Ford Mustang (1999-2004) Service Manual: Engine (Assembly)

Special Tool(s)

|

Slide Hammer 307-005 (T59L-100-B) |

|

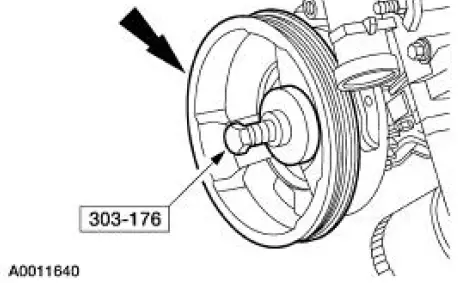

Remover Adapter, Vibration Damper 303-176 (T82L-6316-B) |

|

Installer, Crankshaft Front Seal 303-474 (T94P-6701-AH) |

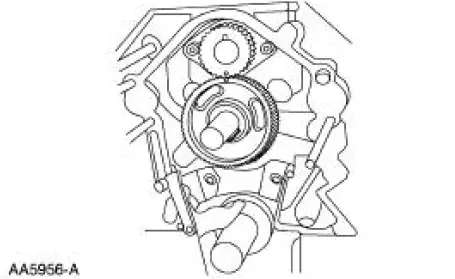

|

Replacer, Steering Pump Pulley 211-009 (T65P-3A733-C) |

|

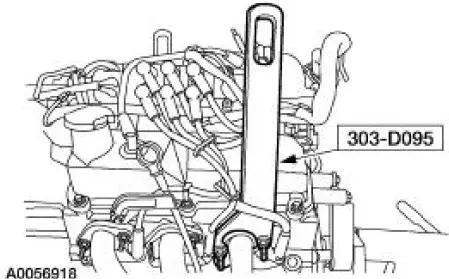

Engine Lift Bracket Set 303-D095 (D94L-6001-A) |

|

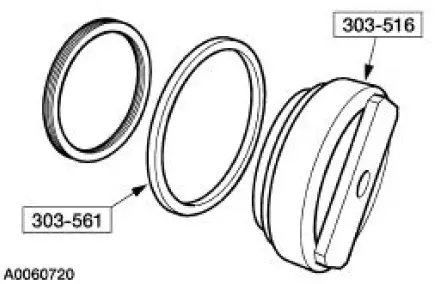

Replacer, Rear Crankshaft Seal 303-516 (T95P-6701-BH) |

|

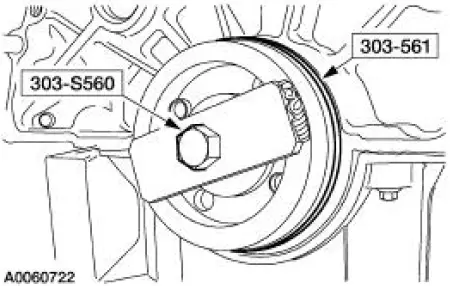

Spacer, Rear Crank Seal Replacer 303-561 (T96T-6701-B) |

|

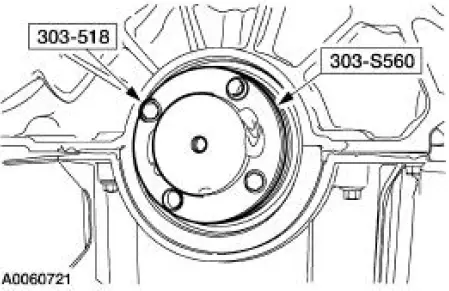

Adapter, Crankshaft Rear Seal (Use only the adapter retaining bolts) 303-518 (T95P-6701-DH) |

|

Adapter, Crankshaft Rear Seal (Use only the adapter and the center jack screw) 303-S560 (T96T-6701-A) |

|

Spreader Bar 303-D089 (D93P-6001-A3) |

Material

| Item | Specification |

| Metal Surface Cleaner F4AZ-19A536-RA or equivalent | WSE-M5B392- A |

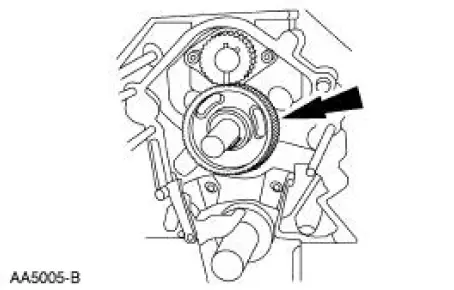

| Silicone Gasket and Sealant F7AZ-19554-EA or equivalent | WSE-M4G323- A4 |

| SAE 5W-20 Premium Synthetic Blend Motor Oil XO-5W20-QSP or equivalent | WSS-M2C153- H |

| Pipe Sealant with Teflon XW7Z-19554-AA | WSK-M2G350- A2 |

CAUTION: The moving components must be lubricated with clean engine oil before assembly.

CAUTION: The components with oil holes must be correctly aligned with the oil feed holes.

1. If necessary, install the following:

1. the cylinder block dowels.

2. the oil gallery plugs.

3. the water jacket plugs.

2. If equipped, install the engine coolant heater.

3. Using the camshaft bearing service set, install the engine dynamic balance shaft bearings.

4. Using the camshaft bearing service set, install the camshaft bearings.

5. Install the following:

1. the engine dynamic balance shaft bearing cover.

2. the camshaft bearing cover.

6. CAUTION: Do not damage the camshaft lobes when installing the camshaft.

Install the camshaft and the camshaft spacer.

7. Install the camshaft thrust plate.

1. Position the camshaft thrust plate.

2. Install the bolts.

8. Turn the camshaft so that the timing mark is at 12 o'clock and install the engine dynamic balance shaft assembly into the cylinder block. Turn the engine balance shaft driven gear so that the timing mark aligns up with the timing mark on the engine balance shaft drive gear.

9. NOTE: If correctly aligned, the engine dynamic balance shaft keyway will be at 12 o'clock and the camshaft keyway will be at 6 o'clock on the camshaft.

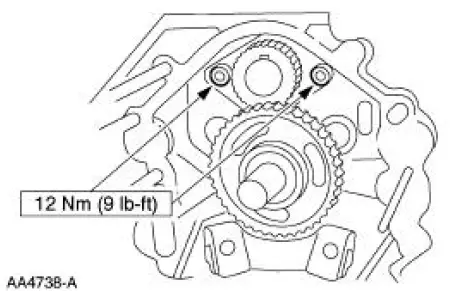

Install the bolts.

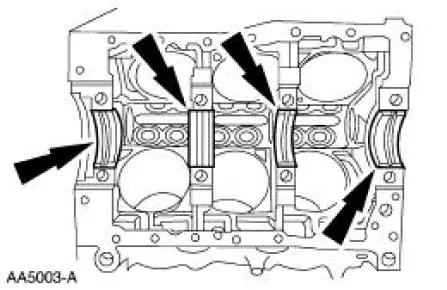

10. CAUTION: Make sure the components are installed in the correct location.

NOTE: Lubricate the crankshaft main bearings prior to installation.

