUTION: The cylinder head must be cool before removing it from the engine.

Cylinder head warpage can result if a warm or hot cylinder head is removed.

CAUTION: Place clean shop towels over exposed engine cavities. Carefully remove the towels so foreign material is not dropped into the engine.

CAUTION: The cylinder head bolts must be discarded and new bolts installed. They are tighten-to-yield designed and cannot be reused.

CAUTION: Do not use metal scrapers, wire brushes, power abrasive discs or other abrasive means to clean the sealing surfaces. These tools cause scratches and gouges that make leak paths. Use a plastic scraping tool to remove all traces of the head gasket.

CAUTION: Aluminum surfaces are soft and can be scratched easily. Never place the cylinder head gasket surface, unprotected, on a bench surface.

Remove the bolts and the LH cylinder head.

- Discard the cylinder head gasket.

- Discard the cylinder head bolts.

Both cylinder heads

58. CAUTION: Do not use metal scrapers, wire brushes, power abrasive discs or other abrasive means to clean the sealing surfaces. These tools cause scratches and gouges that make leak paths. Use a plastic scraping tool to remove all traces of the head gasket.

CAUTION: Observe all warnings or cautions and follow all application directions contained on the packaging of the silicone gasket remover and the metal surface prep.

NOTE: If there is no residual gasket material present, metal surface prep can be used to clean and prepare the surfaces.

Clean the cylinder head-to-cylinder block mating surfaces of both the cylinder head and the cylinder block.

1. Remove any large deposits of silicone or gasket material with a plastic scraper.

2. Apply silicone gasket remover, following package directions, and allow to set for several minutes.

3. Remove the silicone gasket remover with a plastic scraper. A second application of silicone gasket remover may be required if residual traces of silicone or gasket material remain.

4. Apply metal surface prep, following package directions, to remove any remaining traces of oil or coolant, and to prepare the surfaces to bond with the new gasket. Do not attempt to make the metal shiny. Some staining of the metal surfaces is normal.

59. NOTE: The straightedge used must be flat within 0.0051 mm (0.0002 in) per foot of tool length.

Support the cylinder head on a bench with the head gasket side up. Inspect all areas of the deck face with a straightedge, paying particular attention to the oil pressure feed area. The cylinder head must not have depressions deeper than 0.0254 mm (0.001 in) across a 38.1 mm (1.5 in) square area, or scratches more than 0.0254 mm (0.001 in) .

Engine Mount LH

Engine Mount LH

Special Tool(s)

Lifting Bracket, Engine

303-D088 (D93P-6001-A2)

Support Bar, Engine

303-290-A

Removal

1. Install the special tool.

2. Install the special tools.

3. Ra ...

Engine (Removal)

Engine (Removal)

Special Tool(s)

Special Tool(s)

Support Bracket, Engine

303-639

Spreader Bar

303-D089 (D93P-6001-A3)

Lifting Bracket Set, Engine

303-D074 (D91P-6001-A)

Re ...

Other materials:

Installation

1. NOTE: If the valve cover is not secured within four minutes, the sealant

must be removed and

the sealing area cleaned with metal surface cleaner. Allow to dry until there is

no sign of

wetness, or four minutes, whichever is longer. Failure to follow this ...

Fill

1. WARNING: Do not mix oil types, any mixture or any unapproved oil can

lead to seal

deterioration and leaks. A leak can ultimately cause loss of fluid, which can

result in a

loss of power steering assist.

Check the fluid level. If necessary, fill the reserv ...

Camshaft

Removal and Installation

1. Remove the timing chains. For additional information, refer to Timing

Drive Components in this

section.

2. Remove the roller followers. For additional information, refer to Camshaft

Roller Follower in this

section.

3. Remove the ...