Ford Mustang (1999-2004) Service Manual: Installation

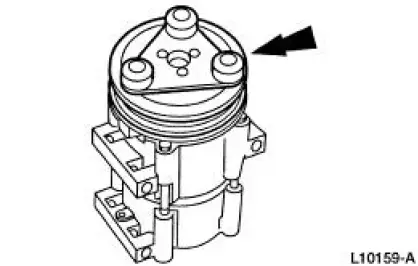

1. Clean the A/C disc and field coil and pulley mounting surfaces.

2. CAUTION: Do not use air tools. The A/C clutch field coil can be easily damaged.

Install the A/C clutch field coil.

1. Place the A/C clutch field coil on the A/C compressor with the A/C clutch field coil electrical connector correctly positioned.

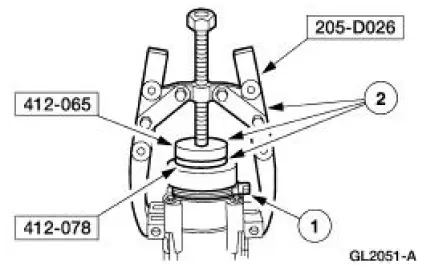

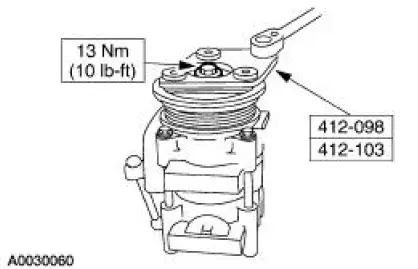

2. Using the special tools, install the A/C field coil.

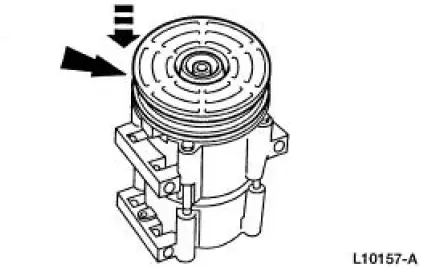

3. NOTE: The A/C clutch pulley is a tight fit on the A/C compressor head. It must be correctly aligned during installation.

Install the A/C clutch pulley.

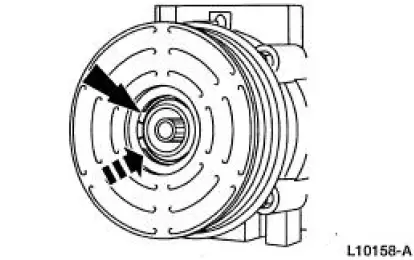

4. Install the pulley snap ring with the bevel side out.

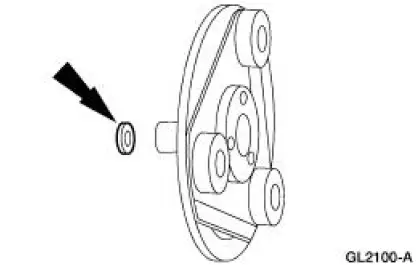

5. Place one nominal thickness A/C clutch hub spacer inside the clutch hub spline opening.

6. Install the A/C clutch.

7. Using the special tool, install the A/C disc and hub assembly retaining bolt.

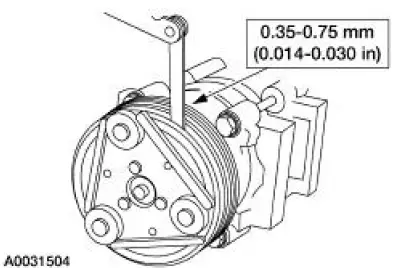

8. Measure and adjust the clutch air gap by removing or adding A/C clutch hub spacers.

9. Install the A/C compressor. For additional information, refer to Air Conditioning (A/C) Compressor-3.8L or Air Conditioning (A/C) Compressor-4.6L in this section.

Removal

Removal

1. Remove the A/C compressor (19703). For additional information, refer to

Air Conditioning (A/C)

Compressor-3.8L or Air Conditioning (A/C) Compressor-4.6L in this section.

2. Remove the bolt.

1. ...

Air Conditioning (A/C) Compressor Shaft Seal

Air Conditioning (A/C) Compressor Shaft Seal

Special Tool(s)

Holding Fixture, Compressor

Clutch (3.8L vehicles)

412-098 (T94P-19703-AH)

Holding Fixture, Compressor

Clutch (4.6L vehicles)

412-103 (T95L-19703-AH)

...

Other materials:

Generator - 3.8L

Removal and Installation

1. Disconnect the battery (10655). For additional information, refer

to Section.

2. Relieve the accessory drive belt (8620) tension and remove the belt

from the generator pulley.

Leave the belt in place for reinstallation ...

Component Tests

Driveline Vibration

An analysis of driveline vibration can also be conducted using the Vibration

Analyzer; follow the

manufacturer's directions.

Driveline vibration exhibits a higher frequency and lower amplitude than does

high-speed shake.

Driveline vibra ...

Pinpoint Test J: LFC 34/DTC B1934 - Driver Air Bag Circuit Resistance Low

Normal Operation

The restraints control module (RCM) monitors the resistance of the driver

air bag ignitor by measuring

the resistance between pins 3 and 4. If the RCM detects low resistance

between these pins, it will

store a diagnostic trouble code (D ...