Install the crankshaft upper main bearings and the crankshaft upper thrust main bearing.

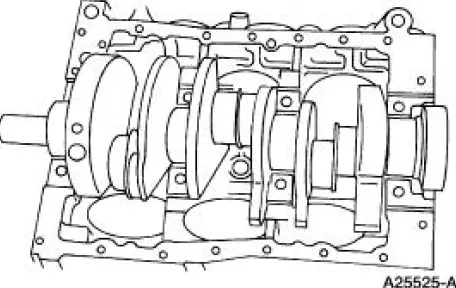

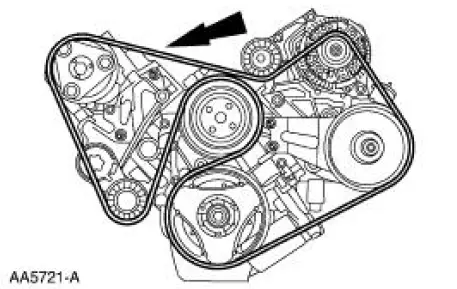

11. CAUTION: The crankshaft journals must be protected from damage when installing the crankshaft.

Position the crankshaft.

CAUTION: The main bearings are precision selective fit. Inspect the bearing clearance.

12. NOTE: If the rear main bearing cap is not secured within four minutes, the sealant must be removed and the sealing area cleaned with metal surface cleaner. Allow to dry until there is no sign of wetness, or four minutes, whichever is longer. Failure to follow this procedure can cause future oil leakage.

Clean the rear main bearing cap sealing area with metal surface cleaner. Apply silicone gasket and sealant to the rear main bearing cap-to-cylinder block parting line.

13. Install the main bearing caps. Tighten the bolts in two stages:

- Stage 1: Tighten to 50 Nm (37 lb-ft).

- Stage 2: Rotate an additional 120 degrees.

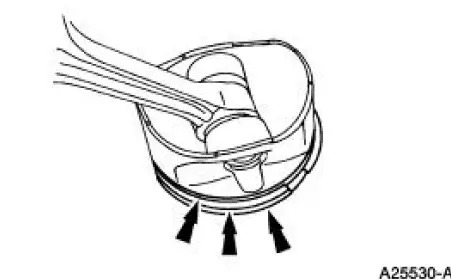

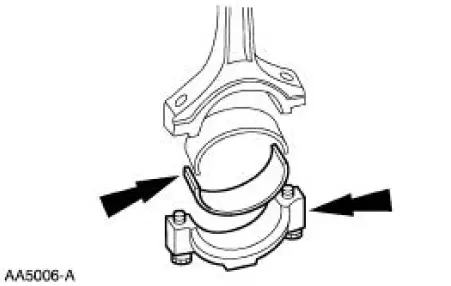

14. Compress the piston rings.

15. CAUTION: Inspect the piston clearance.

CAUTION: Do not damage the cylinder wall with the sharp edges of the connecting rod.

Install the piston with the arrow on the piston face pointing toward the front of the engine.

16. CAUTION: Inspect the connecting rod bearing clearance.

CAUTION: The connecting rod cap will fit only one way.

Position the connecting lower rod bearing and the connecting rod cap on the connecting rod and the crankshaft journal.

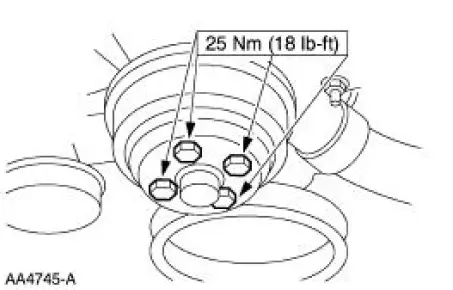

17. Install the rod caps. Tighten the bolts in three stages:

- Stage 1: Tighten to 25 Nm (18 lb-ft).

- Stage 2: Tighten to 45 Nm (33 lb-ft).

- Stage 3: Tighten an additional 105 degrees.

18. Install the remaining pistons and the connecting rods.

19. Install the oil pan bridge and baffle assembly.

20. Using a new gasket, install the oil pump screen cover and tube.

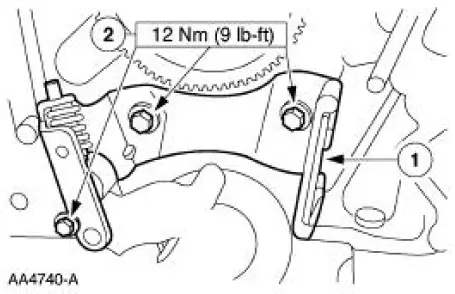

21. Install the timing chain tensioner.

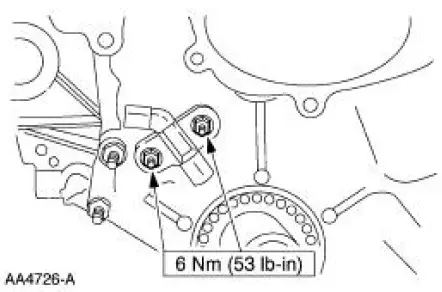

1. Position the timing chain tensioner.

2. Install the bolts.

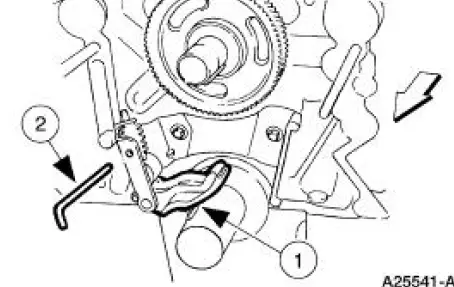

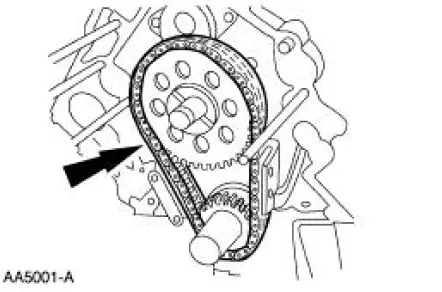

22. Retract the tensioner pad retracting mechanism.

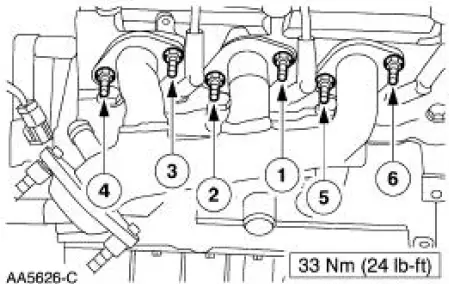

1. Compress the tensioner pad retracting mechanism.

2. Insert a retaining pin.

23. Rotate the crankshaft so the number one piston is at top dead center (TDC) and the key is at the 12 o'clock position.

