Ford Mustang (1999-2004) Service Manual: Torque Converter End Play Check

Special Tool(s)

|

Dial Indicator Gauge with Holding Fixture 100-002 (TOOL-4201-C) or equivalent |

|

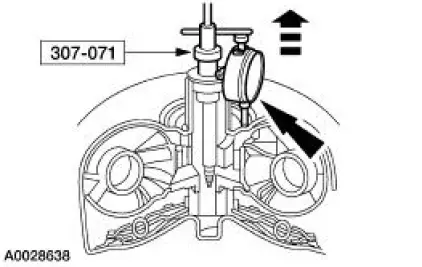

End Play Gauge, Torque Converter 307-071 (T80L-7902-A) or equivalent |

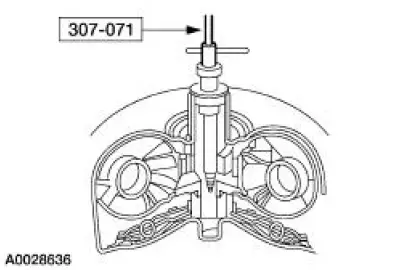

1. Install the special tool into the torque converter pump drive.

- Tighten the inner post until the tool is securely locked.

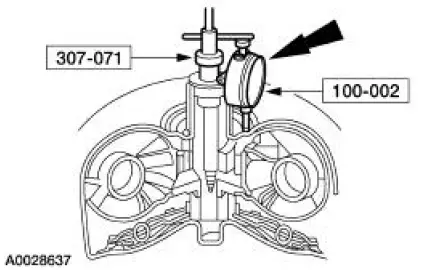

2. Install the special tool on the converter pump drive hub and zero the dial indicator.

3. Lift up on the special tool and note the dial indicator reading.

- If the reading exceeds end play limits, install a new or remanufactured torque converter.

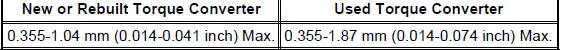

Torque Converter End Play

4. Remove the special tools.

Torque Converter One-Way Clutch Check

Special Tool(s)

|

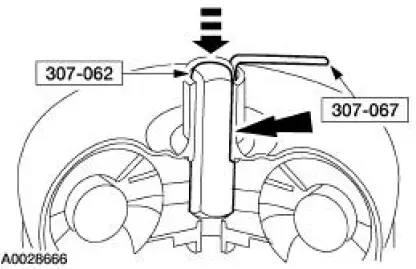

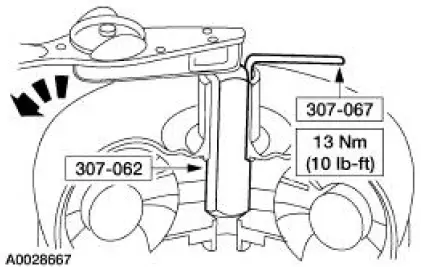

Holding Tool, One-Way Clutch 307-062 (T76L-7902-C) or equivalent |

|

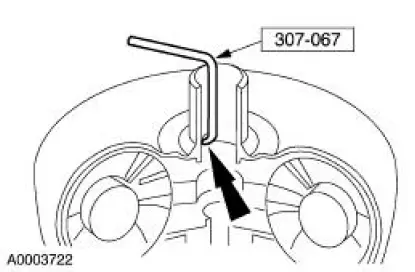

Holding Tool, Torque Converter Clutch 307-067 (T77L-7902-R) or equivalent |

1. Install the special tool in one of the grooves in the stator thrust washer.

2. Install the special tool in the converter pump drive.

3. Use a torque wrench to turn the special tool counterclockwise while holding the special tool stationary.

- The converter should lock up and hold torque.

- The torque converter one-way clutch should rotate freely in the clockwise direction.

- Try the clutch for lockup and hold in at least five positions.

- If the torque converter fails the lockup test torque, install a new or remanufactured torque converter.

Torque Converter Impeller to Pump Stator Interference

Check

Torque Converter Impeller to Pump Stator Interference

Check

1. NOTE: Front pump support may remain in front pump support and gear

during this test.

Position the front pump support with the splines up.

2. Mount the torque converter on the front pump support wi ...

Torque Converter Turbine to Pump Stator Interference

Check

Torque Converter Turbine to Pump Stator Interference

Check

1. NOTE: Front pump support may remain in front pump support and gear

during this test.

Position the torque converter with the pump drive up.

2. Install the front pump support to engage the mating sp ...

Other materials:

Driving Aids

STEERING

Electric Power Steering

WARNING: The electric power steering system has diagnostic

checks that continuously monitor the system to ensure proper

operation. When a system error is detected a steering message will

appear in the information display.

WARNI ...

Subwoofer Speaker - Convertible

Removal and Installation

1. Remove the rear quarter trim panel. For additional information,

refer to Section .

2. Remove the subwoofer assembly.

1. Disconnect the electrical connectors.

2. Remove the screws.

3. Remove the subwoofer assemb ...

Inspection and Verification

1. Verify the customer concern.

2. Visually inspect for obvious signs of mechanical and electrical damage.

Visual Inspection Chart

Mechanical

Electrical

Fuel tank

Engine coolant level

Accessory drive belt

Engine oil level

Par ...