Ford Mustang (1999-2004) Service Manual: Installation

1. Inspect the rear axle pinion flange seal journal for rust, nicks, and scratches prior to installing the flange. Polish the seal journal with fine crocus cloth, if necessary.

2. Lubricate the rear axle pinion flange splines.

- Use SAE 75W-140 High Performance Rear Axle Lubricant F1TZ-19580-B or equivalent meeting Ford specification WSL-M2C192-A.

3. NOTE: Disregard the index marks if installing a new rear axle pinion flange.

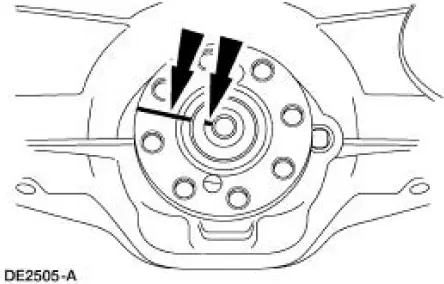

Position the rear axle pinion flange.

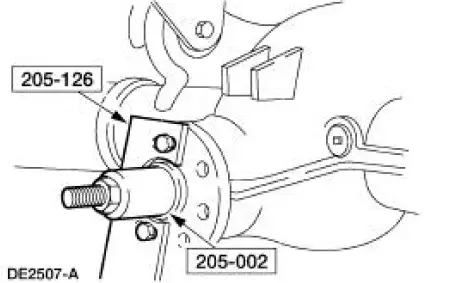

4. Using the special tools, install the rear axle pinion flange.

5. CAUTION: Do not under any circumstance loosen the nut to reduce preload. If it is necessary to reduce preload, install a new differential drive pinion collapsible spacer (4662) and nut.

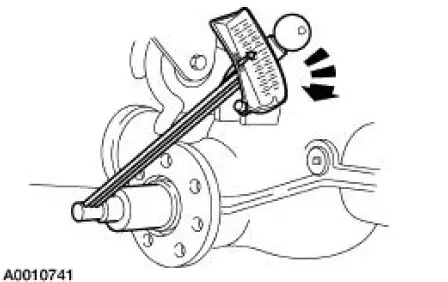

Tighten the nut to set the preload.

- Rotate the pinion occasionally to make sure the pinion bearings (4630) (4621) seat correctly. Take frequent pinion bearing torque preload readings by rotating the drive pinion gear with a Nm (inch/pound) torque wrench.

- If the preload recorded prior to disassembly is lower than the specification for used bearings, then tighten the nut to specification. If the preload recorded prior to disassembly is higher than the specification for used bearings, then tighten the nut to the original reading as recorded.

- Refer to the torque specification for used pinion bearings in the Specifications portion of this section.

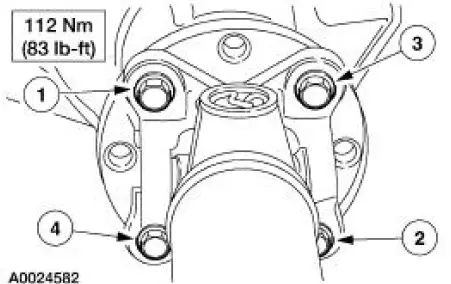

6. CAUTION: Align the index-marks.

CAUTION: Install the driveshaft with new bolts. If new bolts are not available, apply Threadlock and Sealer EOAZ-19554-AA or equivalent meeting Ford specification WSKM2G351- A5 to the threads of the original bolts.

CAUTION: The driveshaft centering socket yoke fits tightly on the rear axle pinion flange pilot. To make sure that the yoke seats squarely on the flange, tighten the bolts evenly in a cross pattern as shown.

Connect the driveshaft.

7. Install the rear brake calipers.

8. Install the rear wheel and tire assemblies.

9. Lower the vehicle.

Removal

Removal

1. Raise and support the vehicle.

2. Remove the rear wheel and tire assemblies.

3. CAUTION: Remove the rear brake calipers to prevent drag during the

drive pinion

bearing preload adjustment.

CAU ...

Pinion Seal

Pinion Seal

Special Tool(s)

Installer, Drive Pinion Oil Seal

205-133 (T79P-4676-A)

Removal

1. Remove the pinion flange (4851). For additional information, refer to

Drive Pinion Flange in this

sec ...

Other materials:

Pinpoint Test F: LFC 16/DTC B1888 - Passenger Air Bag Circuit Shorted to

Ground

Normal Operation

The restraints control module (RCM) checks for passenger air bag circuit

shorts to ground by

monitoring the voltage of circuits 607 (LB/OG) and 616 (PK/BK) at pins 6 and

7. If the RCM detects a

short to ground on either of these pins, i ...

Removal

CAUTION: Suspension fasteners are critical parts because they affect

performance of vital

components and systems and their failure can result in major service expense. A

new part with

the same part number must be installed if installation becomes necessary. ...

System Flushing - CIII Power Steering Pump

WARNING: Do not mix oil types. Any mixture or any unapproved oil can

lead to seal

deterioration and leaks. A leak can ultimately cause loss of fluid, which can

result in a loss of

power steering assist.

1. Remove the fuel pump fuse from the battery junction ...