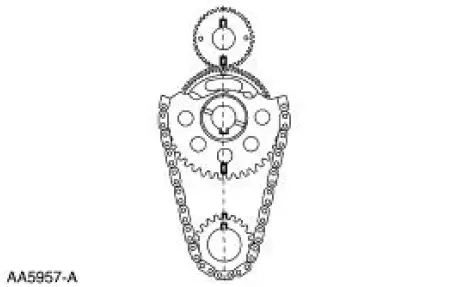

24. Turn the camshaft sprocket so that the keyway is on the bottom of the camshaft.

25. Install the timing chain, the camshaft sprocket and the crankshaft sprocket as an assembly.

26. Make sure the timing marks and the keyways are aligned.

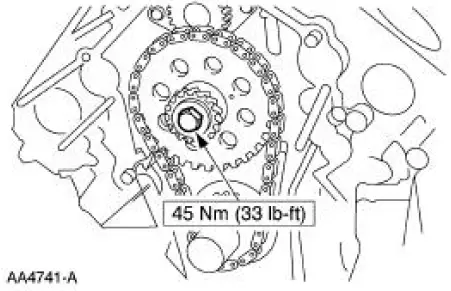

27. Install the camshaft position sensor drive gear and retaining bolt.

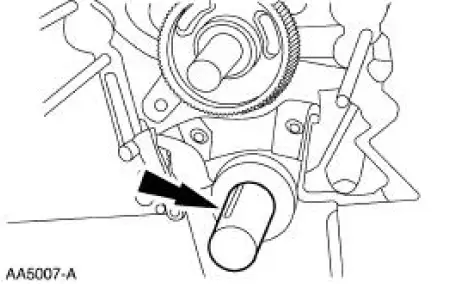

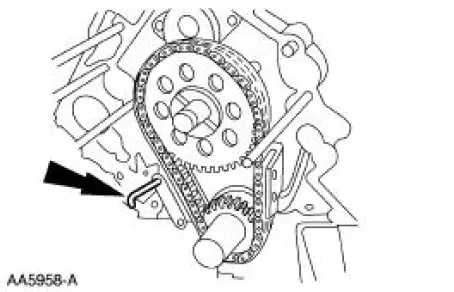

28. Remove the retaining pin.

CAUTION: The components removed should be marked for location. Make sure the used parts are installed in the correct location.

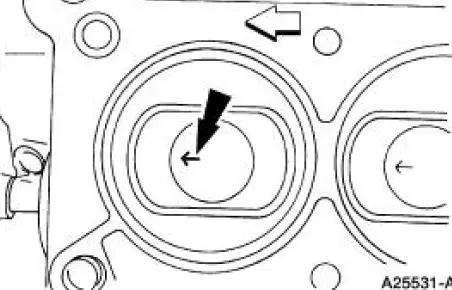

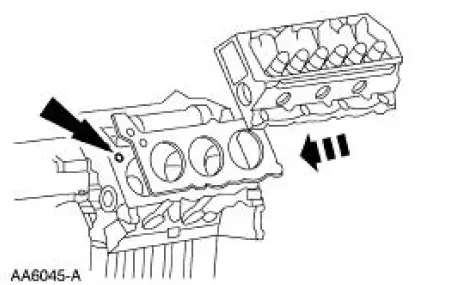

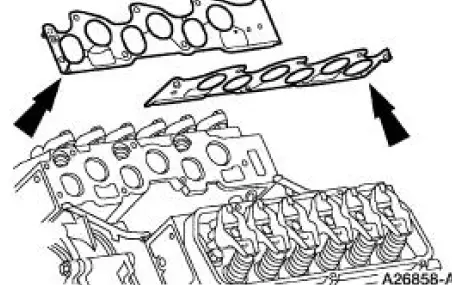

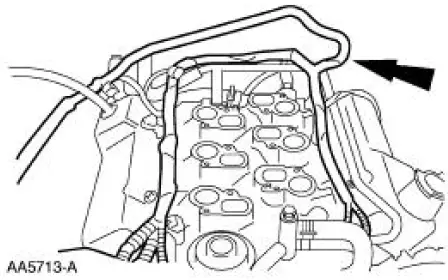

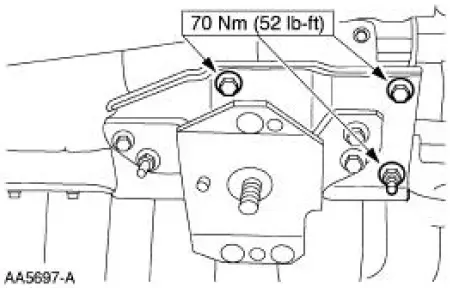

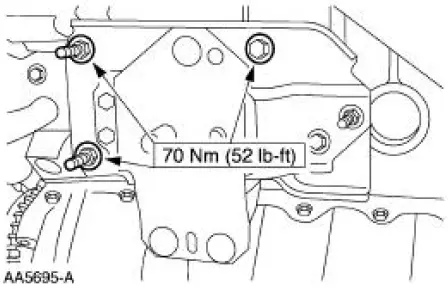

29. NOTE: Install the new cylinder head gaskets with the small hole to the front of the engine.

Using new gaskets, install the RH and the LH cylinder heads.

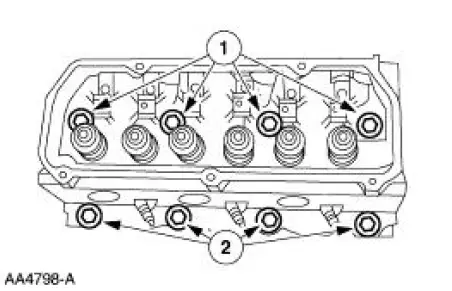

30. CAUTION: Always use new bolts.

NOTE: Lubricate the bolts with clean engine oil prior to installation.

Position the new bolts.

