Ford Mustang (1999-2004) Service Manual: Assembly

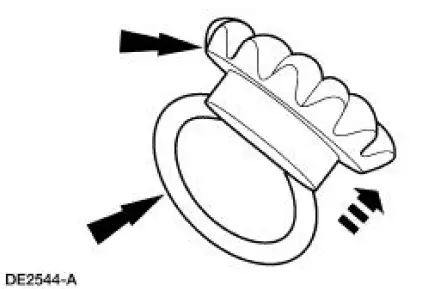

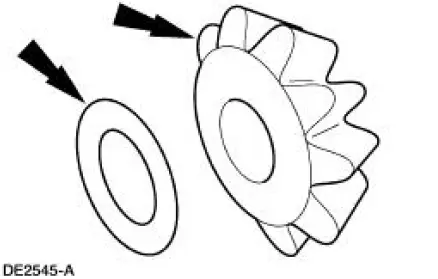

1. Lubricate the differential side gear thrust washers and the differential side gear journals, and assemble the washers to the gears.

- Use SAE 80W-90 Premium Rear Axle Lubricant XY-80W90-QL or equivalent meeting Ford specification WSP-M2C197-A.

2. Lubricate the differential pinion thrust washers and the differential pinion gears, and assemble the washers to the gears.

- Use SAE 80W-90 Premium Rear Axle Lubricant XY-80W90-QL or equivalent meeting Ford specification WSP-M2C197-A.

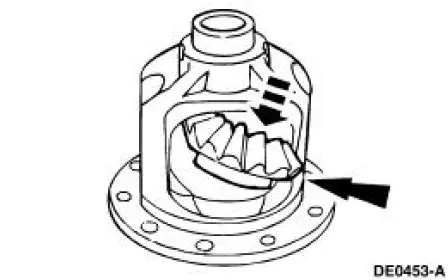

3. Position the differential side gear and thrust washer assemblies in the differential case.

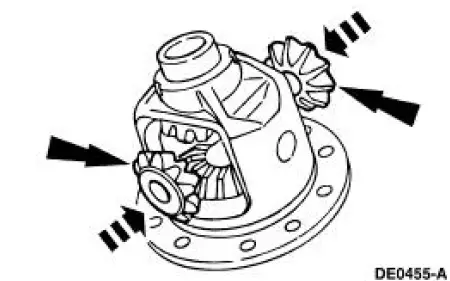

4. Engage the differential pinion gears with the differential side gears and rotate the pinion gears to align with the differential pinion shaft bore.

5. Insert the differential pinion shaft.

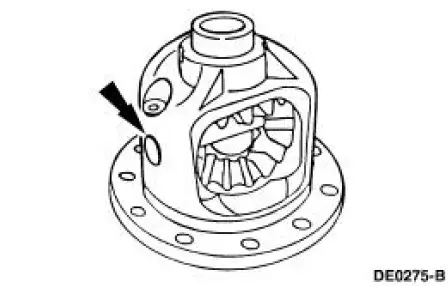

- Align the hole in the differential pinion shaft with the hole in the differential case.

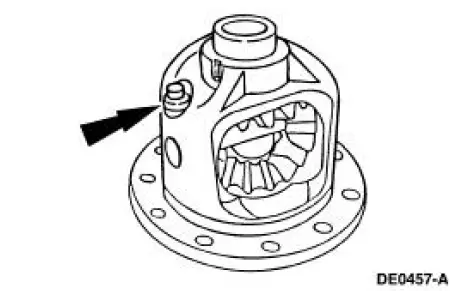

6. NOTE: If a new bolt is unavailable, coat the original bolt threads with Threadlock and Sealer EOAZ-19554-AA or equivalent meeting Ford specifications WSK-M2G351-A5 prior to installation.

Install a new bolt finger-tight.

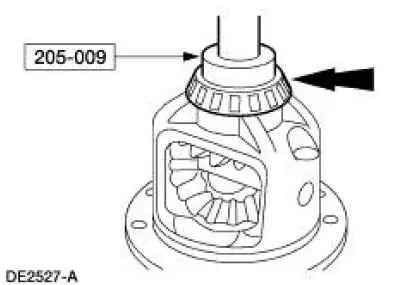

7. Using the special tool, install the new differential bearings, if removed.

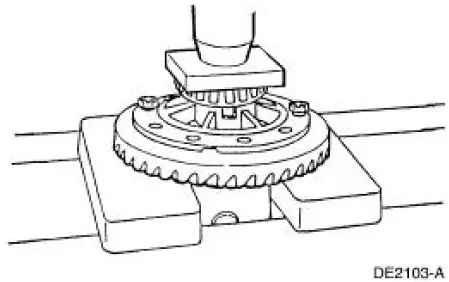

8. Position the ring gear and the differential case. Align the bolt holes by starting two bolts through the holes in the differential case and the ring gear. Press the ring gear on the differential case.

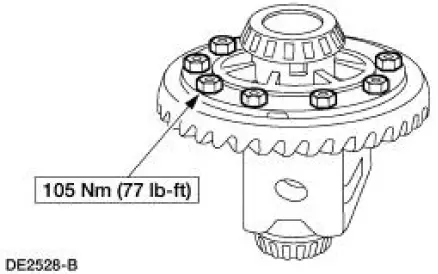

9. Install the bolts.

- Apply Stud and Bearing Mount EOAZ-19554-BA or equivalent meeting Ford specification WSK-M2G349-A1 to the bolt threads.

10. Install the differential case. For additional information, refer to Differential Case in this section.

Disassembly

Disassembly

1. Remove the differential assembly from the differential housing. For

additional information, refer

to Differential Case in this section.

2. Remove the bolts.

3. CAUTION: Do not damage the thread ...

Rear Drive Axle/Differential - Ford 8.8-Inch Ring Gear

Rear Drive Axle/Differential - Ford 8.8-Inch Ring Gear

General Specifications

Torque Specifications

Description

Nm

lb-ft

lb-in

Bolt retaining the differential pinion shaft to the

differential case

30

22

-

Bolt retaining t ...

Other materials:

Removal

WARNING: Do not smoke or carry lighted tobacco or open flame of any

type when

working on or near any fuel related components. Highly flammable mixtures are

always present

and may be ignited. Failure to follow these instructions may result in personal

injury ...

Auxiliary input jack

WARNING: Driving while distracted can result in loss of vehicle

control, crash and injury. We strongly recommend that you use

extreme caution when using any device that may take your focus off

the road. Your primary responsibility is the safe operation of your ...

Engine (Assembly)

Special Tool(s)

Guides, Connecting Rod

303-442 (T93P-6136-A)

Installer, Crankshaft Rear Oil

Seal

303-518 (T95P-6701-DH)

Installer, Crankshaft Rear Oil

Seal

303-516 (T95P-6701-BH)

Installer, Crankshaft Re ...