Ford Mustang (1999-2004) Service Manual: Installation

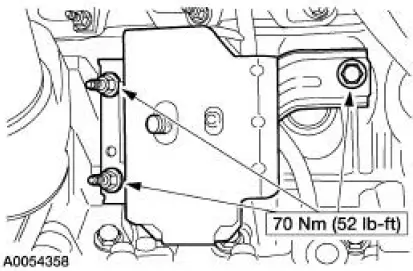

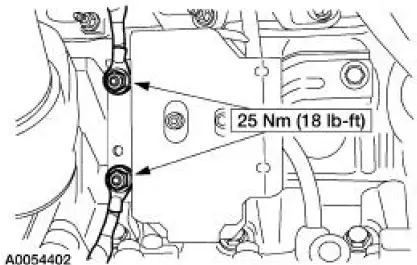

LH mount

1. Position the engine mount and install the bolt and studbolts.

2. Attach the ground cables and install the nuts.

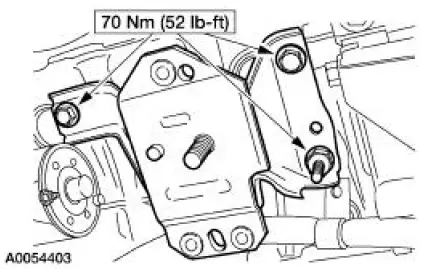

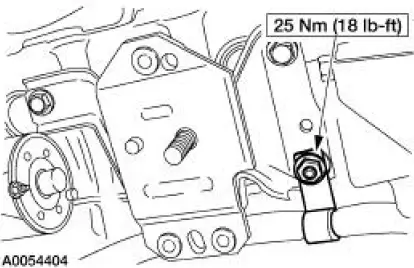

RH mount

3. Position the engine mount and install the bolts and studbolt.

4. Attach the wiring harness and install the nut.

Both mounts

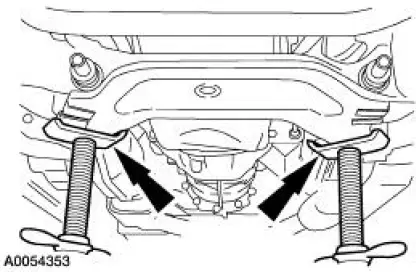

5. Using the jackstands, raise the subframe into position.

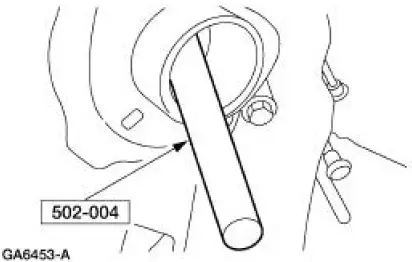

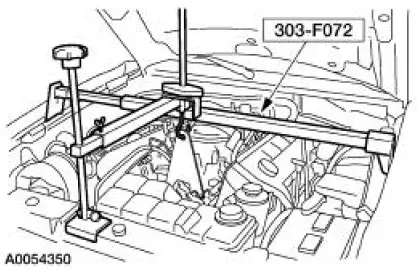

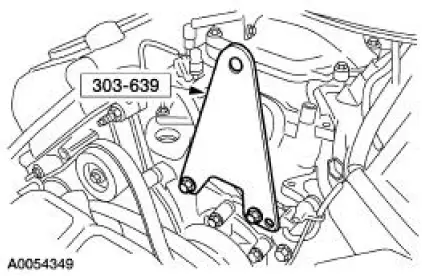

6. NOTE: RH shown, LH similar.

Using the special tool, align the subframe.

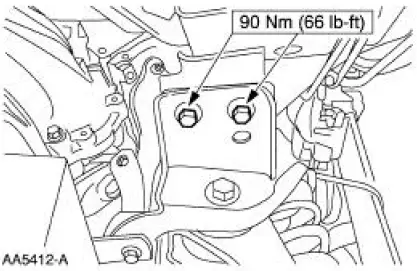

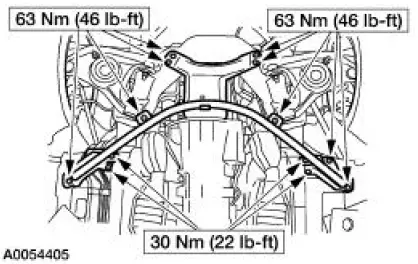

7. NOTE: RH shown, LH similar.

Install the four bolts.