1. Position the new long bolts.

2. Position the new short bolts.

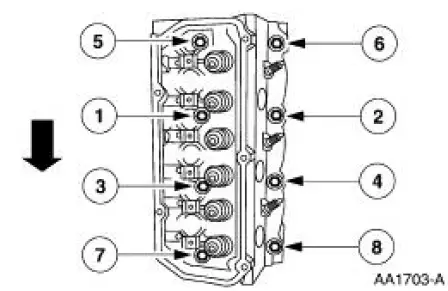

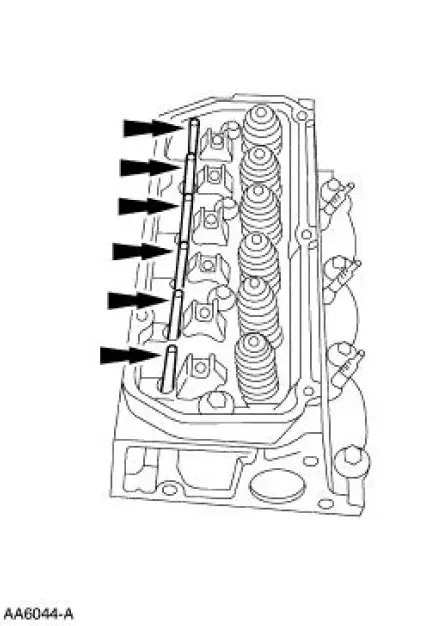

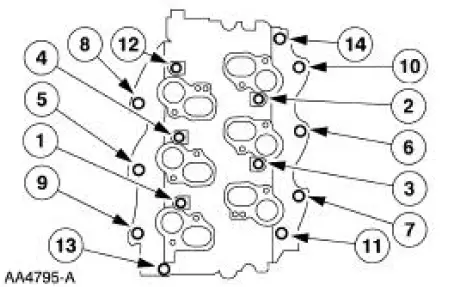

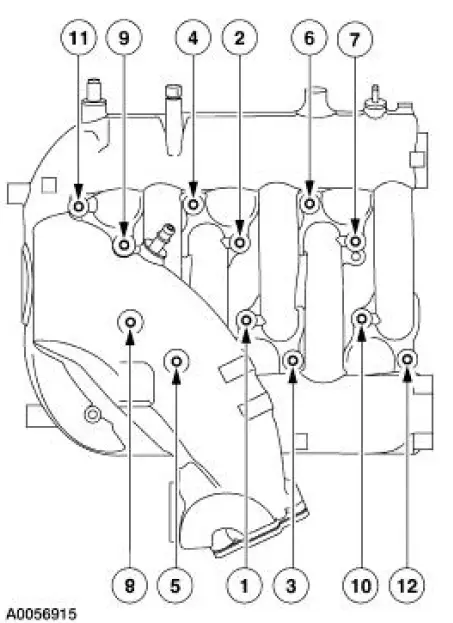

31. Tighten the bolts in three stages in the sequence shown:

- Stage 1: Tighten to 20 Nm (15 lb-ft).

- Stage 2: Tighten to 40 Nm (30 lb-ft).

- Stage 3: Tighten to 50 Nm (37 lb-ft).

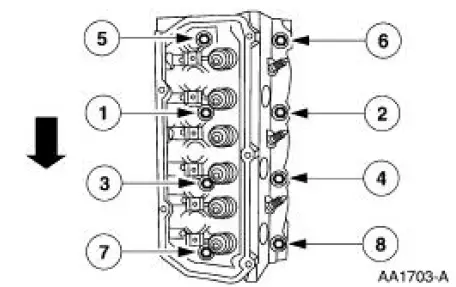

32. CAUTION: Do not loosen all of the bolts at one time. Each bolt must be loosened and tightened prior to working on the next bolt in the sequence.

Tighten the bolts in four stages in the sequence shown: short bolts numbered 2, 4, 6 and 8:

- Stage 1: Tighten to 25 Nm (18 lb-ft).

- Stage 2: Tighten an additional 180 degrees.

Long bolts numbered 1, 3, 5 and 7:

- Stage 3: Tighten to 45 Nm (33 lb-ft).

- Stage 4: Tighten an additional 180 degrees.

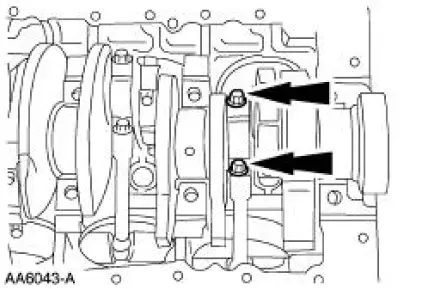

33. NOTE: Lubricate the valve tappets with clean engine oil prior to installing.

Install the valve tappets.

- Install the valve tappets.

- Install the tappet guide plates and retainers.

- Install the bolts.

34. NOTE: Lubricate the push rods with clean engine oil prior to installation.

Install the 12 push rods.

35. Install the 12 rocker arms. For additional information, refer to Rocker Arm in this section.

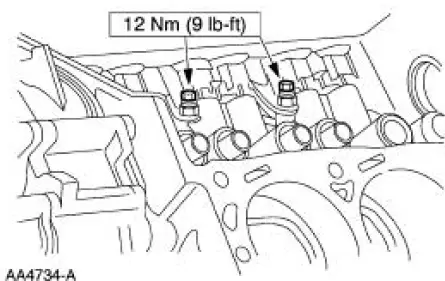

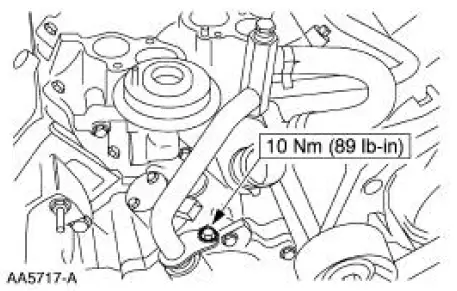

36. NOTE: Use pipe sealant with Teflon on studs No. 4 and 6, and bolt No. 12.

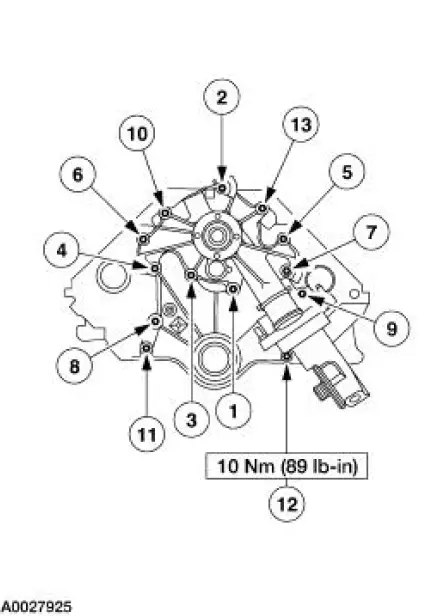

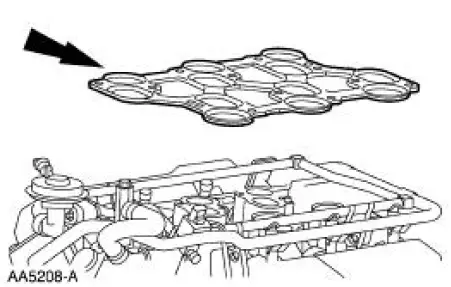

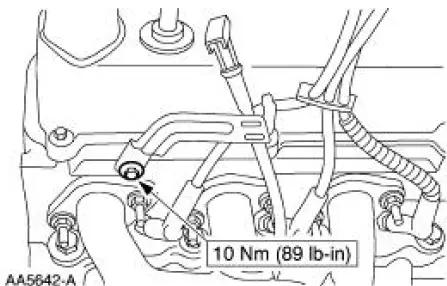

Using a new gasket, install the engine front cover. Tighten the nuts and the bolts in the sequence shown.

- Install a 135.5 mm (5.42 in) stud at location No. 5 and tighten to 7 Nm (62 lb-in).

- Install a 137 mm (5.48 in) stud at locations No. 4, 6, 7 and 10, and tighten to 7 Nm (62 lbin).

- Using a new gasket, install the water pump.

- Tighten bolt No. 12 to 10 Nm (89 lb-in). All other nuts and bolts are to be tightened to 28 Nm (21 lb-ft).

