Ford Mustang (1999-2004) Service Manual: Driveshaft (Removal and Installation)

Material

| Item | Specification |

| Threadlock and Sealer E0AZ-19554-AA | WSK-M2G351-A5 (type II) |

Removal and Installation

1. Raise and support the vehicle.

2. Carry out the following:

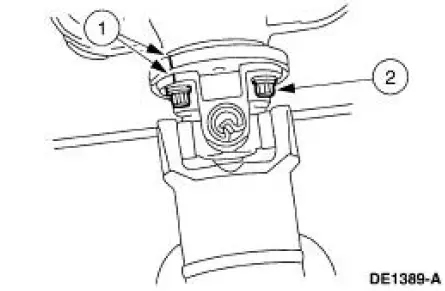

1. Place an index mark on the rear axle pinion flange and the driveshaft centering socket yoke.

2. Remove the four bolts.

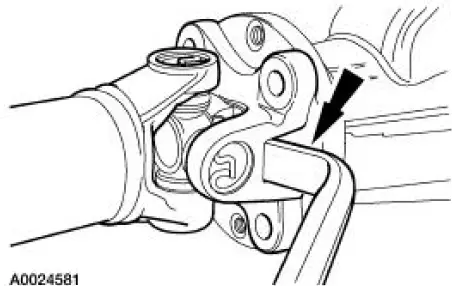

3. CAUTION: The driveshaft centering socket yoke fits tightly on the rear axle pinion flange pilot. Never hammer on the driveshaft or any of its components to disconnect the yoke from the flange. Pry only in the area shown, with a suitable tool, to disconnect the yoke from the flange.

Using a suitable tool as shown, disconnect the driveshaft centering socket yoke from the rear axle pinion flange.

4. CAUTION: Do not allow the slip yoke to bottom on the transmission output shaft.

Lower the rear end of the driveshaft to clear the rear axle housing. Pull the driveshaft rearward until the driveshaft slip yoke clears the transmission extension housing.

- Place a paint index mark on the driveshaft slip yoke and the transmission output shaft.

- Place a commercially available plug in the extension housing to prevent fluid leakage.

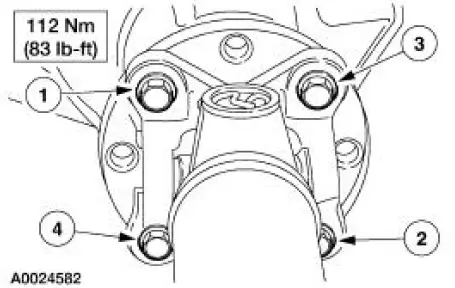

5. CAUTION: Install the driveshaft with new bolts. If new bolts are not available, apply threadlock and sealer to the threads of the original bolts.

CAUTION: Do not allow the slip yoke to bottom on the transmission output shaft.

CAUTION: The driveshaft centering socket yoke fits tightly on the rear axle pinion flange pilot. To make sure that the yoke seats squarely on the flange, tighten the bolts evenly in a cross pattern as shown.

NOTE: Clean all foreign material from the yoke areas of the driveshaft.

To install, reverse the removal procedure.

Universal Joints

Universal Joints

The universal joints are:

lubed-for-life design and require no lubrication.

equipped with nylon thrust washers, located at each base of the bearing

cup, which control end

play, position the need ...

Driveshaft - Cobra

Driveshaft - Cobra

Material

Item

Specification

Threadlock and Sealer

E0AZ-19554-AA

WSK-M2G351-A5 (type

II)

Silicone Lubricant

(Aerosol)

F5AZ-19553-AA

ESR-M13P4-A

Removal and Installatio ...

Other materials:

Latch - Luggage Compartment Lid

Removal

1. NOTE: The luggage compartment lid latch is equipped with

mechanical interior release handle.

Disconnect the luggage compartment lid lock actuator (432A38) cable.

2. Remove the luggage compartment lid latch (43200).

1. Disconnect the ...

Gear (Removal and Installation)

Special Tool(s)

Teflon Seal Replacer Set

211-D027 (D90P-3517-A) or

Equivalent

Tie Rod End Remover

211-001 (TOOL-3290-D)

Removal

1. Turn the steering wheel as necessary to position the wheels in the

straight-ahead position. Do

not loc ...

Switch - Door Lock

Removal

1. CAUTION: Place a rag between the window regulator switch

plate and the door trim

panel to avoid damaging the door trim panel.

Position the window regulator switch plate (14524) aside.

1. Pull at service notch.

2. Lift to release t ...