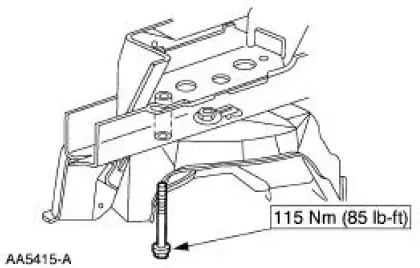

8. NOTE: RH shown, LH similar.

Install the four bolts.

9. Remove the jackstands.

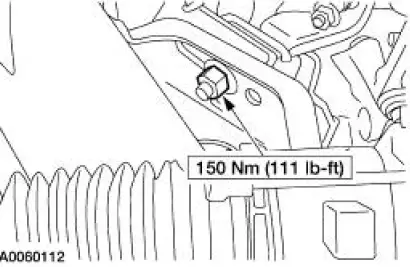

10. NOTE: RH shown, LH similar.

Install the two engine mount nuts.

11. Position the cross-brace support and install the 13 bolts.

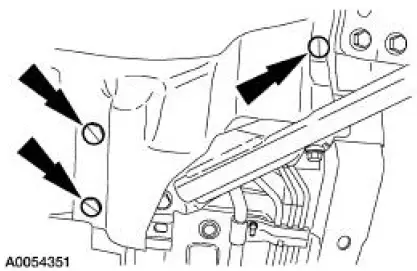

12. NOTE: RH shown, LH similar Install the six splash-shield pushpins.

13. Install the front springs. For additional information, refer to Section.

14. Remove the special tool.

15. Remove the special tool.

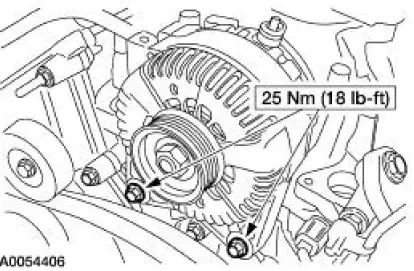

16. Position the generator and install the bolts.

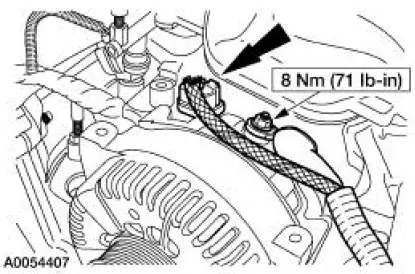

17. Connect the generator electrical connections.

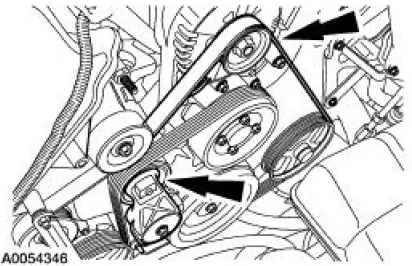

18. Rotate the drive belt tensioner clockwise and attach the drive belt to the generator pulley.

- Make sure the drive belt is routed correctly and is aligned correctly installed on each pulley.

19. Connect the battery ground cable. For additional information, refer to Section.

20. Install the coolant bypass tube. For additional information, refer to Section.

Removal

Removal

Both mounts

1. Disconnect the battery ground cable. For additional information, refer to

Section.

2. Remove the coolant bypass tube. For additional information, refer to Section.

3. Rotate the driv ...

Engine (Removal)

Engine (Removal)

Special Tool(s)

Lifting Bracket, Engine

303-D087 (D93P-6001-A1)

Lifting Bracket, Engine

303-D088 (D93P-6001-A2)

Spreader Bar

303-D089 (D93P-6001-A3)

Rem ...

Other materials:

Entertainment System - General Information

Audio System (Diagnosis and Testing)

Refer to Wiring Diagrams Cell 130 , Radio for schematic and connector

information.

Special Tool(s)

73III Automotive Meter

105-R0057 or equivalent

Inspection and Verification

1. Verify the customer con ...

Assembly

1. CAUTION: Before beginning assembly, carry out and inspect the

following:

When building up subassemblies and assembling the transmission, ALWAYS use new

gaskets and seals.

All fasteners must be tightened to the torque specification indicated. In

addition ...

Piston - Pin to Bore Diameter

1. WARNING: Cover the end of the pin bore with a hand or shop rag when

removing

the retainer ring, since it has a tendency to spring out. Wear eye protection.

NOTE: Piston and piston pins are a matched set and should not be

interchanged.

Measure the pisto ...