Ford Mustang (1999-2004) Service Manual: Transmission Case

Special Tool(s)

|

Handle 205-D055 (D81L-4000-A) |

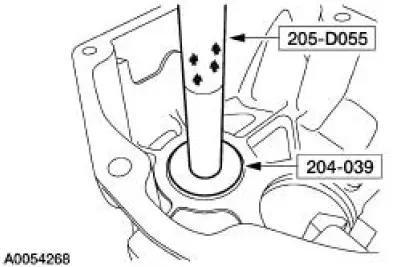

|

Installer, Bearing Cup 204-039 (T77F-1217-B) |

|

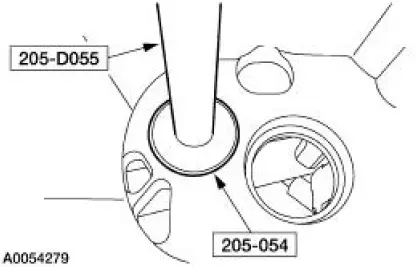

Installer, Drive Pinion Bearing Cup 205-054 (T71P-4616-A) |

|

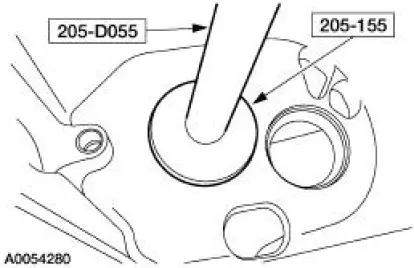

Installer, Rear Axle Oil Seal 205-155 (T80T-4000-Y) |

Disassembly and Assembly

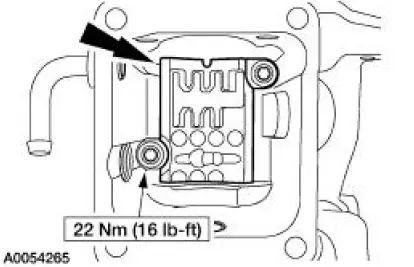

1. Remove the bolts and the guide plate.

- Inspect the plate for wear or damage. Install a new plate as necessary.

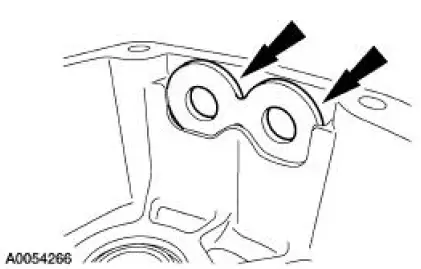

2. Remove the case magnets.

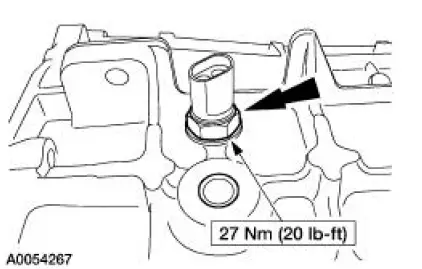

3. Remove the reverse lamp switch.

4. Using the special tools, remove the countershaft bearing cup.

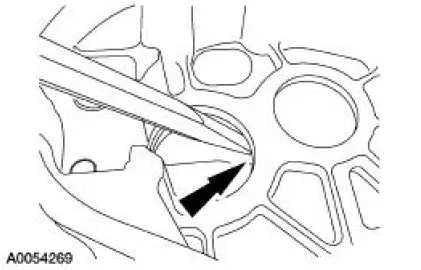

5. Using a brass drift, remove mainshaft bearing cup.

6. Inspect the countershaft and mainshaft bearing cups for wear or damage. Install new components as necessary.

7. WARNING: Make sure protective eye wear is in place.

Clean the case with solvent and dry with compressed air. Clean and check the sealing surface for nicks or scratches. Inspect the case for cracks.

- If the case is cracked, install a new case. If the sealing surface has nicks or scratches, use a soft stone or crocus cloth to remove.

8. NOTE: If a new countershaft bearing is being installed, install a new bearing cup. Always install new bearings and cups in a set.

Using the special tools, install the countershaft bearing cup.

9. NOTE: If a new mainshaft bearing is being installed, install a new bearing cup. Always install new bearings and cups in a set.

Using the special tools, install the mainshaft bearing cup.

10. To assemble, reverse the disassembly procedure.

Extension Housing

Extension Housing

Special Tool(s)

Installer, Bearing Cup

204-039 (T77F-1217-B)

Adapter for 303-224 (Handle)

205-153 (T80T-4000-W)

Disassembly and Assembly

1. Remove the bolt and ...

Transmission (Assembly)

Transmission (Assembly)

Special Tool(s)

Dial Indicator Gauge with

Holding Fixture

100-002 (TOOL-4201-C) or

equivalent

Holding Fixture, Transmission

307-003 (T57L-500-B)

Remover/Inst ...

Other materials:

Water Pump

Removal and Installation

1. Disconnect the battery ground cable.

2. Drain the coolant. For additional information, refer to Supercharger Cooling

System Draining,

Filling and Bleeding in this section.

3. Remove the retainer and position the inner fender well ...

Cleaning the exterior

Wash your vehicle regularly with cool or lukewarm water and a neutral

pH shampoo, such as Motorcraft® Detail Wash.

• Do not use a commercial or high-pressure wand on the surface or

edge of stripes and graphics. This can cause damage to the film and

cause th ...

Ignition Switch Lock Cylinder - Functional

Removal and Installation

1. Disconnect the battery ground cable.

2. Remove the ignition switch lock cylinder (11582).

1. Insert the ignition key and turn to the RUN position.

2. Using a 1/8-inch drift, press the ignition switch lock cylinder release

...