Ford Mustang (1999-2004) Service Manual: Disassembly

1. Remove the driveshaft (4602). For additional information, refer to Driveshaft in this section.

2. CAUTION: Under no circumstances is the driveshaft assembly to be clamped in the jaws of a vise or similar holding fixture. Denting or localizing fracture can result, causing driveshaft failure during vehicle operation.

Place the driveshaft (4602) on a suitable workbench. Be careful not to damage the tube.

3. NOTE: If components are not marked and therefore installed incorrectly, driveline imbalance can occur.

Index-mark the driveshaft components.

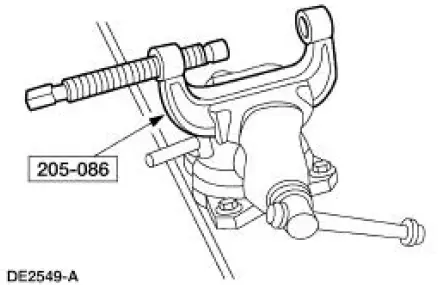

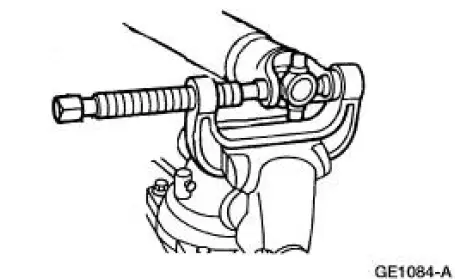

4. Clamp the special tool in a vise.

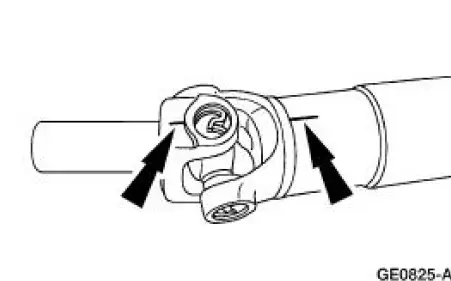

5. Remove all four of the snap rings.

6. NOTE: If necessary, use a pair of pliers to remove a bearing cup if it cannot be pressed out all the way.

Remove the driveshaft slip yoke (4841).

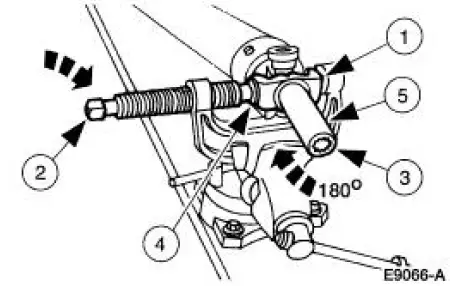

1. Position the driveshaft slip yoke in the U-joint tool.

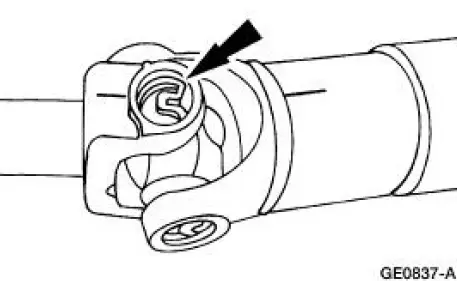

2. Press out a bearing cup.

3. Rotate the driveshaft slip yoke.

4. Press on the spider to remove the remaining bearing cup.

5. Remove the driveshaft slip yoke.

7. Repeat Step 5 to remove the remaining bearing cups and spider from the driveshaft.

8. Clean the yoke area at each end of the driveshaft.

Driveshaft Slip Yoke

Driveshaft Slip Yoke

Special Tool(s)

Installer/Remover, C Frame

and Screw

205-086 (T74P-4635-C)

...

Assembly

Assembly

1. NOTE: Universal joint service kits are to be installed as complete

assemblies only. Do not mix

components from other U-joint kits.

Install the bearing cup.

1. Start a new bearing cup into the d ...

Other materials:

Wheel Hub or Axle Flange Bolt Circle Runout

NOTE: The brake discs must be removed to carry out all runout

measurements.

1. Position the special tool perpendicular to the wheel hub or axle flange bolt,

as close to the hub

or flange face as possible. Zero the indicator to allow the pointer to deflect

...

Transmission Connector Layouts

Transmission Vehicle Harness Connector

Transmission Internal Harness Connector

Digital Transmission Range (TR) Sensor Connector

Output Shaft Speed (OSS) Sensor Harness Connector

Digital Transmission Range (TR) Senso ...

Changing a fuse

Fuses

WARNING: Always replace a fuse with one that has the

specified amperage rating. Using a fuse with a higher amperage

rating can cause severe wire damage and could start a fire.

If electrical components in your

vehicle are not working, a fuse may

have blo ...