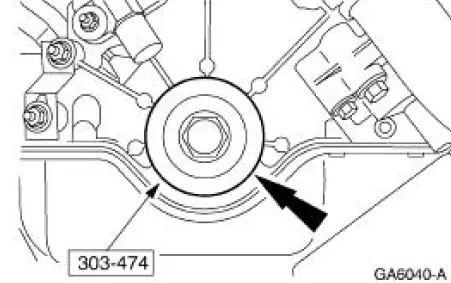

37. NOTE: Lubricate the parts with clean engine oil before assembly.

Using the special tool, install the front crankshaft seal.

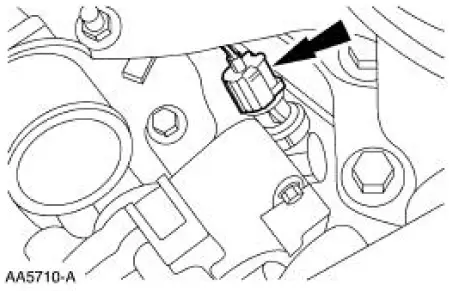

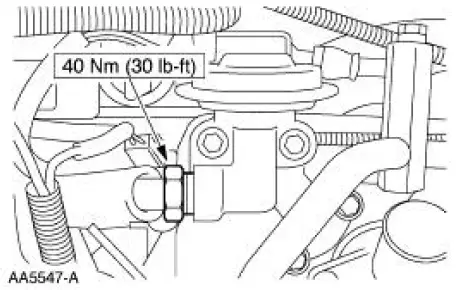

38. Install the crankshaft position sensor.

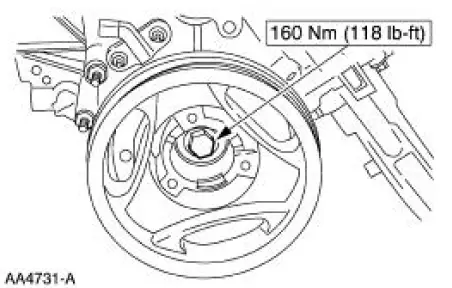

39. Apply a bead of silicone gasket and sealant to the keyway in the crankshaft damper. Using the special tool, position and install the crankshaft damper.

40. Install the crankshaft pulley bolt.

41. Install the camshaft synchronizer. 42. Install the water pump pulley and the retaining bolts.

43. NOTE: If the oil pan is not secured within four minutes, the sealant must be removed and the sealing area cleaned with metal surface cleaner. Allow to dry until there is no sign of wetness, or four minutes, whichever is longer. Failure to follow this procedure can cause future oil leakage.

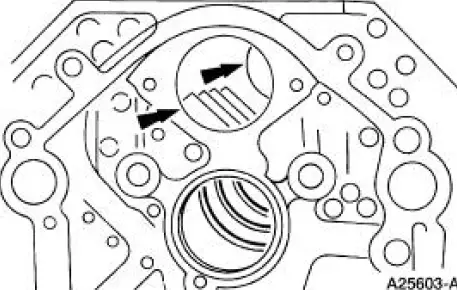

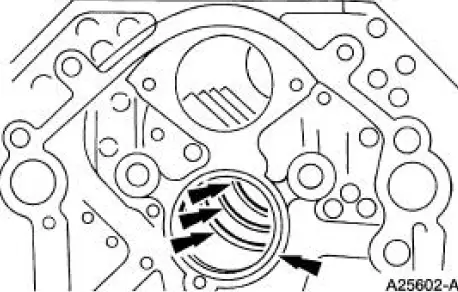

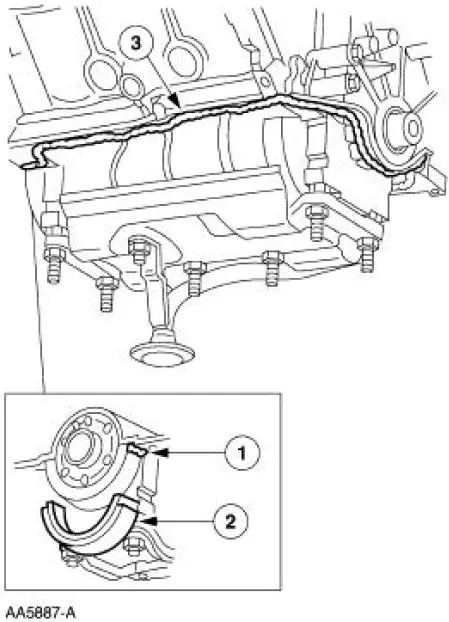

Clean and apply the sealant to the oil pan sealing areas shown and install the oil pan rear seal.

1. Apply silicone gasket and sealant to the rear main bearing cap.

2. Install the oil pan rear seal.

3. Clean the oil pan mating surfaces with metal surface cleaner and apply silicone gasket and sealant to the oil pan mating surface.

