Ford Mustang (1999-2004) Service Manual: Removal

1. Remove the differential assembly from the differential housing. For additional information, refer to Differential Case in this section.

2. CAUTION: Record the torque necessary to maintain rotation of the drive pinion gear through several revolutions prior to removing the pinion flange (4851).

Remove the pinion flange. For additional information, refer to Drive Pinion Flange and Drive Pinion Seal in this section.

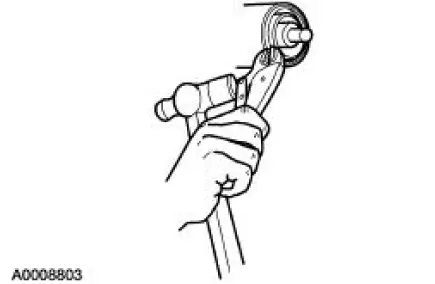

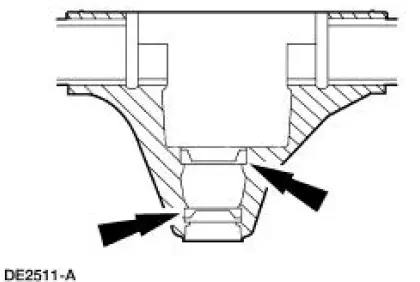

3. Force the rear axle drive pinion seal metal flange up. Install gripping pliers and strike with a hammer to remove the seal.

4. Remove the rear axle drive pinion shaft oil slinger (4670).

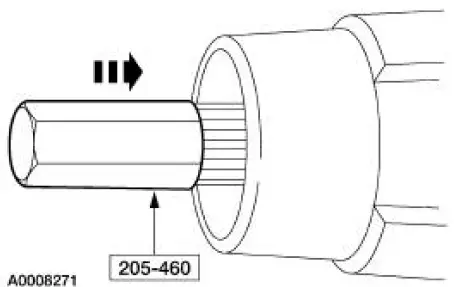

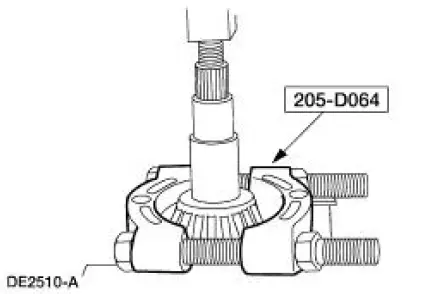

5. Using the special tool and a soft-faced hammer, drive the pinion assembly out of the outer differential pinion bearing (4621) and remove the drive pinion through the rear of the differential housing (4010).

6. Remove the outer differential pinion bearing.

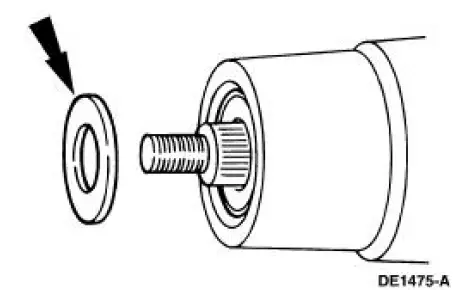

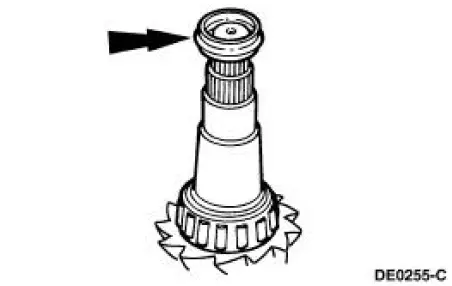

7. Remove and discard the collapsible spacer (4662).

8. Using the special tool and a suitable press, remove the inner differential pinion bearing (4630).

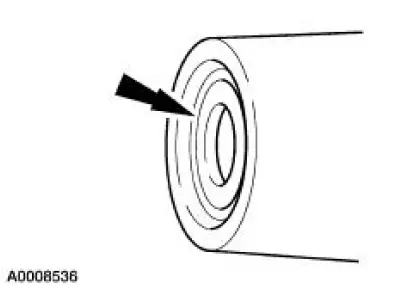

9. NOTE: Do not remove the pinion bearing cups from the differential housing unless the cups are damaged.

To remove the bearing cups, tap alternately (with a brass drift of suitable length) on opposite sides of the cup to prevent the cup from cocking in the casting.

Drive Pinion

Drive Pinion

Special Tool(s)

Adapter for 205-S127

205-105 (T76P-4020-A3)

Adapter for 205-S127

205-109 (T76P-4020-A9)

Adapter for 205-S127

205-110 (T76P-4020-A10)

Adapter fo ...

Installation

Installation

Using special tool 205-054

NOTE: This is the preferred method for installing the pinion bearing

cups. If necessary, proceed to

Using special tools 205-153, 205-054, and 205-D055 in this procedure for ...

Other materials:

Floor mats

WARNING: Always use floor mats that are designed to fit the

footwell of your vehicle. Only use floor mats that leave the pedal

area unobstructed. Only use floor mats that are firmly secured to

retention posts so that they cannot slip out of position and inter ...

Key Programming - Program a Key Using Two

Programmed Keys

Special Tool(s)

Worldwide Diagnostic System

(WDS)

418-F224,

New Generation STAR (NGS)

Tester

418-F052, or equivalent

diagnostic tool

NOTE: This procedure only works if two or more programmed ignition keys are

available and it is

desi ...

Booster seats

WARNING: Never place, or allow a child to place, the shoulder

belt under a child’s arm or behind the back because it reduces

the protection for the upper part of the body and may increase the risk

of injury or death in a crash.

Use a belt-positioning booster ...