Ford Mustang (1999-2004) Service Manual: Valve - Seat Inspection

Valve and Seat Refacing Measurements

CAUTION: After grinding valves or valve seats, check valve clearance.

1. Check the valve head and seat.

- Check valve angles.

- Check margin width.

- Refer to the appropriate section in Group 303 for the procedure.

- Be sure margin width is within specification.

2. Inspect for abnormalities on the valve face and seat.

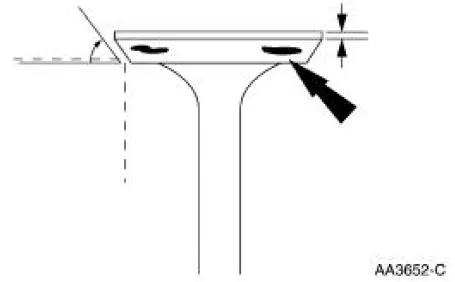

Valve -Seat Width

1. Measure the valve seat width. If necessary, grind the valve seat to specification.

- Measure the intake valve seat width.

- Measure the exhaust valve seat width.

- Recheck the valve spring installed length after the seats have been ground, and shim the valve springs as necessary to achieve the correct installed spring length.

- Refer to the appropriate section in Group 303 for the procedure.

Valve -Seat Runout

1. Use the Valve Seat Runout Gauge to check valve seat runout.

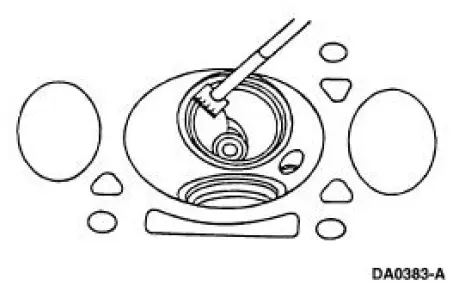

Valve Spring Strength

Valve Spring Strength

Special Tool(s)

Pressure Gauge, Valve/Clutch

Spring

303-006 (TOOL-6513-DD) or

equivalent

1. Use a Valve/Clutch Spring Pressure Gauge to check the valve spring for

correct strength ...

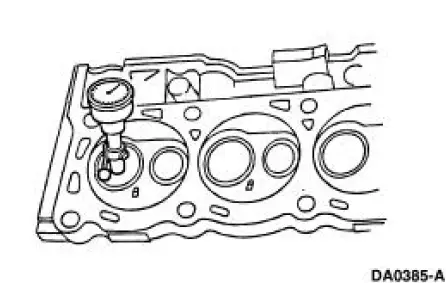

Cylinder Head - Distortion

Cylinder Head - Distortion

Special Tool(s)

Straight Edge

303-D039 (D83L-4201-A) or

equivalent

1. Use a straight edge and a feeler gauge to inspect the cylinder head for

flatness. If the cylinder

head is disto ...

Other materials:

Stoplamps

Refer to Wiring Diagrams Cell 90 , Turn/Stop/Hazard Lamps for

schematic and connector information.

Special Tool(s)

73III Automotive Meter or

equivalent

105-R0057

Inspection and Verification

1. Verify the customer concerns.

2. Visually ...

Oil Pan

Special Tool(s)

Compressor, Coil Spring

204-D001 (D78P-5310-A)

Lifting Bracket, Engine

303-D088 (D93P-6001-A2)

3-Bar Engine Support Kit

303-F072

Material

Item

Specification

Metal Surface Cleaner

F4 ...

Supply Manifold

Removal and Installation

WARNING: Do not smoke or carry lighted tobacco or open flame of any

type when

working on or near any fuel related components. Highly flammable mixtures are

always present

and may ignite. Failure to follow these instructions may resul ...