Ford Mustang (1999-2004) Service Manual: Exhaust Manifold - Inspection

Special Tool(s)

|

|

Straight Edge 303-D039 (D83L-4201-A) or equivalent |

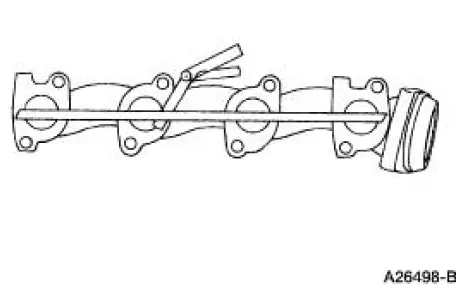

1. Place a straight edge across the exhaust manifold flanges and check for warping with a feeler gauge.

Bearing -Inspection

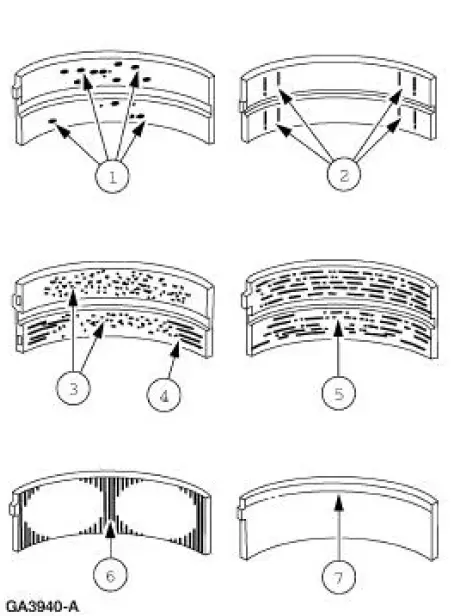

1. Inspect bearings for the following defects. Possible causes are shown:

1. Cratering - fatigue failure.

2. Spot polishing - incorrect seating.

3. Imbedded dirt engine oil.

4. Scratching - dirty engine oil.

5. Base exposed - poor lubrication.

6. Both edges worn - journal damaged.

7. One edge worn - journal tapered or bearing not seated.

Spark Plug - Inspection

Spark Plug - Inspection

1. Inspect the spark plug for a bridged gap.

Check for deposit build-up closing the gap between the electrodes.

Deposits are caused

by oil or carbon fouling.

Clean the spark plug.

2. Ch ...

Engine - 3.8L

Engine - 3.8L

General Specifications

a - 20-200 seconds to leakdown 3.18 mm (0.125 in) with 225 Newtons (50

pounds) load and tappet filled

with leak-down fluid.

Torque Specifications

a - Refer to th ...

Other materials:

Navigation controls

Type 1

WARNING: Driving while distracted can result in loss of vehicle

control, crash and injury. We strongly recommend that you use

extreme caution when using any device that may take your focus off

the road. Your primary responsibility is the safe operation ...

Exhaust System Neutralizing

WARNING: Exhaust gases contain carbon monoxide, which is harmful to

health and

potentially lethal. Repair exhaust system leaks immediately. Never operate the

engine in an

enclosed area.

WARNING: Exhaust system components are hot.

NOTE: Neutralize the exhau ...

Trim Panel - Door

Removal

All vehicles

1. CAUTION: Use a shop towel or similar material between the

tool and the front door

trim panel or damage to the front door trim panel may occur.

Position the window regulator switch plate (14527) aside.

1. Pull at the ser ...