Ford Mustang (1999-2004) Service Manual: Installation

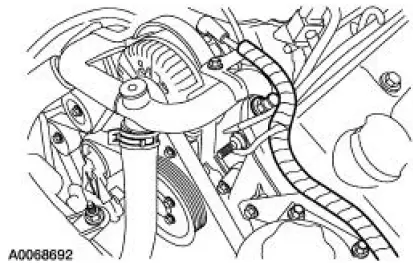

1. Position the wiring harness:

- Install the wiring harness retainer onto the LH valve cover stud bolt.

- Install the wiring harness retainer into the power steering reservoir.

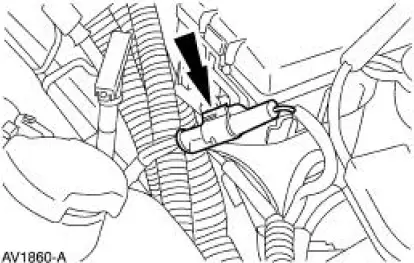

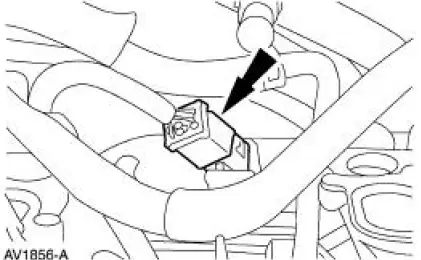

2. Connect the ECT sensor electrical connector.

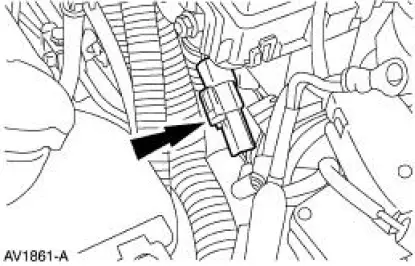

3. Connect the CMP sensor electrical connector.

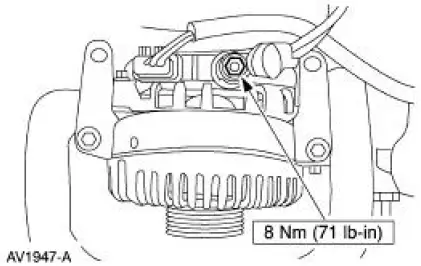

4. Connect the following generator electrical connectors:

- Battery power supply wire.

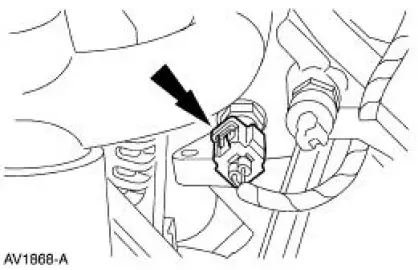

- Voltage regulator.

5. Connect the electrical connector.

6. Connect the electrical connector.

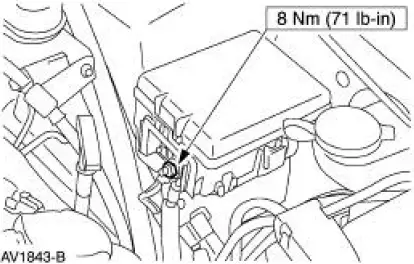

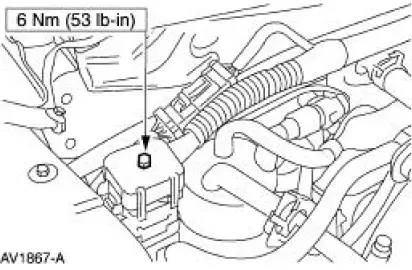

7. Install the battery supply wire to the power distribution box stud.

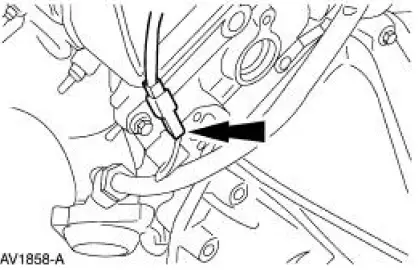

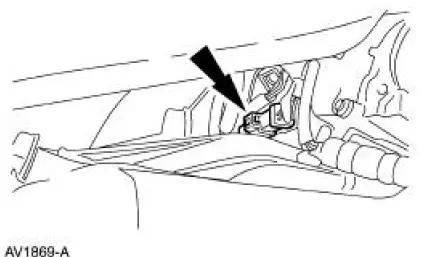

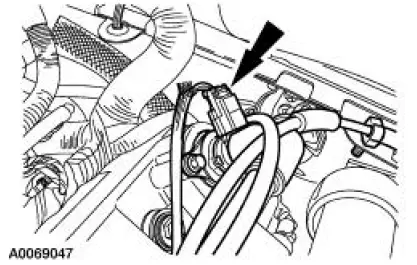

8. NOTE: LH side is shown, RH side is similar.

Connect the two radio ignition interference capacitor electrical connectors.