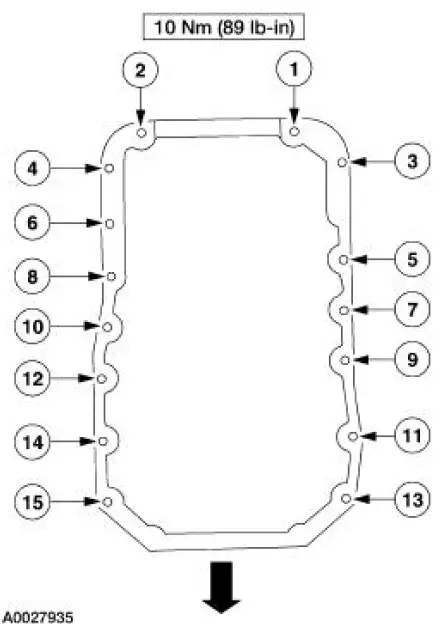

44. Tighten the oil pan bolts in the sequence shown.

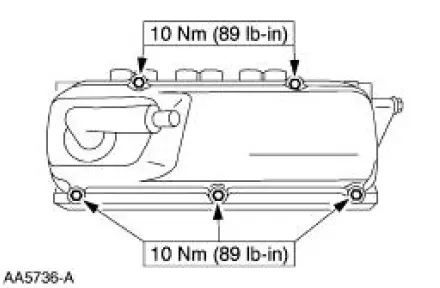

45. Install the RH valve cover.

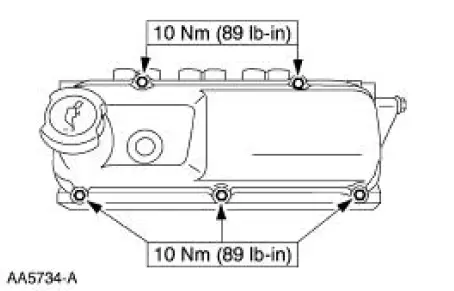

46. Install the LH valve cover.

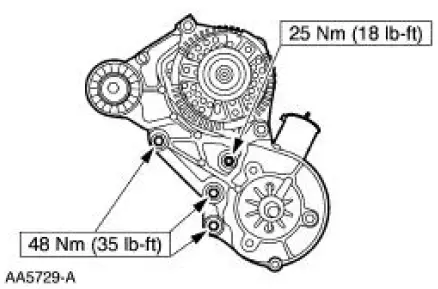

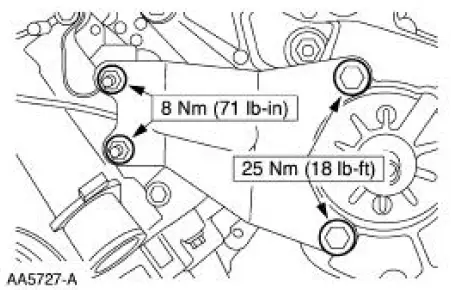

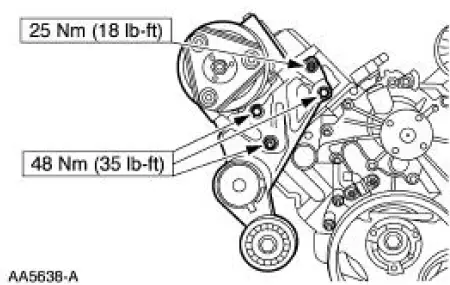

47. Install the generator mounting bracket.

48. Install the power steering pump bracket.

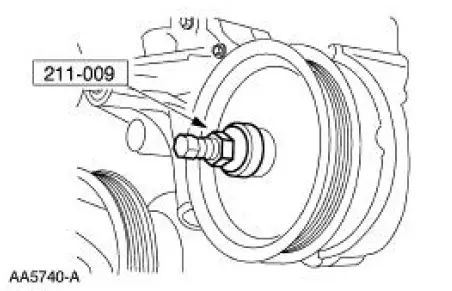

49. Using the special tool, install the power steering pump pulley.

50. Install the A/C compressor bracket and the bolts.

51. Install the accessory drive belt.

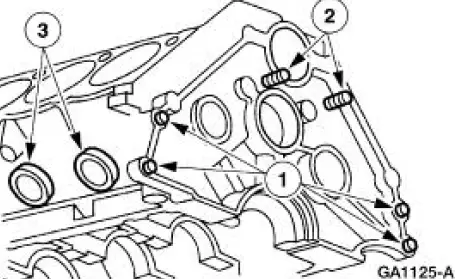

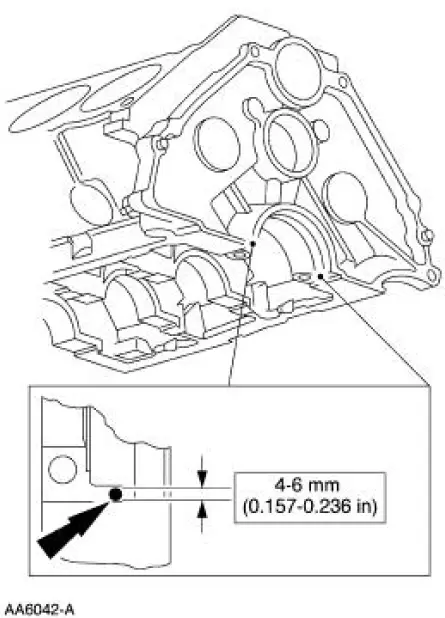

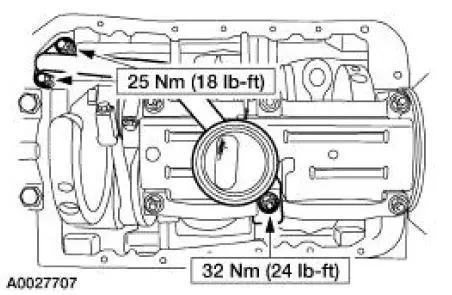

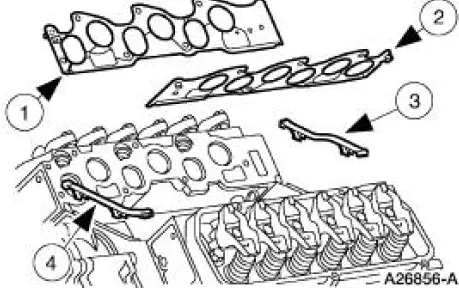

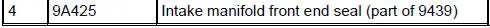

52. Refer to the illustration for intake manifold sealing components.

53. NOTE: If the lower intake manifold is not secured within four minutes, the sealant must be removed and the sealing area cleaned with metal surface cleaner. Allow to dry until there is no sign of wetness, or four minutes, whichever is longer. Failure to follow this procedure can cause future oil leakage.

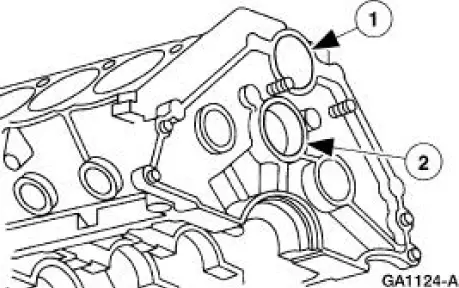

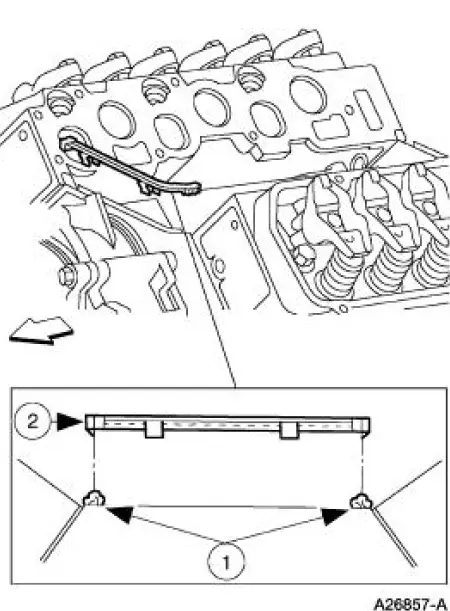

Install the lower intake manifold front and rear end seals.

1. Apply a bead of silicone gasket and sealant to the intake manifold front and rear end seal mounting points as indicated.

