Ford Mustang (1999-2004) Service Manual: Lead Terminal Repair

Special Tool(s)

|

Heat Gun 107-R0300 or equivalent |

Material

| Item | Specification |

| Rear Window Defroster Repair D8AZ-19562-AA | WSB-M4J58-B |

1. NOTE: The rear window glass must be at room temperature at the time of the repair.

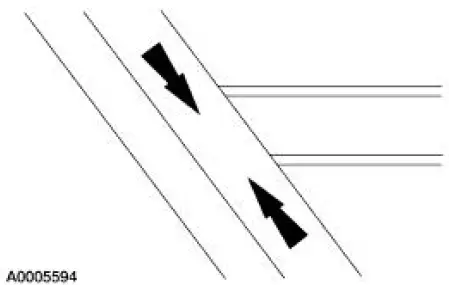

Clean the bus bar in the area to be repaired with steel wool (3/0 to 4/0 grade).

2. NOTE: Allow 10 minutes of drying time between the coats.

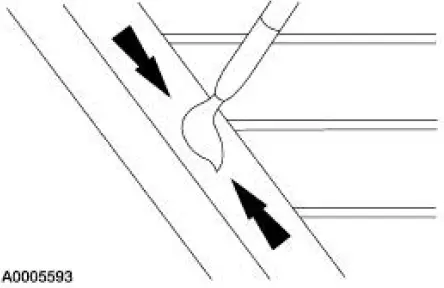

Apply three coats of rear window defroster repair to the surface.

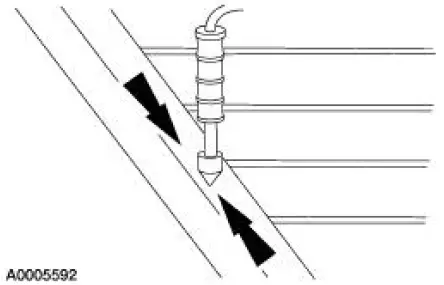

3. CAUTION: Do not overheat the rear window glass or damage to the rear window glass may occur.

Tin the bus bar repair area with solder.

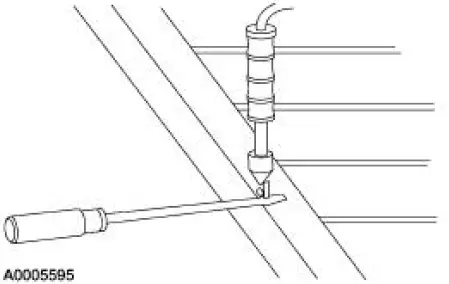

4. CAUTION: To prevent overheating the rear window glass, remove the soldering gun as soon as the solder flows.

Preheat the rear window glass in the area to be repaired using the special tool and solder the terminal to the bus bar.

5. NOTE: Turn the heated rear window switch ON for five minutes prior to the final inspection of the repair.

Apply rear window defroster repair to the area as needed.

Heated Window Grid Wire Repair

Heated Window Grid Wire Repair

Material

Item

Specification

Dark Walnut Metallic Acrylic

Lacquer Touch-up Paint

ALBZ-19500-5858A or

equivalent

ESR-M2-P100-

C

Rear Window Defroster Repair

D8AZ-19562-AA ...

Door Window Glass Adjustment - Height Stop Adjustment

Door Window Glass Adjustment - Height Stop Adjustment

1. Close the front door.

2. Loosen the screws.

3. Raise the door window glass to the desired height.

4. Tighten the screws.

Door Window Glass Adjustment -Stabilizer

1. Raise the door window ...

Other materials:

Removal

1. Drain the engine cooling system.

2. Remove the air cleaner outlet tube.

3. Disconnect the fuel line.

4. Disconnect the upper radiator hose from the water outlet connector.

5. Disconnect and remove the upper radiator hose.

6. Disconnect the acce ...

Cleaning

1. Fabricate a cleaning tool from a 1/8 inch diameter brazing rod.

2. Cut an abrasive pad from maroon colored 3M Scotch Brite with the

dimensions corresponding

to the coupling size.

3. Assemble the pad to the tool.

4. Coat the abrasive pad with PAG Refri ...

Assembly

1. NOTE: Universal joint service kits are to be installed as complete

assemblies only. Do not mix

components from other U-joint kits.

Install the bearing cup.

1. Start a new bearing cup into the driveshaft yoke.

Check the needle bearings for correct po ...