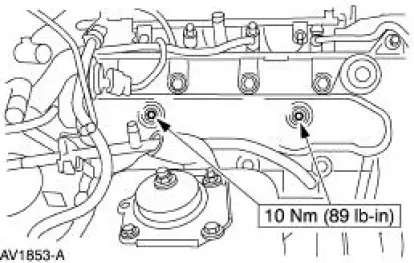

9. Connect the RH HO2S electrical connector.

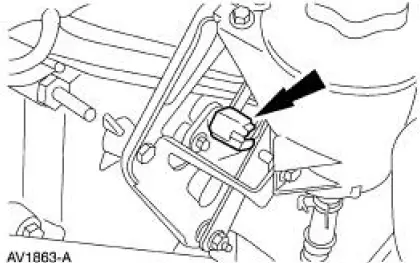

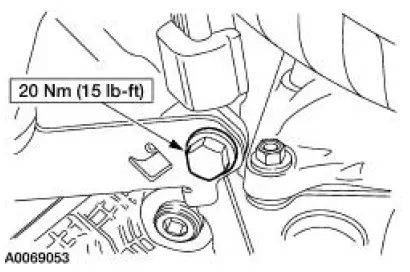

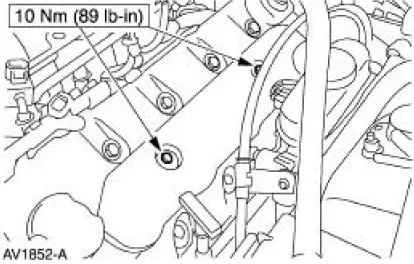

10. Install the wiring harness bracket bolt.

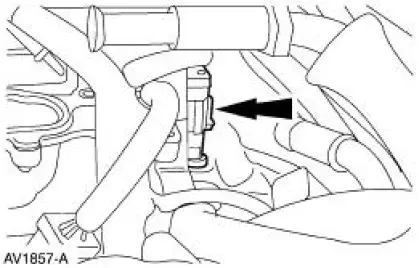

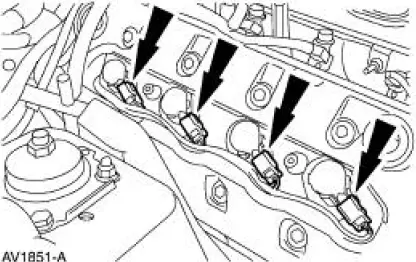

11. Connect the engine control jumper harness electrical connector.

12. Connect the transmission main control harness electrical connector.

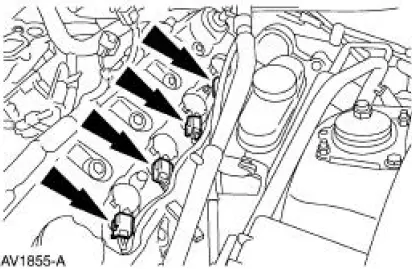

13. Connect the LH ignition coil electrical connectors.

14. Install the LH ignition coil cover and bolts.

15. Connect the heated positive crankcase ventilation (PCV) vlave electrical connector.

16. Connect the RH ignition coil electrical connectors.

17. Install the RH ignition coil cover and bolts.

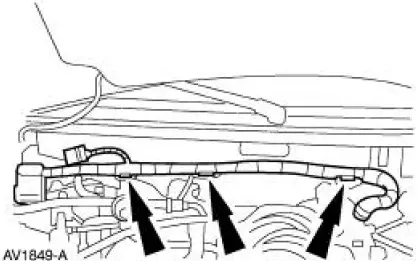

18. Install the wiring harness retainers into the dash panel.

19. Connect the following connectors:

- The 42 pin engine bulkhead electrical connector.

- The 16 pin electrical connector.

20. Install the upper intake manifold. For additional information, refer to Section.

21. NOTE: When the battery is disconnected and reconnected, some abnormal drive symptoms may occur while the vehicle relearns its adaptive strategy. The vehicle may need to be driven 16 km (10 mi) or more to relearn the strategy.

Connect the battery ground cable. For additional information, refer to Section.

Removal

Removal

WARNING: Do not smoke or carry lighted tobacco or open flame of any

type when

working on or near any fuel related components. Highly flammable mixtures are

always present

and can ignite. Failure to ...

Supply Manifold

Supply Manifold

Removal

WARNING: Do not smoke or carry lighted tobacco or open flame of any

type when

working on or near any fuel related components. Highly flammable mixtures are

always present

and can ignite. Fai ...

Other materials:

Coupling

Removal and Installation

1. CAUTION: Do not allow the steering column shaft to rotate while

intermediate shaft

is disconnected or damage to the clockspring can result. If there is evidence

that the

steering column shaft has rotated the clockspring must be re ...

Evaporator Core Housing

Material

Item

Specification

PAG Compressor Oil (R-134a

Systems)

F7AZ-19589-DA (Motorcraft

YN-12-C)

WSH-M1C231-

B

MERPOL

NA

ESE-M99B144-

B

Removal

NOTE: The evaporator core is not separately serviceable, it is

serviced onl ...

Disassembly

1. NOTE: The index mark on the output shaft must be aligned with the

index mark on the output

shaft ring gear during the assembly procedure.

Remove the ring gear snap ring.

2. Separate the ring gear and output shaft.

3. Remove the three output shaft seal ...