2. Install the lower intake manifold front and rear end seals.

54. Install the intake manifold gaskets.

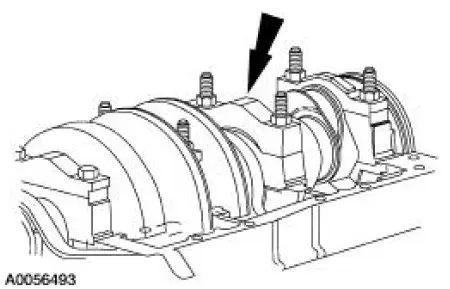

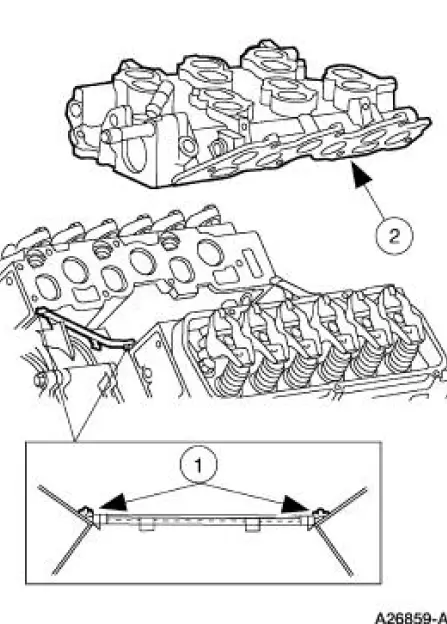

55. NOTE: If the lower intake manifold is not secured within four minutes, the sealant must be removed and the sealing area cleaned with metal surface cleaner. Allow to dry until there is no sign of wetness, or four minutes, whichever is longer. Failure to follow this procedure can cause future oil leakage.

Position the lower intake manifold.

1. Apply a bead of silicone gasket and sealant to the lower intake manifold mounting at the points indicated.

2. Position the lower intake manifold.

56. Install the lower intake manifold bolts.

- Install the six long bolts.

- Install the eight short bolts.

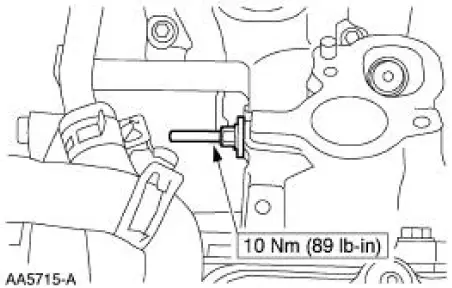

57. Tighten the bolts in two stages in the sequence shown.

1. Stage 1: Tighten to 5 Nm (44 lb-in).

2. Stage 2: Tighten to 10 Nm (89 lb-in).

58. Install the heater water outlet tube.

59. Install the stud bolt.

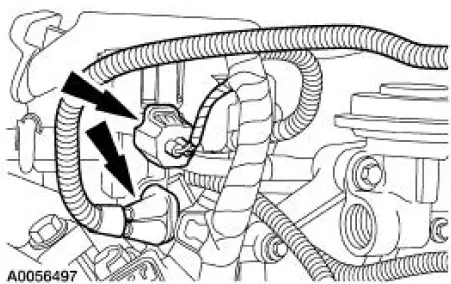

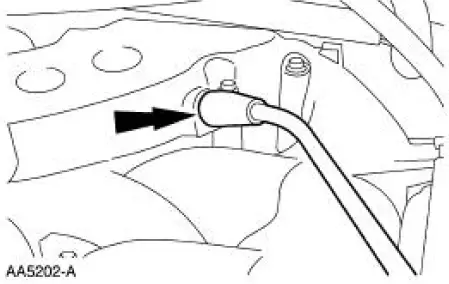

60. Position the engine wire harness.

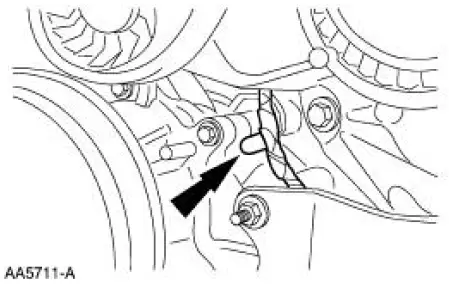

61. Connect the crankshaft position sensor electrical connector.

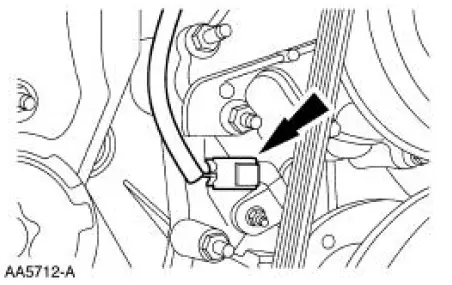

62. Install the pin-type retainer.

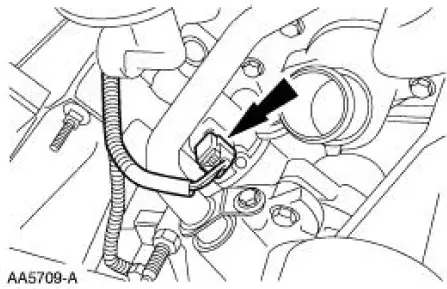

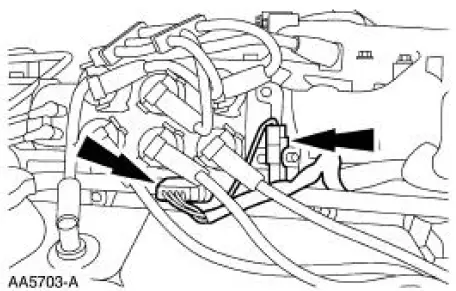

63. Connect the engine oil pressure sender electrical connector.

64. Connect the camshaft position (CMP) sensor electrical connector.

65. Connect the cylinder head temperature (CHT) sensor.

66. Install the fuel injectors and the fuel injection supply manifold as an assembly.

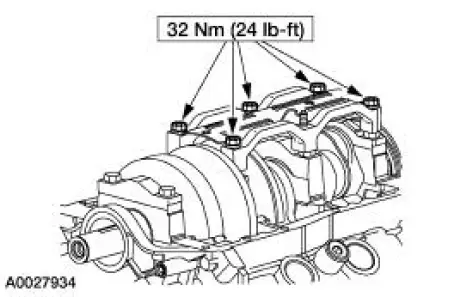

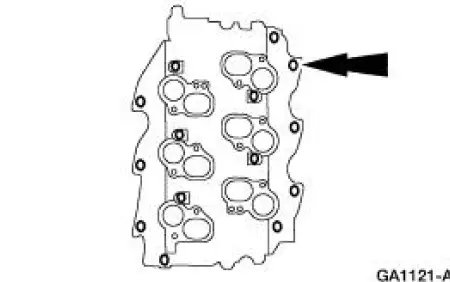

67. Install a new upper intake manifold gasket.

68. NOTE: Refer to the location note made during removal and make sure the bolts are installed in the correct location.

Install the upper intake manifold. Tighten the bolts in two stages in the sequence shown.

- Stage 1: Tighten to 10 Nm (89 lb-in).

- Stage 2: Rotate an additional 90 degrees.

