Ford Mustang (1999-2004) Service Manual: Assembly

1. Inspect the clutch cylinder thrust surfaces, piston bore and clutch plate serrations for scores or burrs. Minor scores or burrs may be removed with crocus cloth. Install a new clutch cylinder if badly scored or damaged.

2. Check the fluid passage in the clutch cylinder for obstructions. Clean out all fluid passages.

Inspect the clutch piston for scores and install a new piston if necessary. Inspect check balls for freedom of movement and correct seating.

3. Check the clutch release spring for distortion and cracks. Install a new spring (including the wave spring) if distorted or cracked.

4. Inspect composition clutch plates, steel clutch plates and clutch pressure plate for worn or scored bearing surfaces. Install new parts if they are deeply scored or burred.

5. Check the clutch plates for flatness and fit on the clutch hub serrations. Discard any plate that does not slide freely on serrations or that is not flat.

6. Check the clutch hub thrust surfaces for scores and the clutch hub splines for wear.

7. NOTE: To aid handling, the forward clutch assembly may be set in the extension housing or a hole in the work bench.

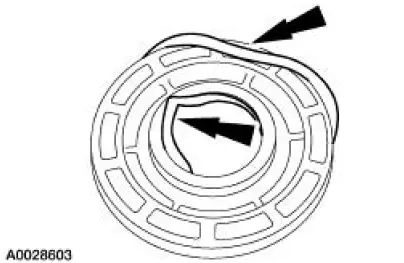

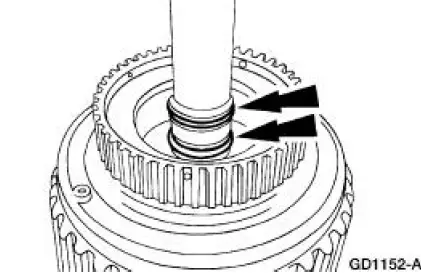

Install the inner and outer forward clutch piston seals. Note the direction of the sealing rings before installation.

8. NOTE: Coat the piston seals and clutch drum sealing area with petroleum jelly.

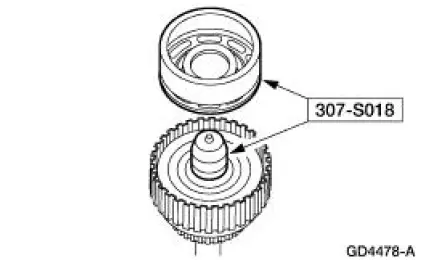

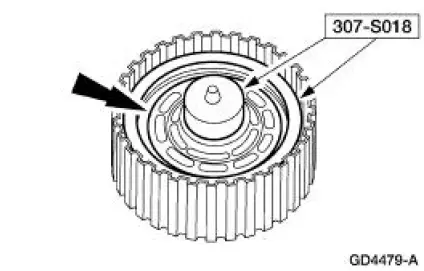

Position the special tools on the clutch piston.

9. Using the special tools, install the forward clutch piston into the clutch drum.

- Push the piston to the bottom of the drum using even pressure.

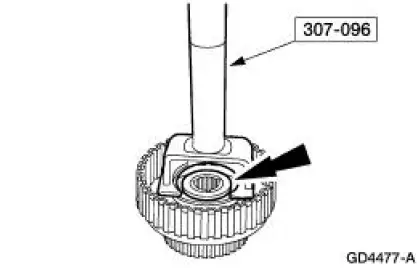

10. Using the special tool, compress the piston return spring and install the retaining ring.

11. Slowly release the press pressure and remove the forward clutch.

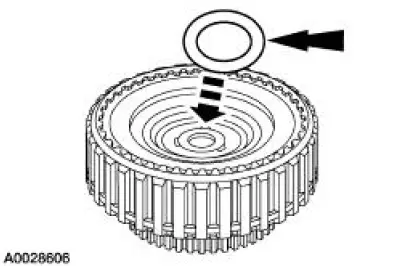

12. NOTE: Before assembly, soak the new clutch discs in clean automatic transmission fluid for 15 minutes.

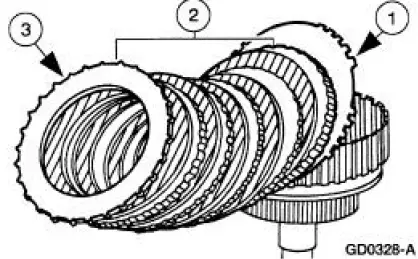

Install the clutch pack assembly.

1. Install the pressure ring.

2. Install the clutch pack.

3. Install the pressure plate.

13. Install the clutch pack retaining ring.

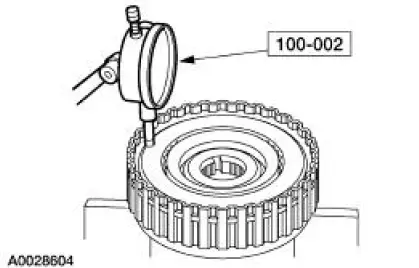

14. Install the special tool on the forward clutch pack.

- Push downward on the clutch pack.

- Release pressure and zero the dial indicator.

15. Using the special tool, check the clutch pack clearance.

1. Lift up on the clutch pack until it fully seats against the clutch pressure plate retainer.

2. Read the dial indicator.

- If the clearance is not within specifications, install the correct size retaining ring.

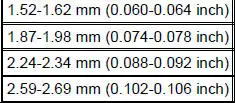

Selective Retaining Ring

Specification

16. NOTE: Make sure the scarf-cut seals are mated correctly.

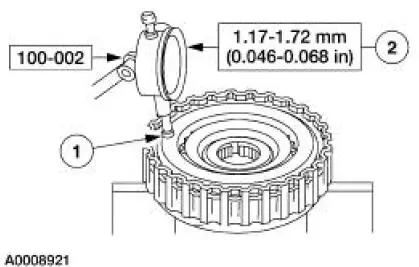

Slide the two scarf-cut seals on the input shaft.

17. Install the two scarf-cut seals on the input shaft.

18. Install the No. 3 forward clutch hub front bearing and the forward clutch hub.

Disassembly

Disassembly

1. Inspect the clutch cylinder thrust surfaces, piston bore and clutch plate

serrations for scores or

burrs. Minor scores or burrs may be removed with crocus cloth. Install a new

clutch cylinder if ...

Planetary Gear Support Assembly and Planetary One-Way

Clutch

Planetary Gear Support Assembly and Planetary One-Way

Clutch

Disassembly and Assembly

1. NOTE: Inspect the outer and inner races for scores or damaged

surface areas where rollers

contact the races. Inspect the rollers and springs for excessive wear ...

Other materials:

Fuel Vapor Control Tube Assembly Valve

Removal and Installation

1. Remove the fuel tank. For additional information, refer to

Section.

2. Remove the retainers.

3. NOTE: The fuel vapor vent valve, fuel vapor control valve and the

in-line fuel tank pressure

sensor are repaired as a fuel va ...

Summer tires (if equipped)

Summer tires provide superior performance on wet and dry roads. Summer

tires do not have the Mud and Snow (M+S or M/S) tire traction rating on the

tire side wall. Since summer tires do not have the same traction performance

as All-season or Snow tires, Ford do ...

Installation

Using special tool 205-024

NOTE: This is the preferred method for installing the pinion bearing

cups. If necessary, proceed to

Using special tools 205-153, 205-024, 205-231, and 205-D055 in this procedure

for an alternate

method.

1. Position the special too ...