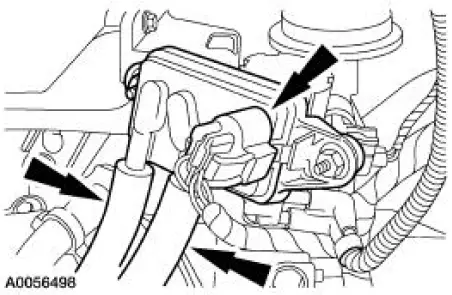

69. Connect the exhaust gas recirculation (EGR) vacuum regulator solenoid electrical and vacuum connections.

70. Connect the differential pressure feedback EGR system electrical and vacuum connections.

71. Connect the vacuum hoses.

72. Install the positive crankcase ventilation (PCV) tube.

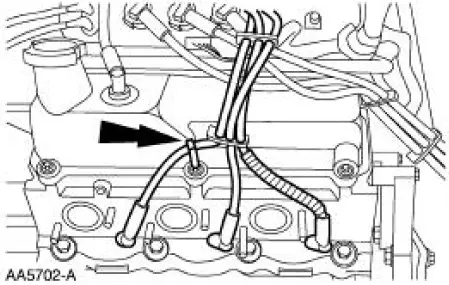

73. Connect the ignition coil and the radio interference capacitor electrical connectors.

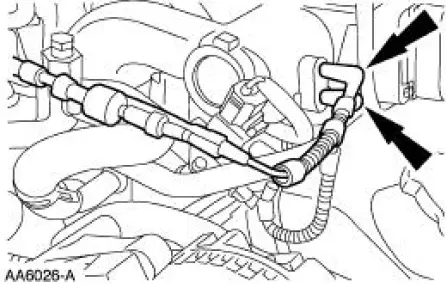

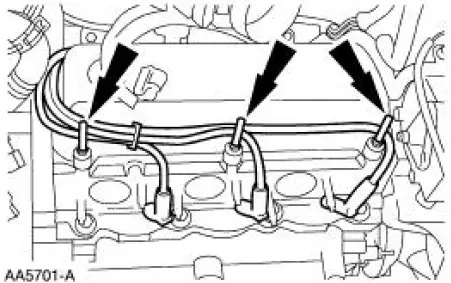

74. Position and connect the LH spark plug wires.

75. Position and connect the RH spark plug wires.

76. Connect the idle air control (IAC) valve and the throttle position (TP) sensor electrical connectors.

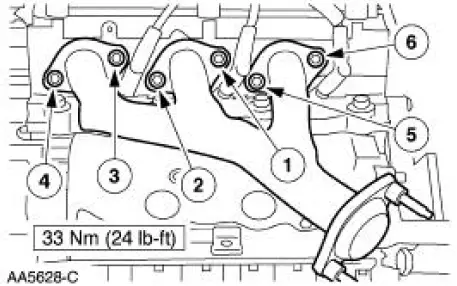

77. Install the RH exhaust manifold.

- Install a new exhaust manifold gasket.

- Install the exhaust manifold.

- Tighten the nuts in the sequence shown.

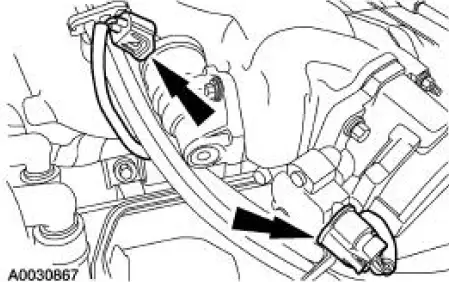

78. Install the exhaust gas recirculation (EGR) tube.

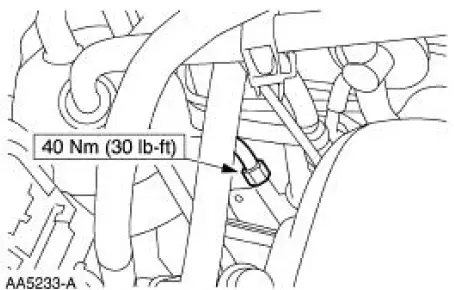

79. Connect the EGR valve nut.

80. Using a new gasket, install the LH exhaust manifold. Tighten the nuts in the sequence shown.

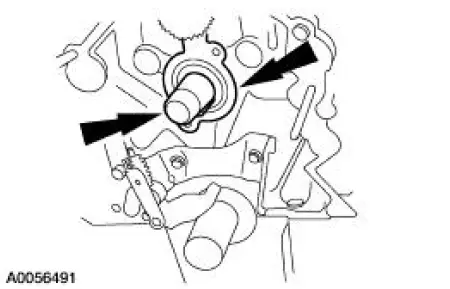

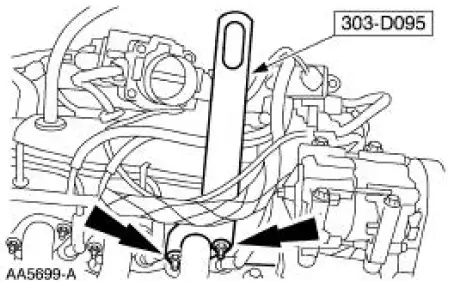

81. NOTE: Install a new O-ring seal.

Install the oil level indicator and tube and retaining bolt.

82. Install the special tool.

83. Install the special tool.

84. Install the RH engine support insulator.

85. Install the LH engine support insulator.

86. Remove the engine from the stand.

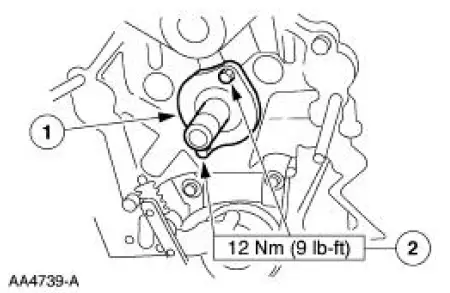

87. NOTE: Lubricate the crankshaft rear seal lips with clean engine oil prior to installation.

Assemble the special tools and the crankshaft rear seal.

88. Install the special tools on the rear of the crankshaft.

89. Install the crankshaft rear seal. Tighten the center jack screw (303-S560) until the spacer (303- 561) contacts the engine block.

Piston

Piston

Special Tool(s)

Piston Pin Tool or equivalent

303-D034 (D81L-6135-A)

Material

Item

Specification

SAE 5W-20 Premium Synthetic

Blend Motor Oil

XO-5W20-QSP or equivalent

...

Engine (Installation)

Engine (Installation)

Special Tool(s)

Heavy Duty Floor Crane

014-00071 or equivalent

Spreader Bar

303-D089 (D93P-6001-A3) or

equivalent

Material

Item

Specification

SAE 5W-20 Pre ...

Other materials:

Speakers

Torque Specifications

Speakers

NOTE: Premium sound speakers (18808) are labeled with either 6

OHMS or 8 OHMS.

The coupe has a four-speaker system, with two door-mounted

speakers and two in the package

tray panel (46506).

On the convertibl ...

Charging System (Diagnosis and Testing)

Refer to Wiring Diagrams Cell 12 , Charging System for schematic and

connector information.

Special Tool(s)

73III Automotive Meter

105-R0057 or equivalent

SABRE Premium Battery and

Electrical System Tester

010-00736 or equival ...

Exhaust Gas Recirculation (EGR) Valve - Cobra

Removal and Installation

1. Disconnect the accelerator cable and the speed control cable.

2. Remove the accelerator cable bracket bolts.

3. Release the clip and position the accelerator cable bracket and the cables

aside.

4. Disconnect the electrical c ...